Large-caliber packaging tin manufacturing method and product thereof

A packaging can and large-caliber technology, which is applied in the field of large-caliber packaging can preparation methods and its products, can solve the problems of complex processing procedures for three-piece cans, inability to guarantee product performance, oxidation and blackening of weld seams, etc., and achieve environmental benefits Effects of protection, expansion of packaging range, and improvement of surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

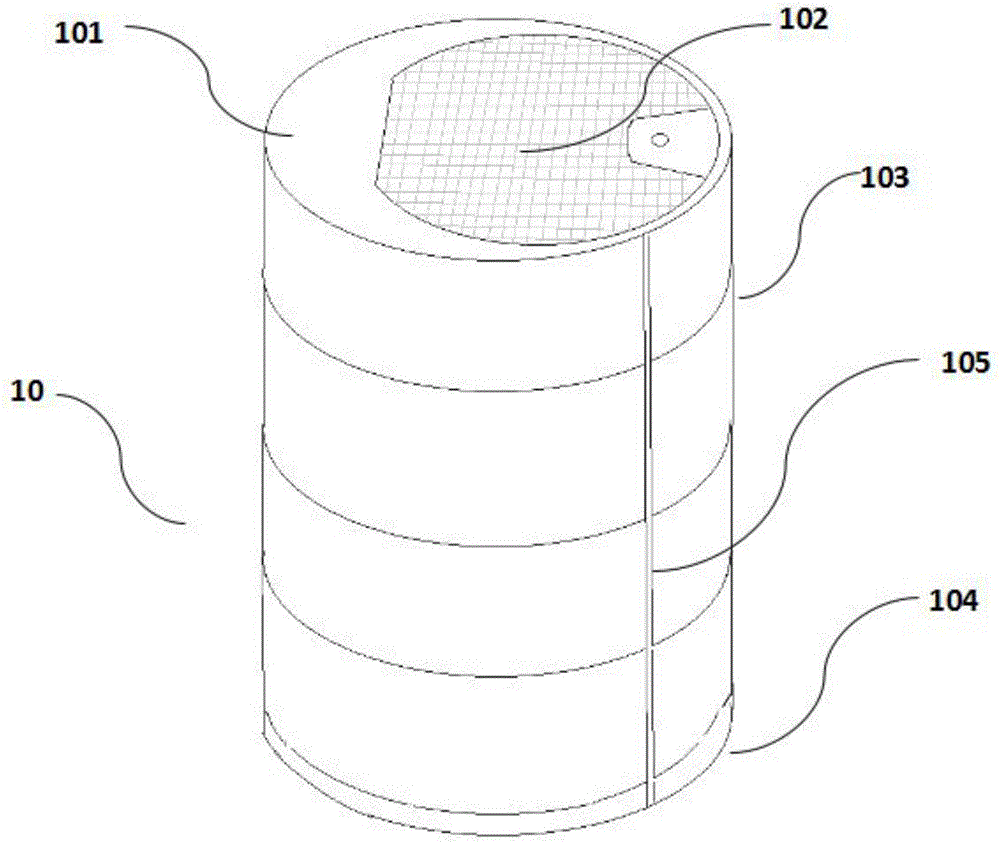

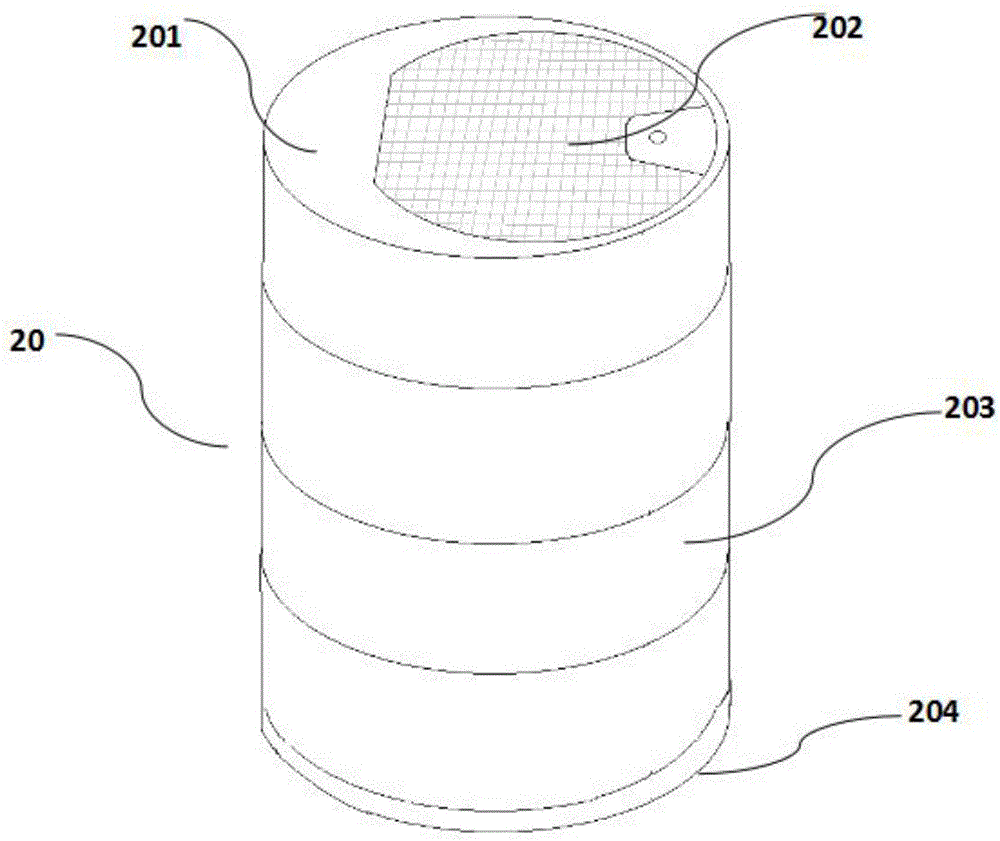

[0036] Please refer to Figure 2-4 , a method for preparing a large-diameter packaging tank, comprising the following steps:

[0037] (1) Prepare aluminum foil and some metal plates with a thickness of 0.19-0.35mm;

[0038](2) The first deformation forming: put a metal plate on the feeding table of the servo motor transmission device, and send the metal plate to the punching mold through the servo motor transmission device, and use the punching mold to open at 90T The blanking punching and forming operation is carried out on the material punching device, and the punching strength is 600-1000 kN. Among them, taking the tinplate plate with a thickness of 0.21 mm and a slit diameter of 320 mm as an example, the punching strength is 688 kN. Take tinplate sheet with 0.23mm and slit diameter of 470mm as an example, the stamping strength is 882 kN; the main motor of the 90T blanking and punching device rotates at a speed of 50-150R / min, and punches and cuts the tinplate sheet throug...

Embodiment 2

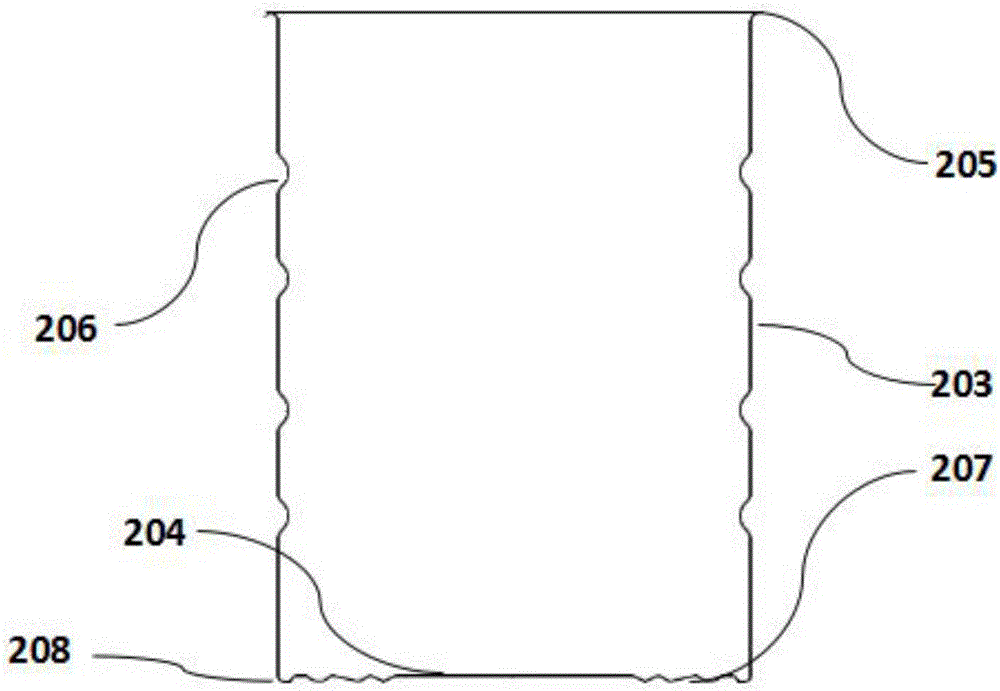

