Operation device related to digging pile mechanical hole forming and construction method of operation device

A technology of mechanical hole forming and construction method, which is applied in drilling equipment and methods, sheet pile walls, earthwork drilling, etc. Safety, reduce labor intensity, and solve the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

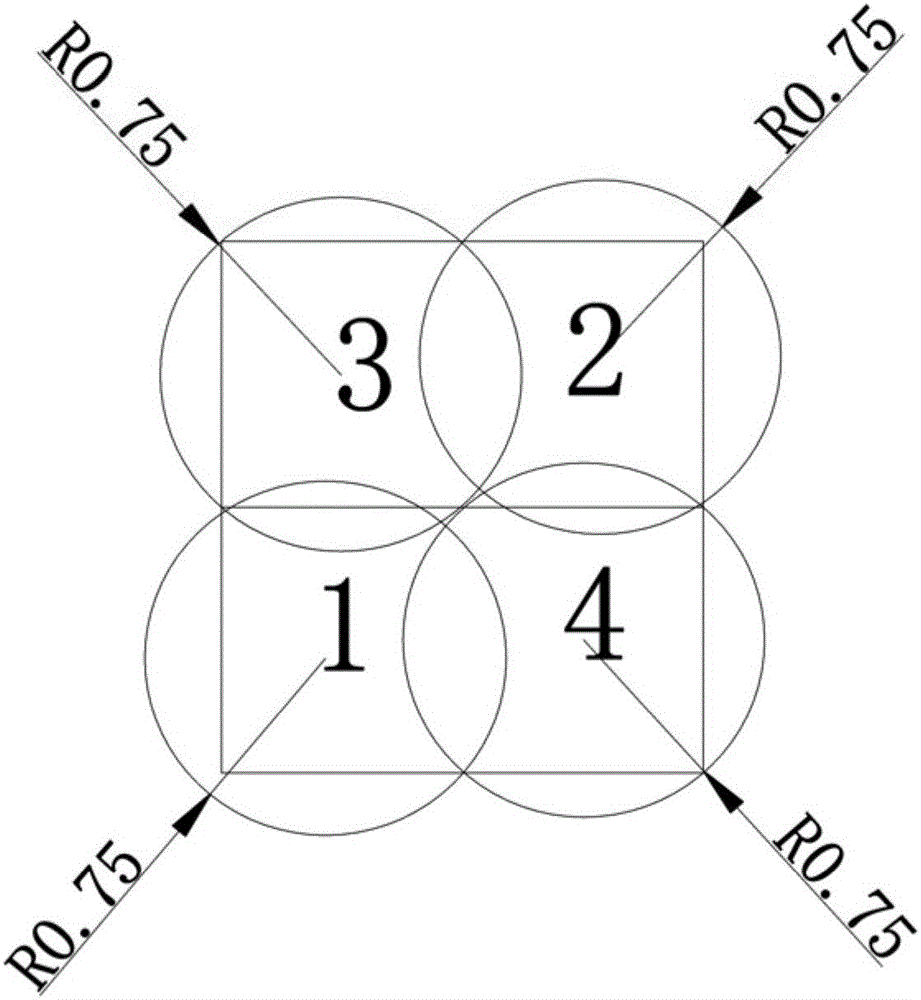

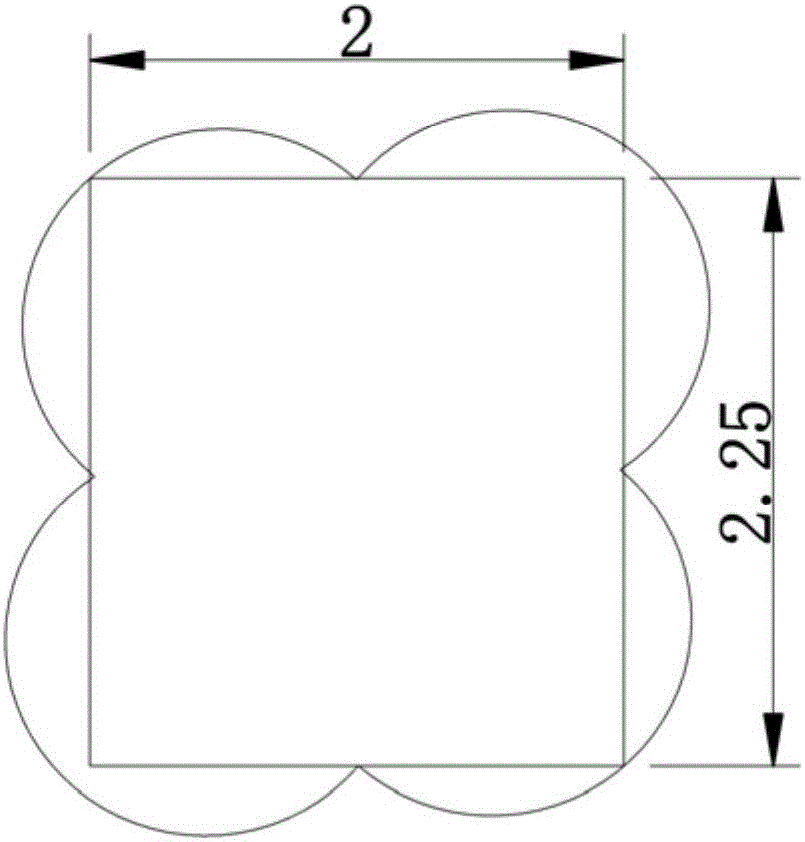

[0027] The rotary drilling rig in the present invention generally adopts a round drill bit, and replaces a rectangular shape with a combination