Production technology for anti-counterfeit label paper

An anti-counterfeiting label and production process technology, applied in the field of production technology of anti-counterfeiting label paper, can solve the problems of increased total thickness, easy damage of label paper, inability to meet high temperature requirements, etc., and achieves good wet strength and delamination resistance, good surface Effects of flatness and printability, excellent tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

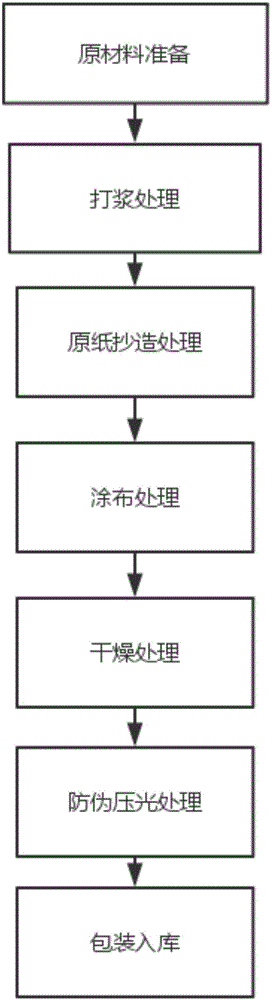

[0021] Such as figure 1 As shown, a kind of anti-counterfeiting label paper production process of the present embodiment is characterized in that, comprises following process step:

[0022] (1) Raw material preparation: The raw materials for the production of the anti-counterfeiting label paper include the following mass fractions: 50 parts of long-fiber wood pulp, 35 parts of short-fiber wood pulp, 1.5 parts of wet strength agent, 40 parts of coated latex, and 2 parts of sizing agent , 0.3 parts of retention aid, 8 parts of metallized paper, wherein the wet strength agent is specifically polyester, the sizing agent is specifically alkene-based succinic anhydride, the retention aid is specifically silica gel, and the coating latex is specifically is propionate;

[0023] (2) beating treatment: long-fiber wood pulp and short-fiber wood pulp are added to the pulper for crushing treatment and then pumped into the pulper for beating. The degree of beating is 20SR, and the beating ...

Embodiment 2

[0029] Embodiment 2: all the other are identical with embodiment 1, and difference is that beating degree is 25SR in described step (2), and beating concentration is 5%, and drying temperature is 110 ℃ in described step (3), and calender roll surface The temperature is 120°C, the coating concentration in the step (4) is 25%, the drying temperature in the step (5) is 120°C, and the drying time is 35min, and the anti-counterfeiting calendering pressure in the step (6) 400kN / m 2 , after calendering, color printing is carried out on it, wherein the calendering time is 1.2h, and the roller surface temperature is 150°C.

Embodiment 3

[0030] Embodiment 3: all the other are identical with embodiment 1, and difference is that beating degree is 30SR in described step (2), and beating concentration is 5%, and drying temperature is 110 ℃ in described step (3), and calender roll surface The temperature is 150°C, the coating concentration in the step (4) is 30%, the drying temperature in the step (5) is 130°C, and the drying time is 40min, and the anti-counterfeiting calendering pressure in the step (6) 400kN / m 2 , after calendering, color printing is carried out on it, wherein the calendering time is 1.5h, and the roller surface temperature is 180°C.

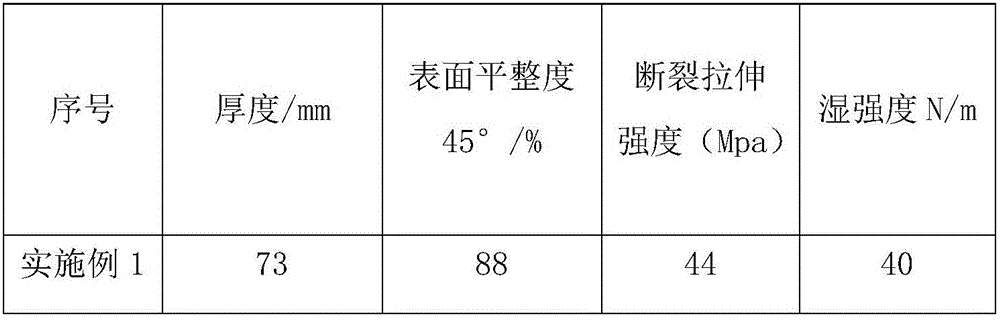

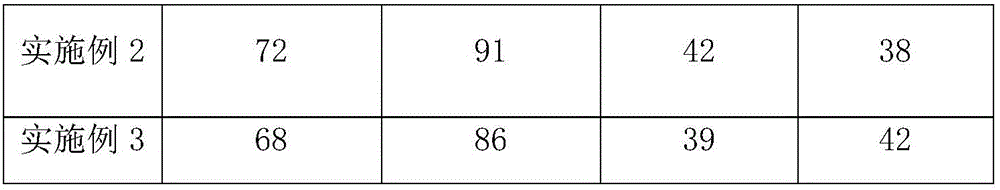

[0031] After the above process steps, the PE heat shrinkable film sample was taken out, and the following data were obtained:

[0032]

[0033]

[0034] It can be seen from the above data that the product obtained by the present invention has good wet strength, and through reasonable manufacturing process and materials, it has excellent tear resistance, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com