Rotor engine and working method thereof

A rotor engine and rotor technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of low engine thermal efficiency, affecting machine work, and inability to do work effectively, achieving long combustion time, reducing harmful gas emissions, The effect of low mechanical strength requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further explained below in conjunction with the accompanying drawings.

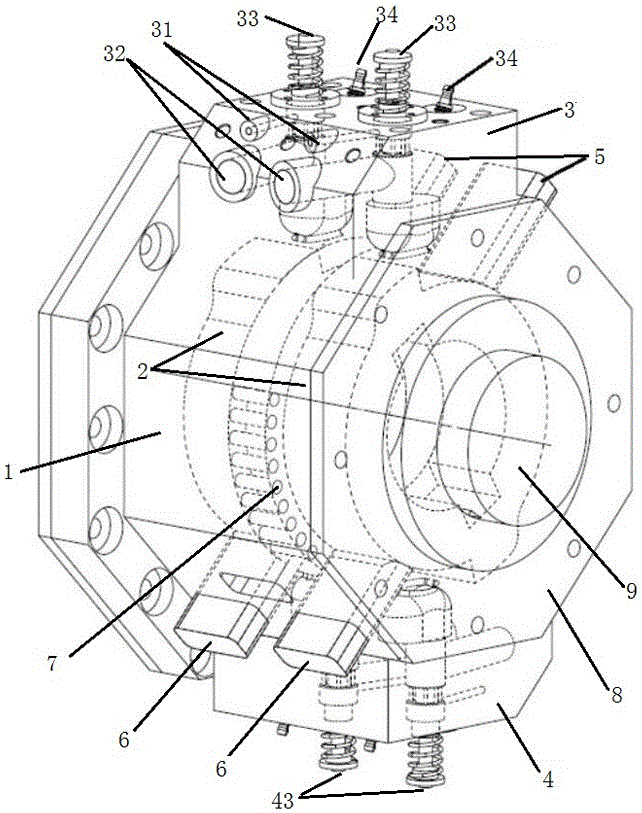

[0045] Such as Figure 3 to Figure 5 As shown, a rotary engine includes a set of power modules for outputting power. The power modules include a casing 1, an end cover 8, two cylinder heads installed on the casing 1, and two rotor units. The above-mentioned two cylinder heads are symmetrically distributed at the upper and lower positions of the casing 1, that is, the upper cylinder head 3 and the lower cylinder head 4 in the figure, and the N rotor units are arranged in the casing 1 sequentially. A baffle is arranged between adjacent rotor units, and a plurality of small holes 7 for passing air between the rotor units are arranged on the baffle.

[0046] The above-mentioned rotor unit includes a rotor 2, the rotor 2 is circular, the outer diameter of the rotor 2 is smaller than the inner cavity diameter of the casing 1 and two protrusions are arranged symmetrically in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com