Operation station with rotary supporting system

A technology of rotating support and operation station, applied in the field of machine tool operation station, can solve the problems of single fixing method, self-evident machine tool, affecting processing efficiency, etc., to achieve the effect of easy orientation adjustment, good support effect, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

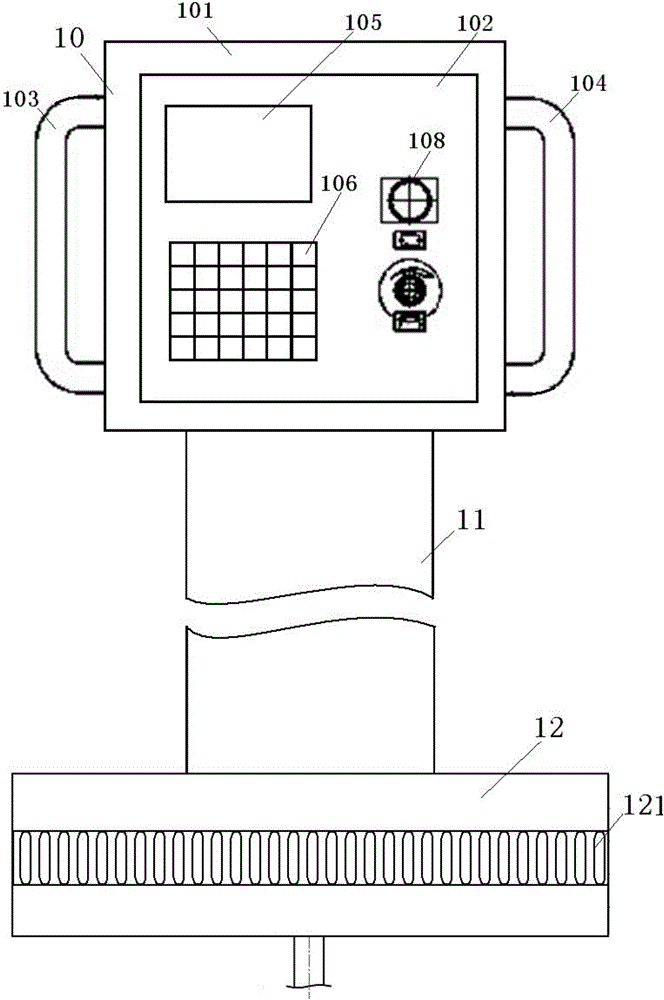

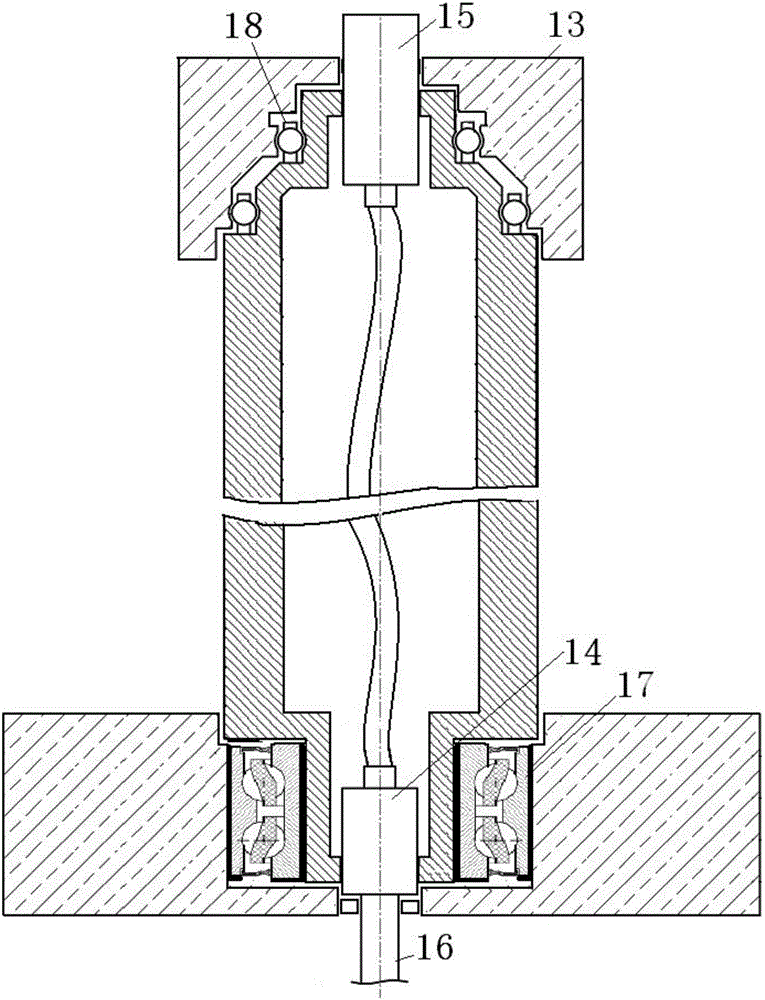

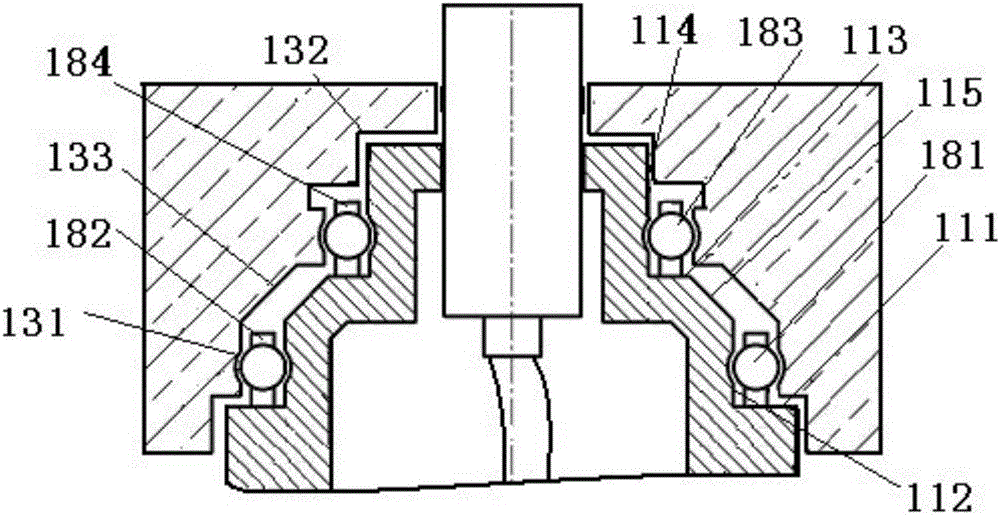

[0025] see figure 1 and 2 , shows an operator station with a rotating support system according to the invention.

[0026] The described operating station with rotating support system includes an operating station host 10 and rotating supporting system, see figure 1 , the operation station host 10 includes a square host body 101, the host body 101 is built with an operating system, its front surface is provided with an operation panel 102, and the left and right sides of the host body 101 are respectively provided with a left handrail 103 and a right handrail. Handrail 104, so that the operator holds and operates, and the operation panel 102 is embedded with a display screen 105, a plurality of operation buttons 106 and at least one indicator light 107, and the display screen 105, a plurality of operation buttons 106 and at least one The indicator light 107 is connected to the operating system to provide real-time information display, data transmission and parameter setting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com