Method for operating a large diesel engine, use of this method and large diesel engine

A diesel engine, dual-fuel engine technology, applied in the direction of engine components, combustion engines, engine control, etc., can solve the problem that the exhaust gas value can no longer be maintained, and achieve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

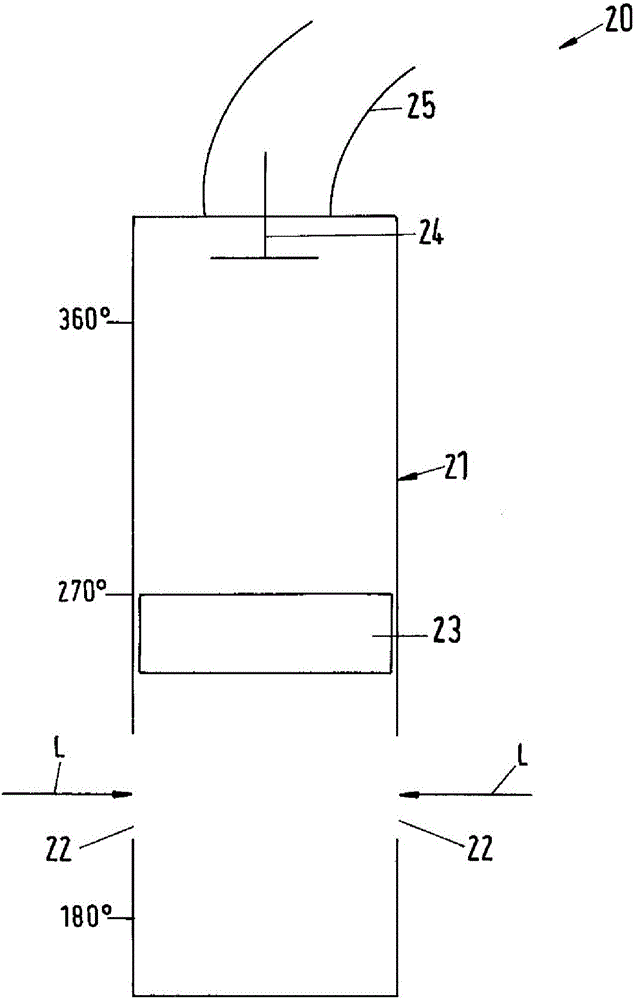

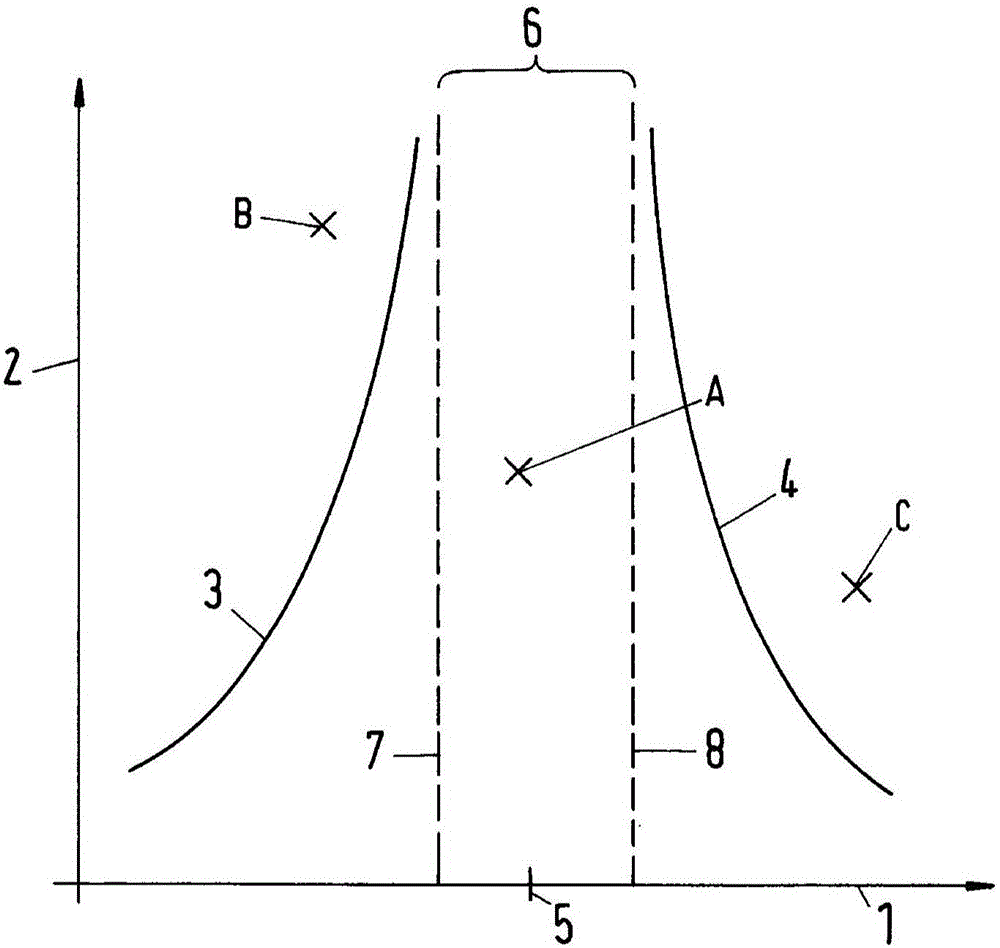

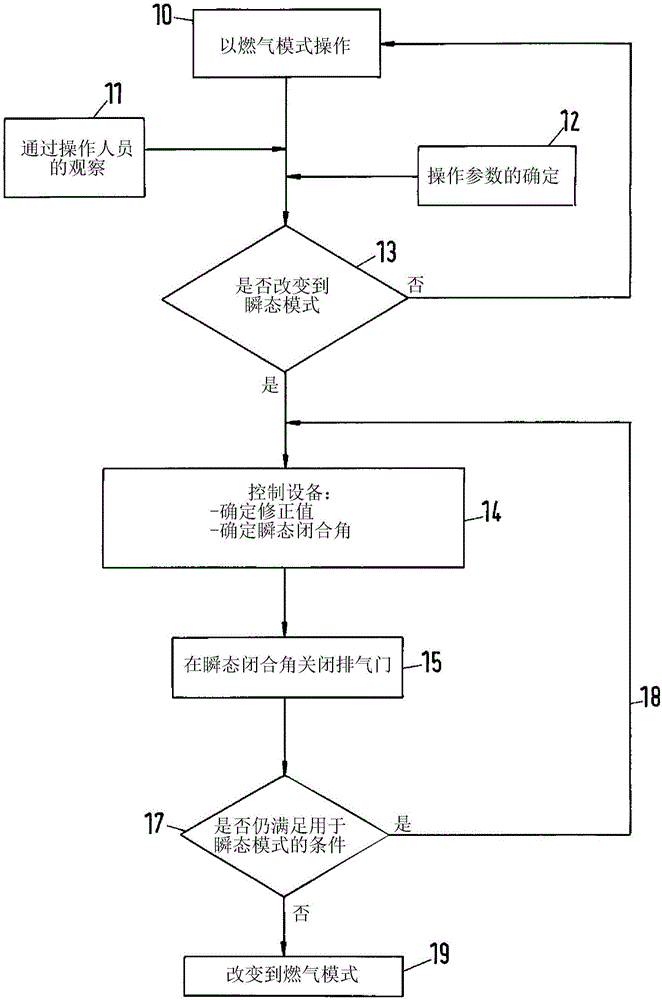

[0054] In the following description of the invention with reference to embodiments, reference will be made, with exemplary features, to a particularly important application in practice of a large diesel engine, which is constructed as a dual-fuel engine, meaning a dual-fuel engine capable of An engine that operates on two different types of fuel. In particular, this embodiment of a large diesel engine is capable of operating in a liquid mode in which only liquid fuel is injected into the combustion space of the cylinder. Typically, liquid fuel (such as heavy fuel oil or diesel) is directly injected into the combustion space at a suitable point in time and ignited in the combustion space according to the principle of diesel self-ignition. However, the large diesel engine can also be operated in a gas-fired operating mode, in which gas used as fuel, such as natural gas, is introduced into the combustion space in the form of an air-gas mixture and ignited there. In particular, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com