A kind of preparation method of high specific surface area magnesium hydroxide/graphene composite material

A high specific surface area, magnesium hydroxide technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of easy adsorption of impurities in filtration and washing, failure to realize industrial scale application, and affect the application of magnesium hydroxide, etc. control, mild conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

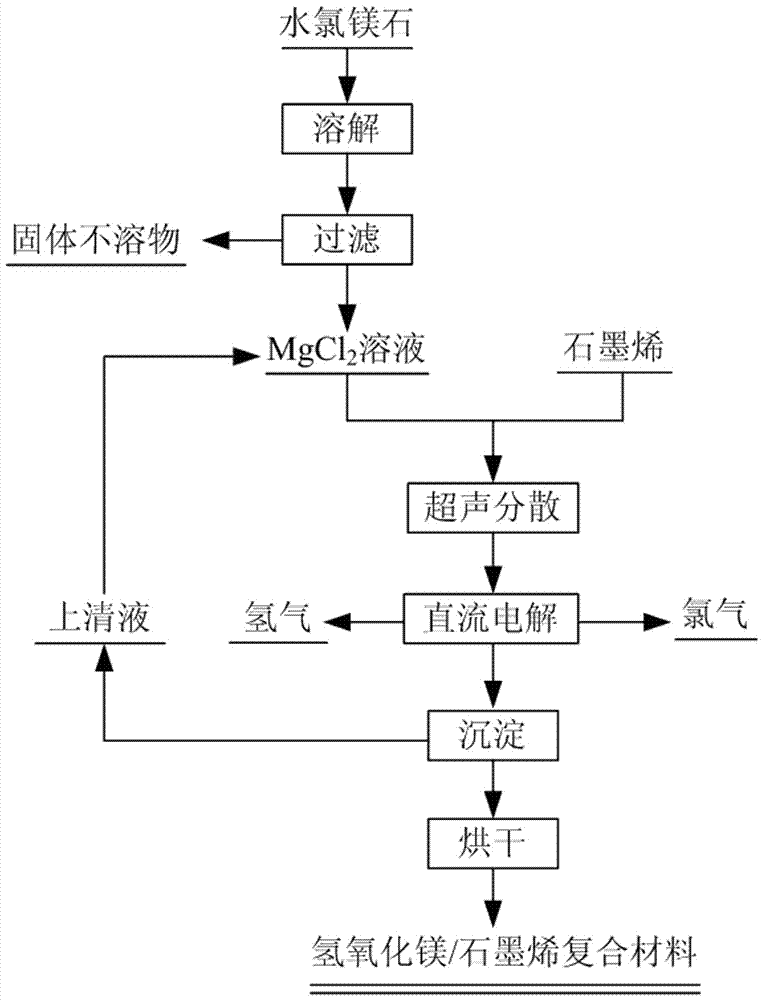

[0042] Dissolve bischofite with deionized water, filter out solid insolubles, and make MgCl 2 Mass concentration is 3% magnesium chloride aqueous solution;

[0043] Add graphene to the magnesium chloride aqueous solution, graphene accounts for 0.01% of the total mass of the magnesium chloride aqueous solution, then ultrasonically disperse for 1min, and the ultrasonic frequency is 100MHz to obtain the magnesium chloride / graphene electrolyte;

[0044] Adjust the pH value to 2;

[0045]The magnesium chloride / graphene electrolyte after adjusting the pH value is introduced into the electrolytic cell, the graphite plate is used as the cathode, and the metal or metal alloy material is used as the anode, and the magnesium chloride / graphene electrolyte is electrolyzed by direct current. The electrolysis temperature is 20°C, and the current density is 1.0A / cm 2 , the product generated by electrolysis enters the product collection chamber below the cathode, and the gas generated by ele...

Embodiment 2

[0049] Method is with embodiment 1, and difference is:

[0050] (1) Magnesium chloride aqueous solution MgCl 2 The mass concentration is 30%;

[0051] (2) Graphene accounts for 10% of the total mass of the magnesium chloride aqueous solution, ultrasonically dispersed for 120min, and the ultrasonic frequency is 20MHz;

[0052] (3) Adjust the pH value to 10;

[0053] (4) The electrolysis temperature is 80°C, and the current density is 0.05A / cm 2 ;

[0054] (5) Dry at 250°C for 60 minutes to obtain a high specific surface area magnesium hydroxide / graphene composite material with a specific surface area of 340m 2 / g;

[0055] (6) Take out the products generated by electrolysis with a colander every 600 minutes; and add magnesium chloride / graphene aqueous solution into the electrolytic cell every 600 minutes.

Embodiment 3

[0057] Method is with embodiment 1, and difference is:

[0058] (1) Magnesium chloride aqueous solution MgCl 2 The mass concentration is 20%;

[0059] (2) Graphene accounts for 5% of the total mass of the magnesium chloride aqueous solution, ultrasonically dispersed for 60 minutes, and the ultrasonic frequency is 20MHz;

[0060] (3) Adjust the pH value to 8;

[0061] (4) The electrolysis temperature is 50°C, and the current density is 0.2A / cm 2 ;

[0062] (5) Dry at 150°C for 240 minutes to obtain a high specific surface area magnesium hydroxide / graphene composite material with a specific surface area of 400m 2 / g;

[0063] (6) Take out the products generated by electrolysis with a colander every 300 minutes; and add magnesium chloride / graphene aqueous solution into the electrolytic cell every 300 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap