Extraction method of siraitia grosvenorii fruits and siraitia grosvenorii fruit composition

An extraction method, the technology of Luo Han Guo, applied in the direction of drug combination, separation method, chemical instrument and method, etc., can solve the problems of low content of active ingredients, large dosage for patients, inconvenient taking, etc., and achieve stable active ingredients, strong applicability, Solve the effect of low drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

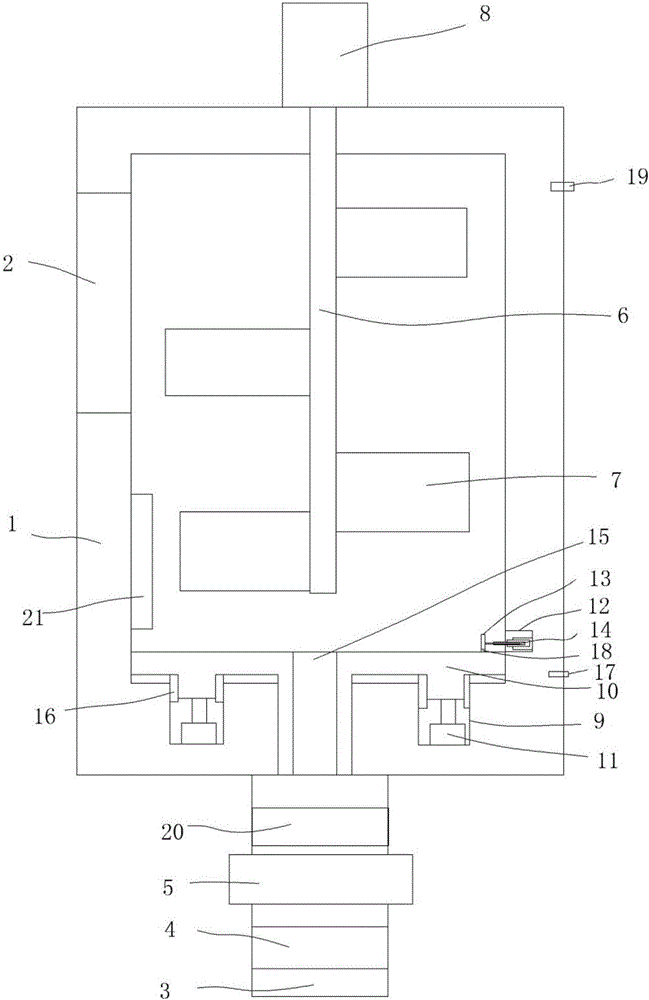

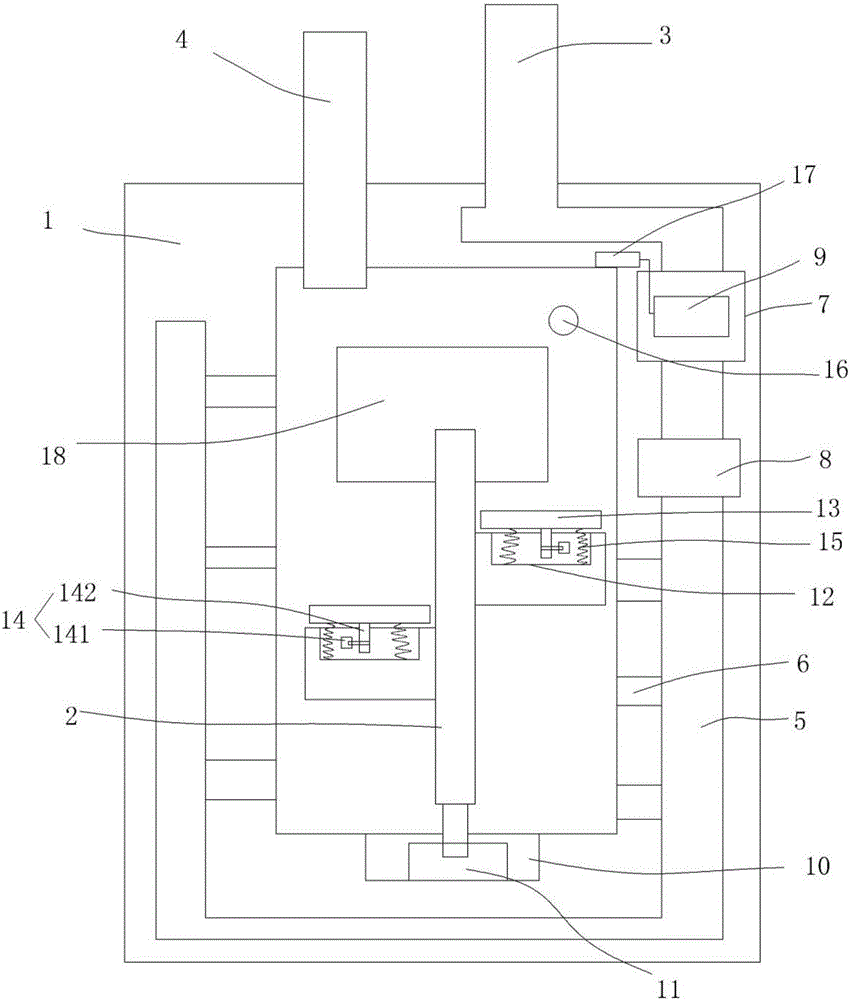

Method used

Image

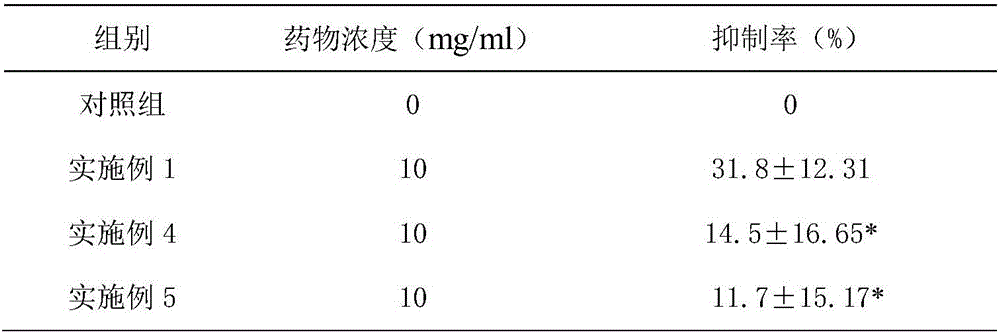

Examples

Embodiment 1

[0021] Take 1000g of Luo Han Guo, wash it quickly, cut it into sections, dry it in the sun, take it out, add 10 times the weight of water, soak it for 0.5h, decoct it for 1 hour, filter it, add the dregs of the medicine, add water 8 times the weight of the medicinal material, and decoct it for 1 hour, Filter out the medicinal liquid, combine two decoction liquids, concentrate to 60°C with a relative density of 1.05, add ethanol so that the volume percentage of alcohol content reaches 75%, stir, stand still, filter, and when the filtrate is concentrated to 65°C, the relative density is 1.25, and recover ethanol to obtain a concentrated solution, which is refined with silica gel to obtain an effluent, which is further concentrated, dried and granulated to obtain Luo Han Guo granules.

[0022] The extraction method of Luo Han Guo, the silica gel refining method is as follows: pre-load the selected silica gel into a resin column, and at the same time dilute the concentrated solutio...

Embodiment 2

