Blank manufacturing method of tractor transmission

A manufacturing method and gearbox technology, applied in manufacturing tools, molding machines, casting and molding equipment, etc., can solve problems such as high requirements for workers' skilled operation skills, uncertain dimensions of blanks, and large labor workload for workers, reducing machinery and equipment. The effect of processing volume, realizing automatic production and reducing casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

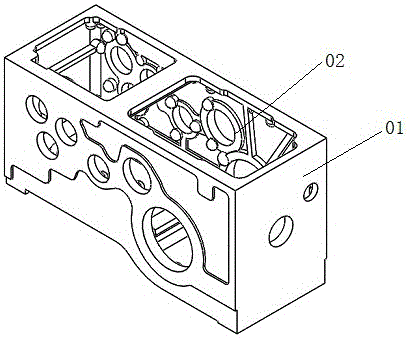

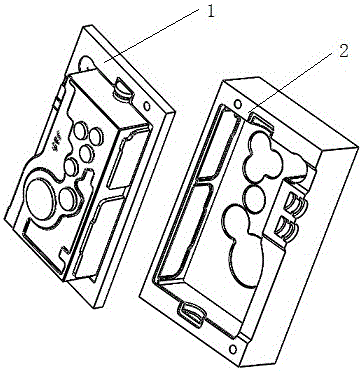

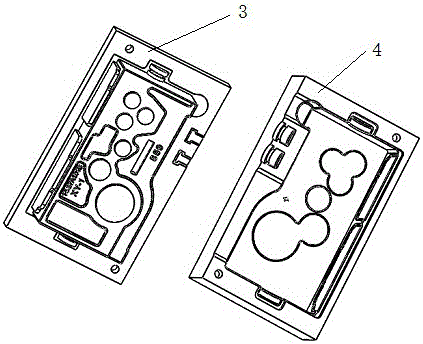

[0050] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as Figure 1 to Figure 13 , according to the design drawing of the tractor gearbox, in this example, a medium-sized tractor gearbox is taken as an example, the tractor gearbox is divided into upper part and lower part, and the external dimension of the tractor gearbox is enlarged by 8-12mm, and the upper part of the tractor gearbox is made respectively The shell mold and the upper sand shell mold 1 of the lower sand shell mold, the lower mold 2 of the upper sand shell, the upper mold 3 of the lower sand shell, and the lower mold 4 of the lower sand shell, and are respectively made into the upper sand shell of the tractor gearbox and the tractor gearbox The lower sand shell; the upper sand shell of the tractor gearbox and the lower sand shell of the tractor gearbox are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com