A metal-modified composite molecular sieve, its preparation method and its application in the reaction of methanol conversion to propylene and butene

A composite molecular sieve and metal modification technology, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, can solve the problem of reducing the selectivity of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

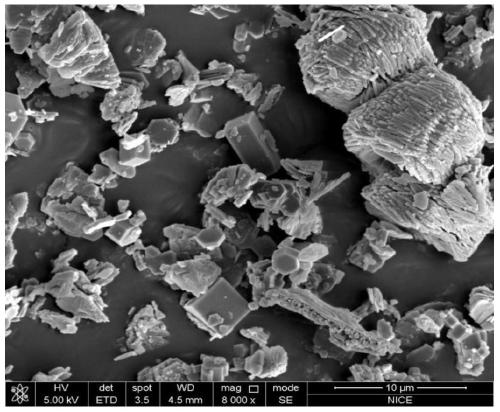

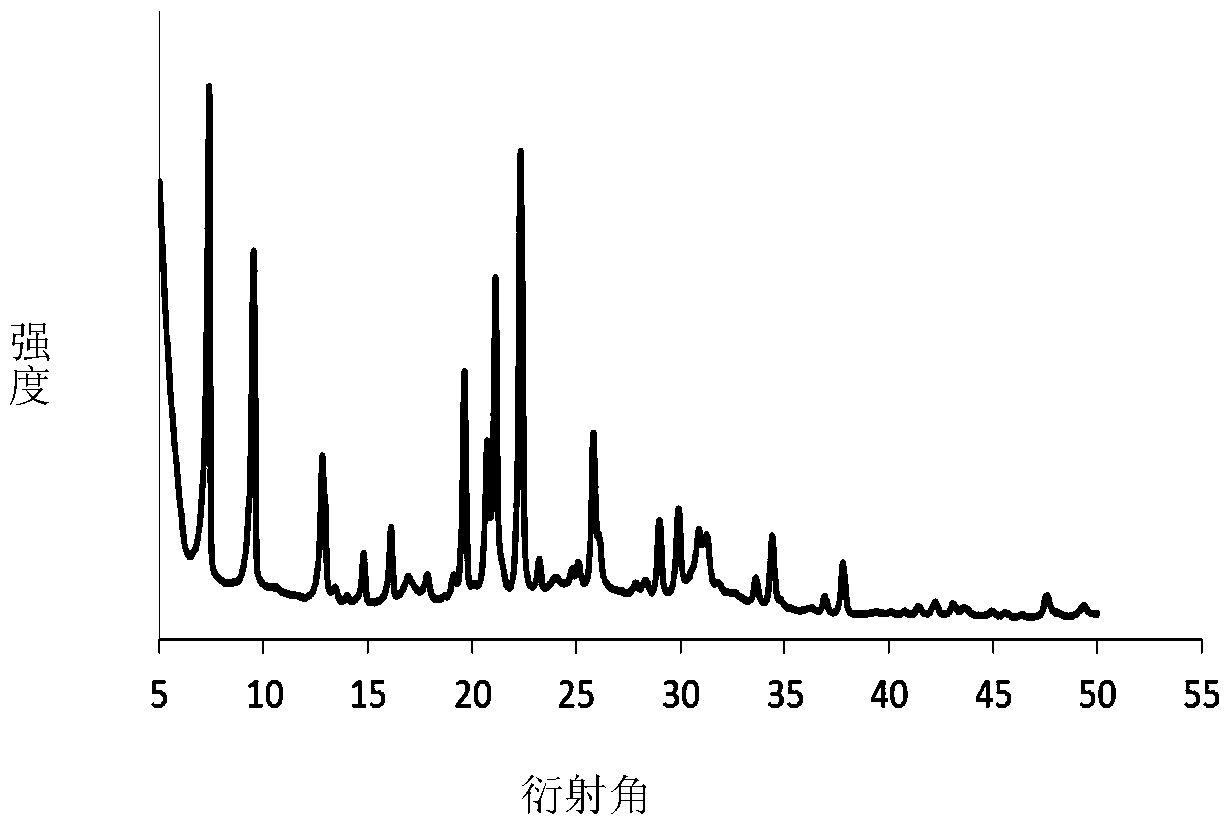

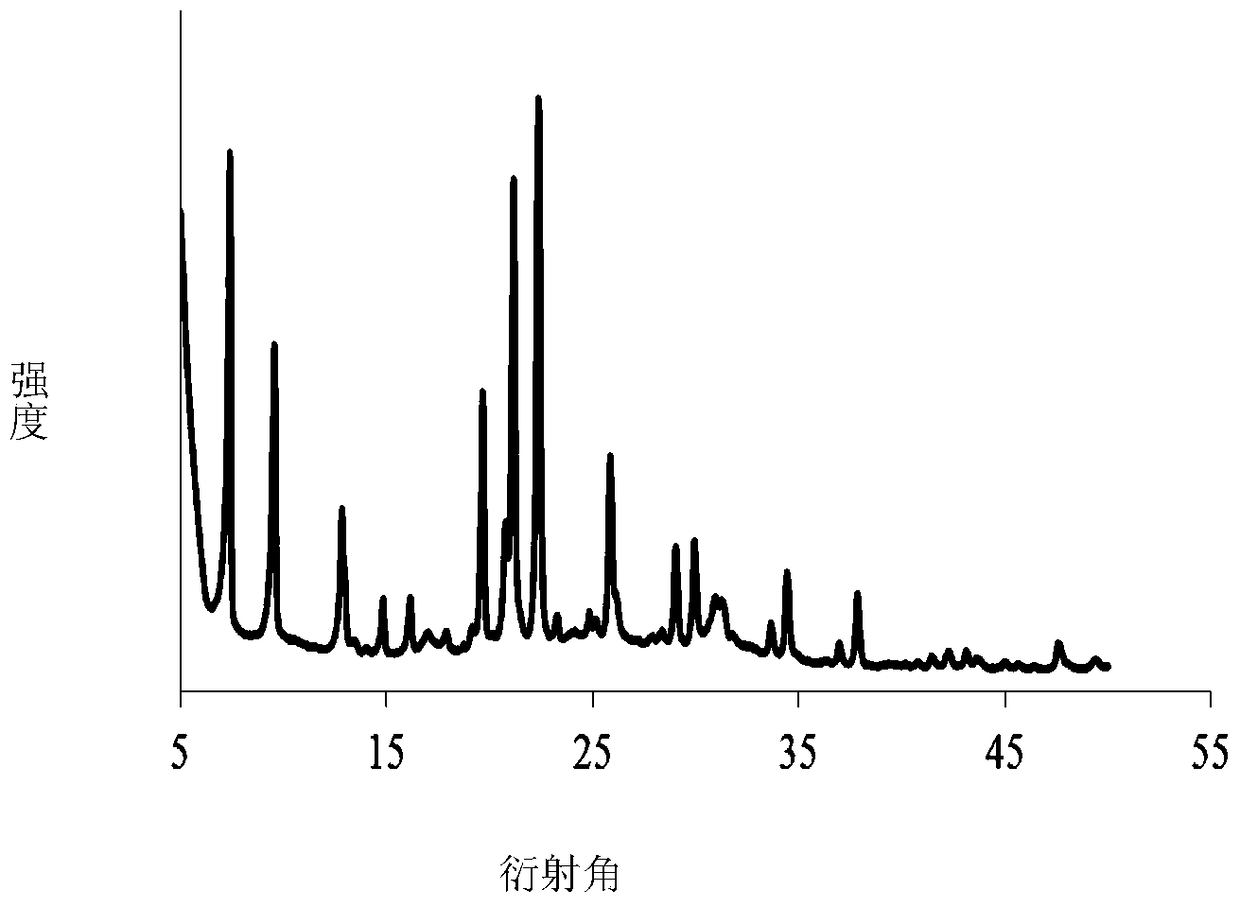

[0057] Embodiment 1: low content La modified SAPO-5 / SAPO-34 composite molecular sieve

[0058] 12 grams of pseudo-boehmite and 30.0 grams of deionized water are mixed and stirred to form an aluminum source solution, and 20 grams of phosphoric acid with a concentration of 85% by weight are mixed and stirred with 30.0 grams of deionized water to form a phosphorus source solution. The concentration of 2.5 grams is 40% by weight of silica sol and 4.5 grams of deionized water were mixed and stirred to form a silicon source solution.

[0059] Then, the phosphorus source solution is slowly added dropwise to the aluminum source solution to form a mixed solution of the aluminum source and the phosphorus source, stirred evenly for 1 hour, then the silicon source solution is added to the mixed solution of the aluminum source and the phosphorus source, and stirred evenly for 1 hour Hour, form the mixed solution of silicon source, aluminum source and phosphorus source, continue to stir for...

Embodiment 2

[0063] Embodiment 2: Low-content La modified symbiotic SAPO-5 / SAPO-34 composite molecular sieve