of round drill bits with different diameters, thereby replacing artificial holes, and is suitable for rocky areas. Its construction steps are as follows:

[0028] 1. Point stake out

[0029] Use the total station to accurately determine the four corners of the excavated piles and the centers corresponding to different circles, and protect the piles to ensure that the piles can be restored.

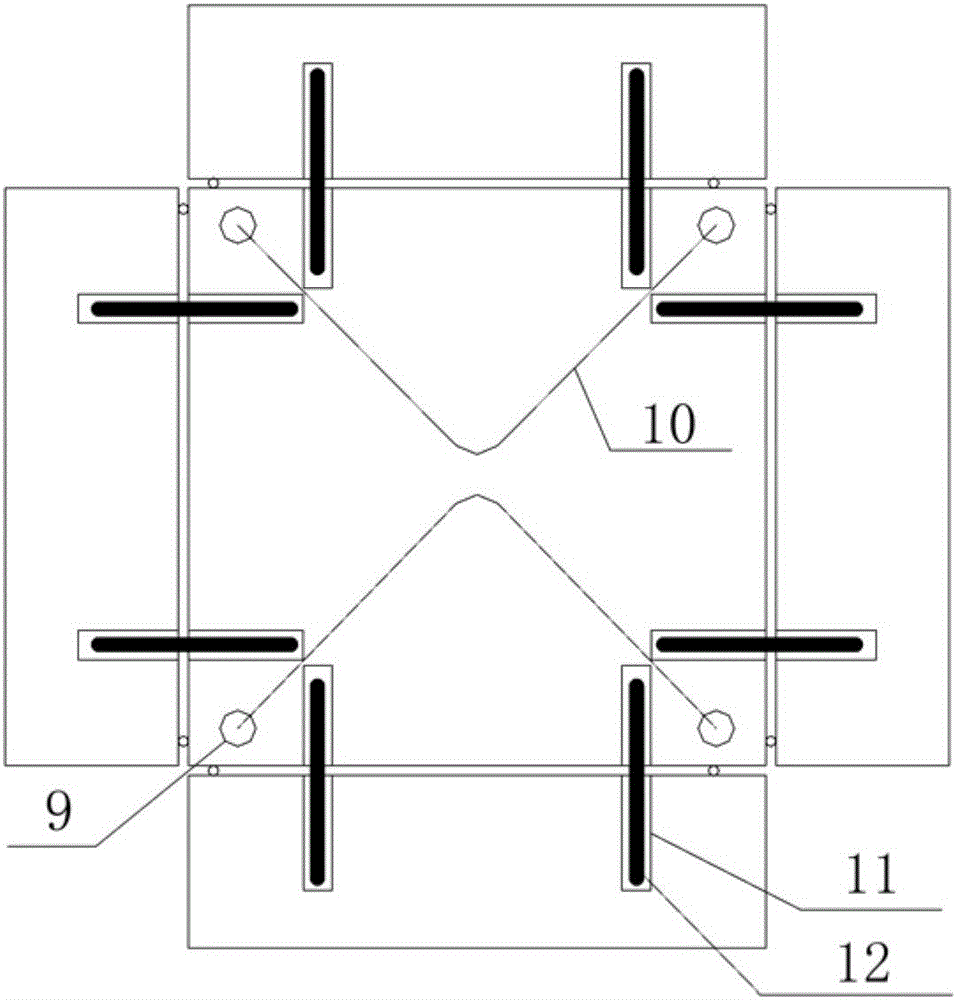

[0030] 2. Lock construction

[0031] In order to ensure the safety of the pile during the entire con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com