Manufacturing method of three-dimensional fixation plate for repairing fracture lower jawbone and three-dimensional fixation plate

A manufacturing method and technology of mandible, applied in the direction of fixator, outer plate, internal bone synthesis, etc., can solve the problem of inability to guarantee retention force and stability, achieve good retention force and stability, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The three-dimensional fixation method for repairing the fractured mandible according to the present invention comprises the following steps:

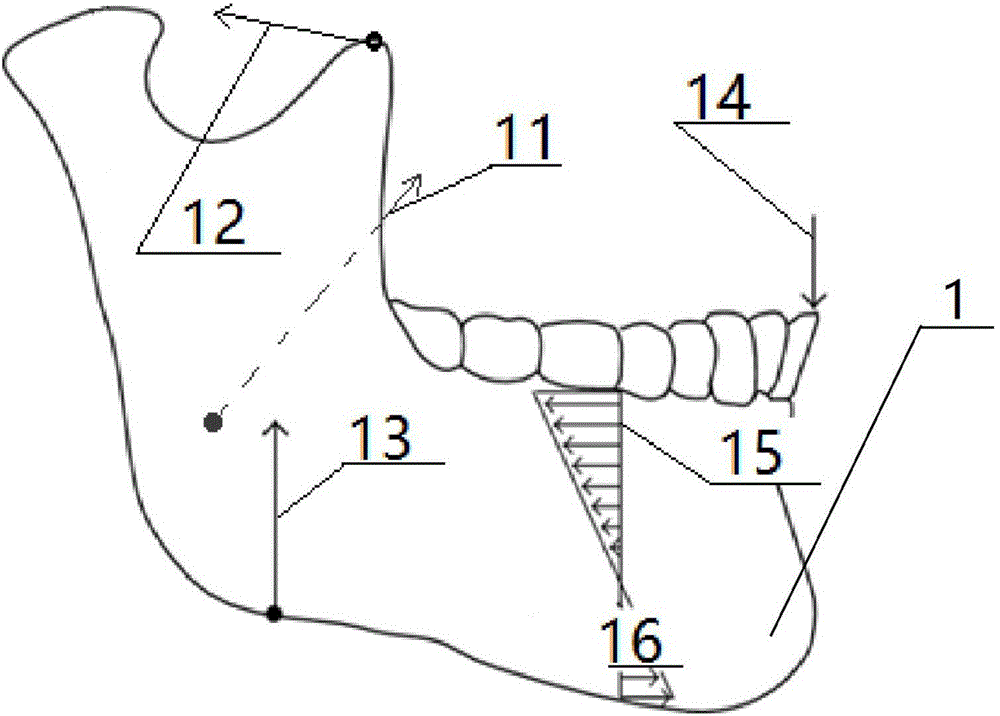

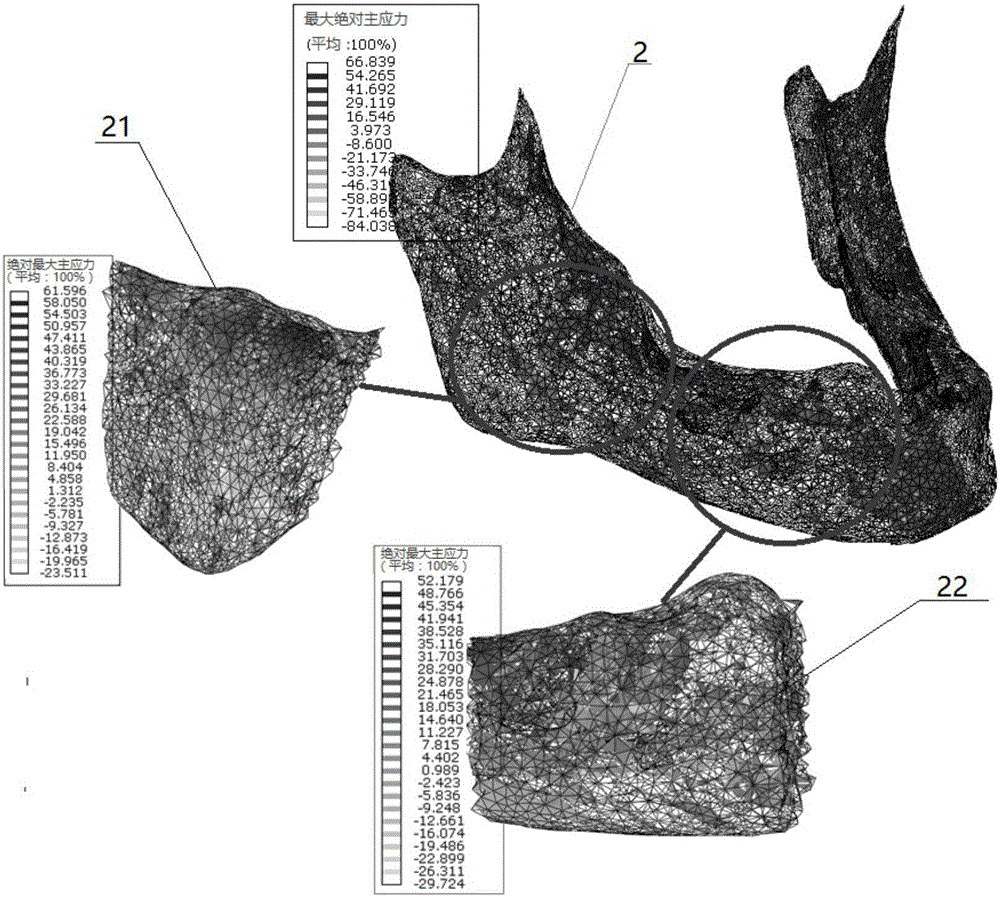

[0034] 1) Construct the biomechanical model 1 of the standard mandible, and establish the stress distribution under the occlusal force in different regions figure 2 , and then formulate the principles of fracture fixation in different regions:

[0035] (1) Select a typical mandible, obtain its CT data, and obtain its three-dimensional surface model (triangular mesh) and solid mesh model (tetrahedral mesh) through medical image processing and model reconstruction;