[0034] Take 1000g of Luo Han Guo, wash it quickly, cut it into sections, dry it in the sun, take it out, add 10 times the weight of water, soak it for 0.5h, decoct it for 1 hour, filter it, add the dregs of the medicine, add water 8 times the weight of the medicinal material, and decoct it for 1 hour, Filter out the medicinal liquid, combine two decoction liquids, concentrate to 60°C with a relative density of 1.05, add ethanol so that the volume percentage of alcohol content reaches 75%, stir, stand still, filter, and when the filtrate is concentrated to 65°C, the relative density is 1.25, and recover ethanol to obtain a concentrated solution, which is refined with silica gel to obtain an effluent, which is further concentrated, dried and granulated to obtain Luo Han Guo granules.

[0035] The extraction method of Luo Han Guo, the silica gel refining method is as follows: pre-load the selected silica gel into a resin column, and at the same time dilute the concentrated solutio...

Embodiment 3

[0040] Take 1000g of Luo Han Guo, wash it quickly, cut it into sections, dry it in the sun, take it out, add 10 times the weight of water, soak it for 0.5h, decoct it for 1 hour, filter it, add the dregs of the medicine, add water 8 times the weight of the medicinal material, and decoct it for 1 hour, Filter out the medicinal liquid, combine two decoction liquids, concentrate to 60°C with a relative density of 1.05, add ethanol so that the volume percentage of alcohol content reaches 75%, stir, stand still, filter, and when the filtrate is concentrated to 65°C, the relative density is 1.25, and recover ethanol to obtain a concentrated solution, which is refined with silica gel to obtain an effluent, which is further concentrated, dried and granulated to obtain Luo Han Guo granules.

[0041] The extraction method of Luo Han Guo, the silica gel refining method is as follows: pre-load the selected silica gel into a resin column, and at the same time dilute the concentrated solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com