[0064] 12 grams of pseudo-boehmite and 30.0 grams of deionized water are mixed and stirred to form an aluminum source solution, and 20 grams of phosphoric acid with a concentration of 85% by weight are mixed and stirred with 30.0 grams of deionized water to form a phosphorus source solution. The concentration of 2.5 grams is 40% by weight of silica sol and 4.5 grams of deionized water were mixed and stirred to form a silicon source solution.

[0065] Then, the phosphorus source solution is slowly added dropwise to the aluminum source solution to form a mixed solution of the aluminum source and the phosphorus source, stirred evenly for 1 hour, then the silicon source solution is added to the mixed solution of the aluminum source and the phosphorus source, and stirred evenly for 1 hour Hour, form the mixed solution of silicon source, aluminum source and phosphorus source, continue t...

Embodiment 3

[0068] Example 3: The SAPO-5 / SAPO-34 composite molecular sieve modified by medium content La

[0069] 12 grams of pseudo-boehmite and 30.0 grams of deionized water are mixed and stirred to form an aluminum source solution, and 20 grams of phosphoric acid with a concentration of 85% by weight are mixed and stirred with 30.0 grams of deionized water to form a phosphorus source solution. The concentration of 2.5 grams is 40% by weight of silica sol and 4.5 grams of deionized water were mixed and stirred to form a silicon source solution.

[0070] Then, the phosphorus source solution is slowly added dropwise to the aluminum source solution to form a mixed solution of the aluminum source and the phosphorus source, stirred evenly for 1 hour, then the silicon source solution is added to the mixed solution of the aluminum source and the phosphorus source, and stirred evenly for 1 hour Hour, form the mixed solution of silicon source, aluminum source and phosphorus source, continue to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com