A fully automatic laser etching machine

A laser etching, fully automatic technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of complex process, inability to achieve mass production, low efficiency, etc., to improve work efficiency, realize intelligent control, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

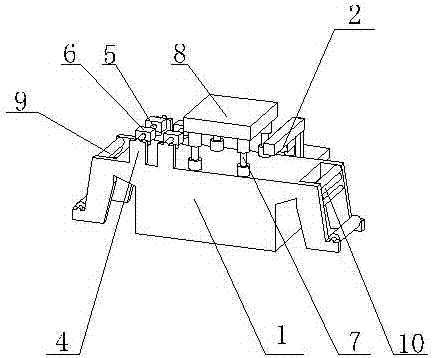

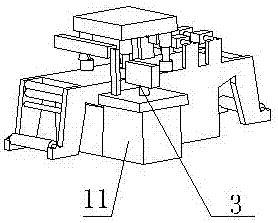

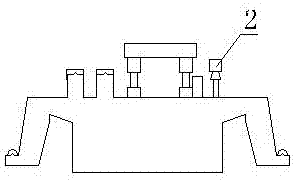

[0017] Embodiment: A fully automatic laser etching machine, comprising a frame 1, a transmission device, an ultraviolet laser emitting device 2, a host computer 3, and an edge correction and tracking device, the transmission device and the ultraviolet laser emitting device 2 are all located on the frame 1, the transmission device is used for the transmission of the label, the ultraviolet laser emitting device 2 is used for the etching of the label, and the host computer 3 is connected to the ultraviolet laser emitting device 2 and the transmission device for controlling the operation of both . The edge correcting and tracking device is located between the transmission device and the ultraviolet laser emitting device 2, and the edge correcting and tracking device is composed of a support 4, a track bar 5 positioned on the support 4, and three infrared sensors 6. The infrared sensor 6 is socketed with the track rod 5, and the two form a sliding fit. There are regular light-sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com