Automatic coiled material coiling deviation correcting control system and method

An automatic deviation correction and control system technology, applied in general control systems, control/adjustment systems, winding strips, etc., can solve the problems of control accuracy impact, high system cost, fast response of electro-hydraulic servo control, etc., and achieve response speed And steady-state control precision is small, the detection precision is high, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

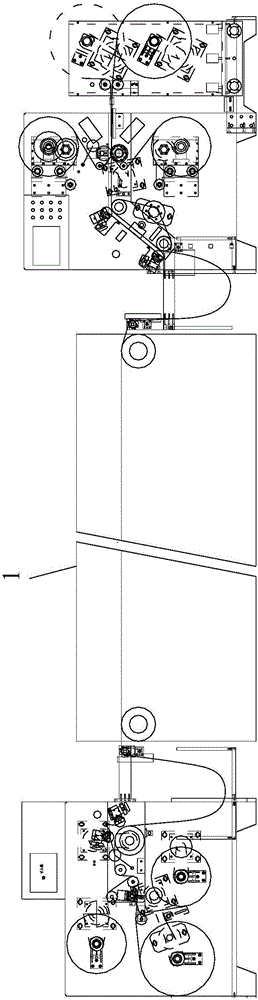

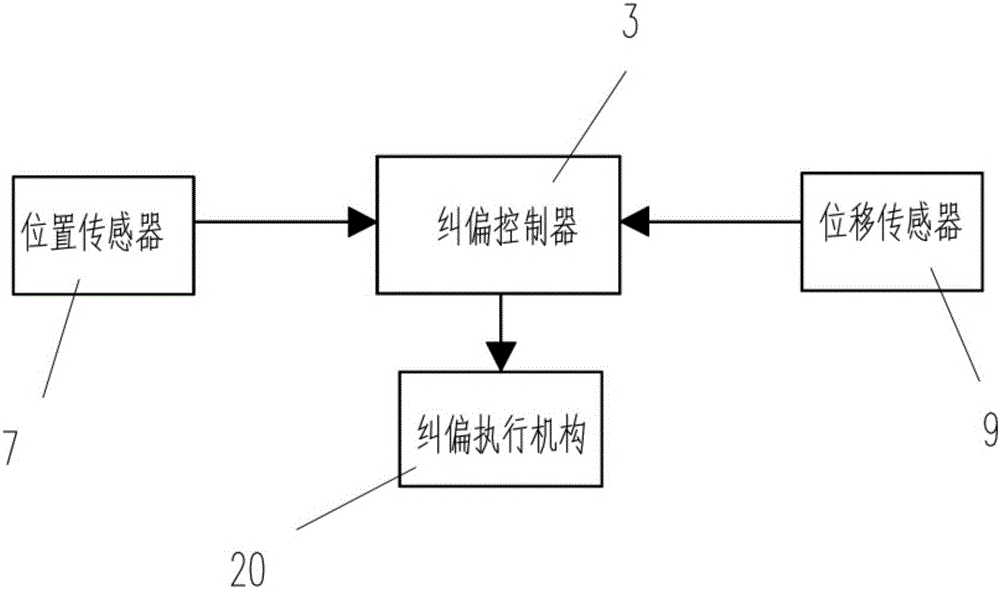

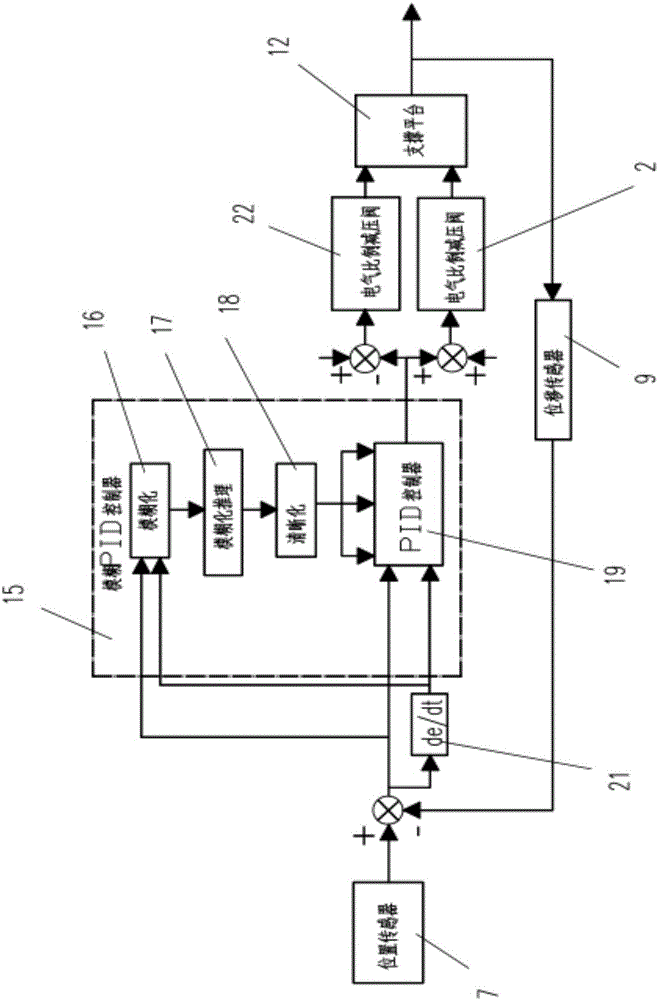

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , the present invention provides a coil winding automatic deviation correction control system comprising a frame 1, the frame 1 is provided with a position sensor 7 for detecting the edge position of the coil and a displacement sensor 9 for detecting the displacement of the support platform 12, the position sensor 7. The output signal of the displacement sensor 9 is connected to the deviation correction controller 3, and the output control signal of the deviation correction controller 3 is connected to the deviation correction actuator 20. The deviation correction actuator 20 includes a support platform 12, and the deviation correction actuator 20 is pneumatically adjusted. The mechanism realizes deviation correction by adjusting the left and right positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com