Method for separating and extracting boron from boron-containing solution

A solution and raw material liquid technology, applied in ion exchange column/bed methods, chemical instruments and methods, ion exchange, etc., can solve the problems of high energy consumption, unreasonable technology and economy, and achieve comprehensive energy consumption reduction and improved feasibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

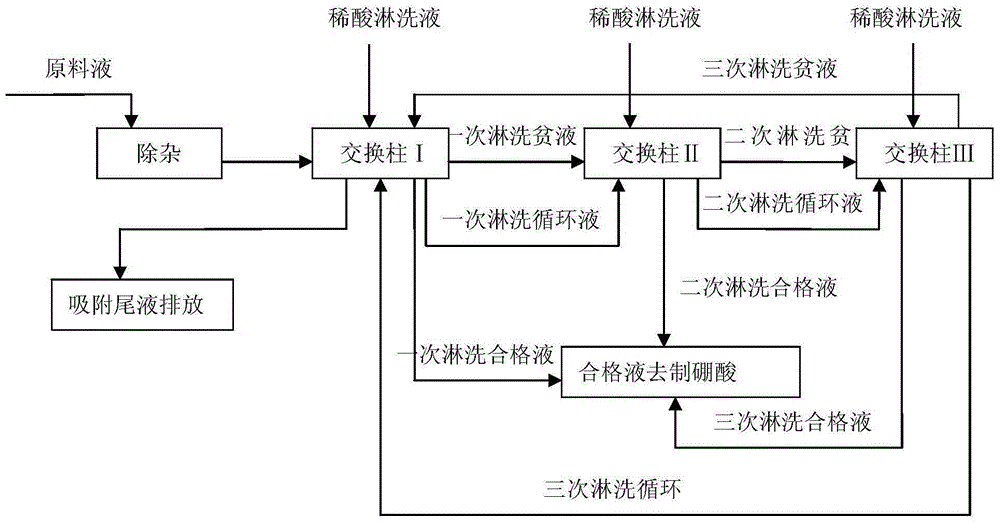

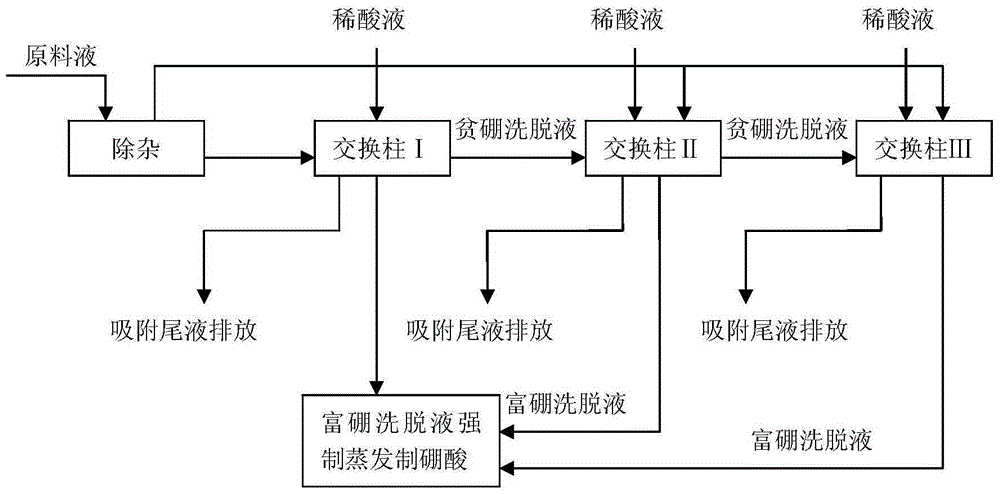

Method used

Image

Examples

Embodiment 1

[0022] B 2 o 3 The boron-containing raw material solution with a concentration of 1000mg / L is treated by removing insolubles, that is, after impurity removal treatment, and flows through the ion exchange column I at a speed of 0.1BV / h, and the tail liquid is adsorbed for discharge. When the B in the adsorption tail liquid 2 o 3 Concentration drops to raw material solution B 2 o 3 When the concentration is 10%, stop the adsorption, use 1mol / L HCl eluent to elute the boron on the exchange column at a speed of 0.1BV / h, elute the boron in the exchange column, and collect B 2 o 3 The eluent with a concentration >20g / L is called a qualified eluent, and the qualified liquid is used to produce boric acid; collect B 2 o 3 The eluent with a concentration ≥ 20g / L ≤ 15g / L is called the primary eluent circulating fluid, which is used as the eluent after the exchange column II is saturated and adsorbed, and the collected B 2 o 3 The eluent with a content of 2 o 3 When the concentra...

Embodiment 2

[0024] B 2 o 3 The boron-containing raw material solution with a concentration of 1500mg / L is treated by removing insoluble matter, that is, after impurity removal treatment, it flows through the ion exchange column I at a speed of 0.5BV / h, and the tail liquid is adsorbed for discharge. 2 o 3 The concentration rises to B in the raw material solution 2 o 3 When the concentration is 5%, stop the adsorption, use 1mol / L HCl eluent to elute the boron on the exchange column at a speed of 0.5BV / h, elute the boron in the exchange column, and collect B 2 o 3 The eluent with a concentration >20g / L is called a qualified eluent, and the qualified liquid is used to produce boric acid; collect B 2 o 3 The eluent with a concentration ≥ 20g / L ≤ 15g / L is called the primary eluent circulating fluid, which is used as the eluent after the exchange column II is saturated and adsorbed, and the collected B 2 o 3 The eluent with a content of 2 o 3 When the concentration is less than 15g / L, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com