[0052] The main difference between this embodiment and Embodiment 1 is that the step (5) also includes the following steps: placing the secondary molding semi-finished product on the rolling mold to perform rolling treatment, and forming several rolling ribs on the secondary molding semi-finished product 206. Other steps are the same as those in Embodiment 1, and will not be repeated here.

[0053] The rib rolling treatment step in this embodiment can better strengthen the strength of the can body. The rolling ribs can be one or more, which is determined according to the height of the packaging tank, the composition and characteristics of the packaged items.

Embodiment 3

[0055] Please refer to Figure 5 , the main difference between this embodiment and Embodiment 2 is that the step (5) also includes the following steps: placing the secondary molding semi-finished product after the rolling process on the necking mold for necking treatment, forming a neck with a diameter of 83-127mm, secondary molded semi-finished products with a tank neck 511 height of 30-80mm. The flanging processing method in this step is: die punching and flanging are adopted. Other steps are the same as those in Embodiment 2, and will not be repeated here.

[0056] The purpose of the necking treatment step in this embodiment is to match the size of the neck opening of the can neck 511 with the size of the top cover 501 and the aluminum foil 502 , so as to reduce the size of the tin plate required for the packaging can 50 as a whole.

[0057] What needs to be explained here is that the rolling processing steps of embodiment two and the necking processing steps of embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com