Novel full-automatic basket filter

A basket filter, fully automatic technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems that affect the working efficiency, easy to block, complex structure, etc., and achieve the safety factor of use High, ensure safe production, and stabilize the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

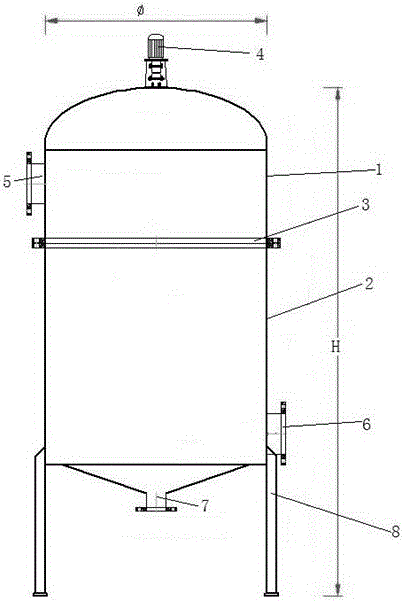

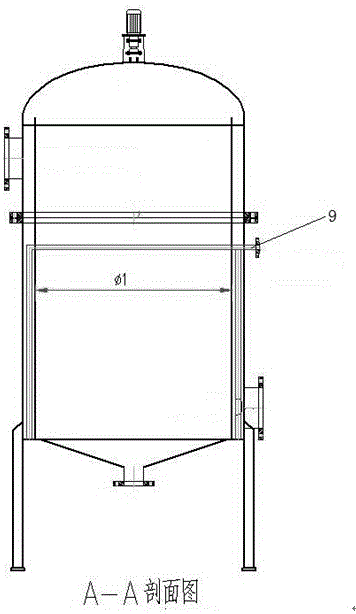

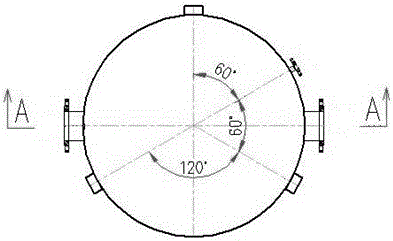

[0016] like figure 1 , figure 2 , image 3 and Figure 4 A new type of fully automatic basket filter shown includes legs 8, a filter cartridge 2 arranged on the legs 8, and a barrel cover 1 arranged on the filter cartridge 2, wherein the filter cartridge 2 and the barrel cover 1 are connected by flange 3, and the reducer 4 arranged on the barrel cover 1, and the water inlet 5 arranged on the side of the barrel cover 1, and the water outlet 6 arranged on the side of the filter cartridge 2, and arranged on the filter The sewage outlet 7 at the bottom of the cylinder 2; the height of the legs 8, the filter cylinder 2 and the barrel cover 1 is 2750mm, and the diameter Φ of the barrel cover 1 is 1200mm (the filter screen is not marked in the figure).

[0017] Further preferably, the new fully automatic basket filter also includes a pressure flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com