Arched base pavement structure

A technology of pavement structure and base layer, applied in the direction of roads, roads, buildings, etc., can solve the problems of high construction technology level and high cost, and achieve the effect of facilitating later maintenance, repair and replacement, convenient construction, and eliminating fatigue damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

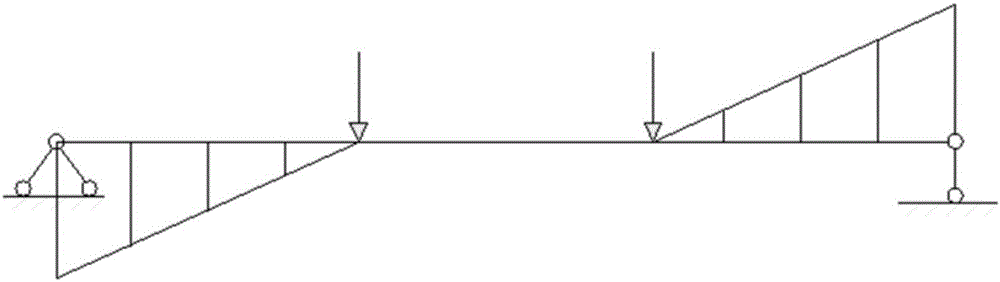

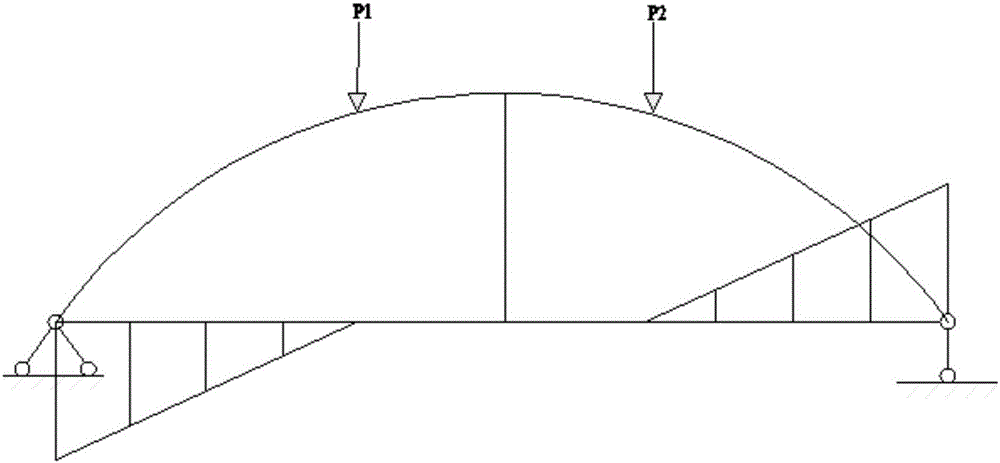

Embodiment 1

[0035] As the junction of rigid abutment and flexible embankment, the transitional section of the road and bridge is prone to uneven settlement. The main difference is that the abutment at the lower part of the bridge is rigidly supported with little deformation, while the soil base 1 support of the road is flexible. Arch base 4 structure described in the present invention, as Figure 6 As shown, according to the calculation of road mechanics and the actual situation on site, the ratio of H / L is adjusted to gradually change the stiffness of the transition section of the road and bridge, thereby minimizing the settlement difference between the road and bridge. Layer 6cm medium-grained asphalt concrete + 8cm coarse-grained asphalt concrete + 2cm asphalt fiber seal + vault 15cm, arch foot 40cm lean concrete + 5% cement stabilized macadam + soil base 1. Use the present invention in such special sections as the road-bridge transition section, if the distance is shorter than 6m or t...

Embodiment 2

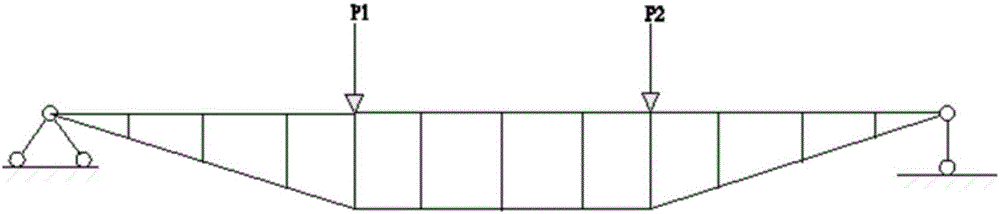

[0037] In the application of road sections with poor ground conditions such as soft ground and broken ground, when the ground conditions are poor and difficult to handle, as the aforementioned principle of strengthening the support member 8 is known, this can effectively prevent uneven settlement and weaken uneven or relatively The impact of the soil base 1 on the stability and bearing capacity of the upper structure, but considering the economy and the effectiveness of the support, strengthening support members 8 can be set at the bottom of the base 4 at regular intervals.

Embodiment 3

[0039] In the application of urban roads with many pipes and line segments, when municipal roads, the drainage pipe E is not used for drainage, but it is used to bury urban pipelines to prevent excessive pipelines and lines from affecting the city appearance. At the same time, the drainage pipe itself can be waterproof, and the drainage gravel cushion is used around the drainage pipe to prevent the groundwater from affecting the upper structure. It can also concentrate the upper part of the seepage, and then discharge the arched subgrade through the drainage ditch, so as not to affect the normal use of the road structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com