[0036] (2) Calculate the bone density value of each voxel of the mandible according to the relationship function between the gray value on the CT image and the bone density, and complete the voxel Young's modulus according to the relationship function between the bone density and the Young's modulus The calculation of the solid mesh model is performed, a...

Embodiment 2

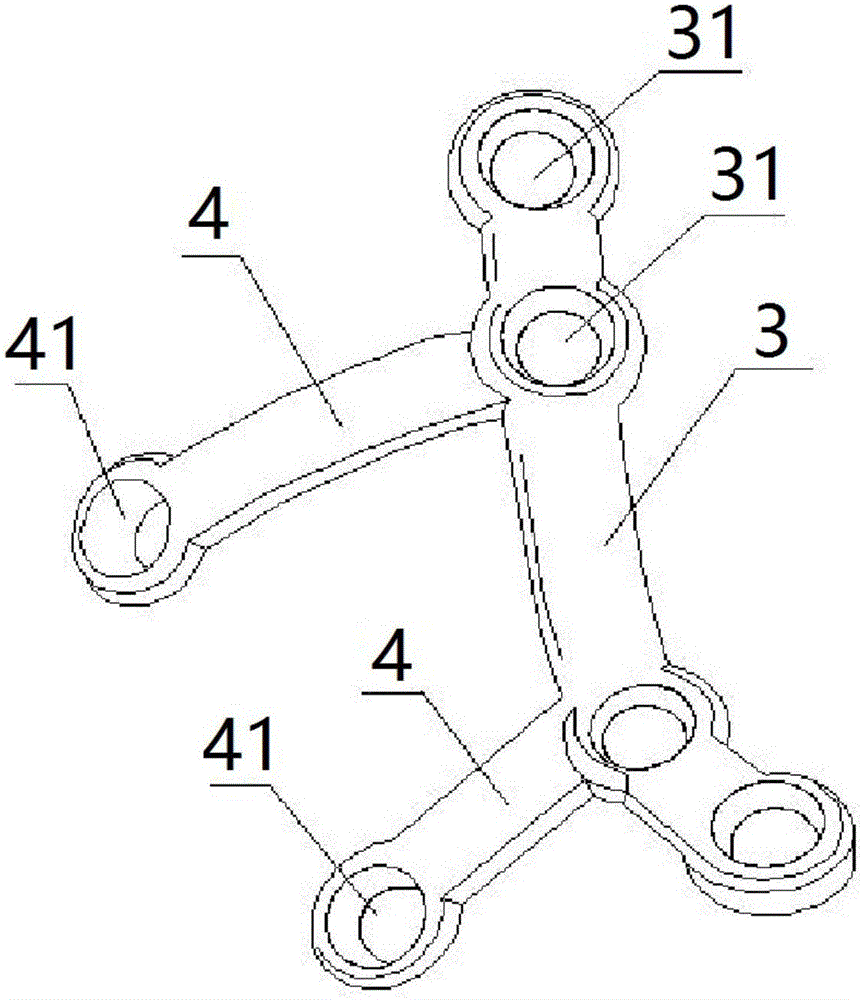

[0047] Embodiment 2 The three-dimensional fixation plate constructed according to the three-dimensional fixation method for repairing the fractured mandible described in Example 1 includes a main connecting plate 3 and a plurality of auxiliary connecting plates 4 for connecting the mandibular fracture to be repaired. The main connecting plate 3 is distributed along the direction of the connecting plate with a number of main installation through holes 31 for fixing on the mandible to be repaired, the auxiliary connecting plate 4 is arranged on the side of the main connecting plate 3, and the The auxiliary connecting plate 4 is provided with an auxiliary installation through hole 41 for fixing on the mandible, and the main connecting plate 3 and the auxiliary connecting plate 4 are all attached to the outer surface of the mandible to be repaired. The main connecting plate 3 and the auxiliary connecting plate 4 are affixed to the mandible 5 to be repaired through titanium nails. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com