Fixing mechanisms for lead screw bearings

A fixed mechanism and fixed structure technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems that affect transmission and positioning accuracy, screw rod elongation, easy sagging, etc., to avoid string movement and bending, and facilitate loading and unloading , the obvious effect of supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

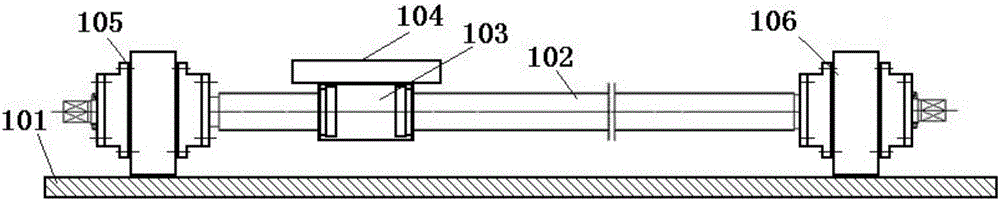

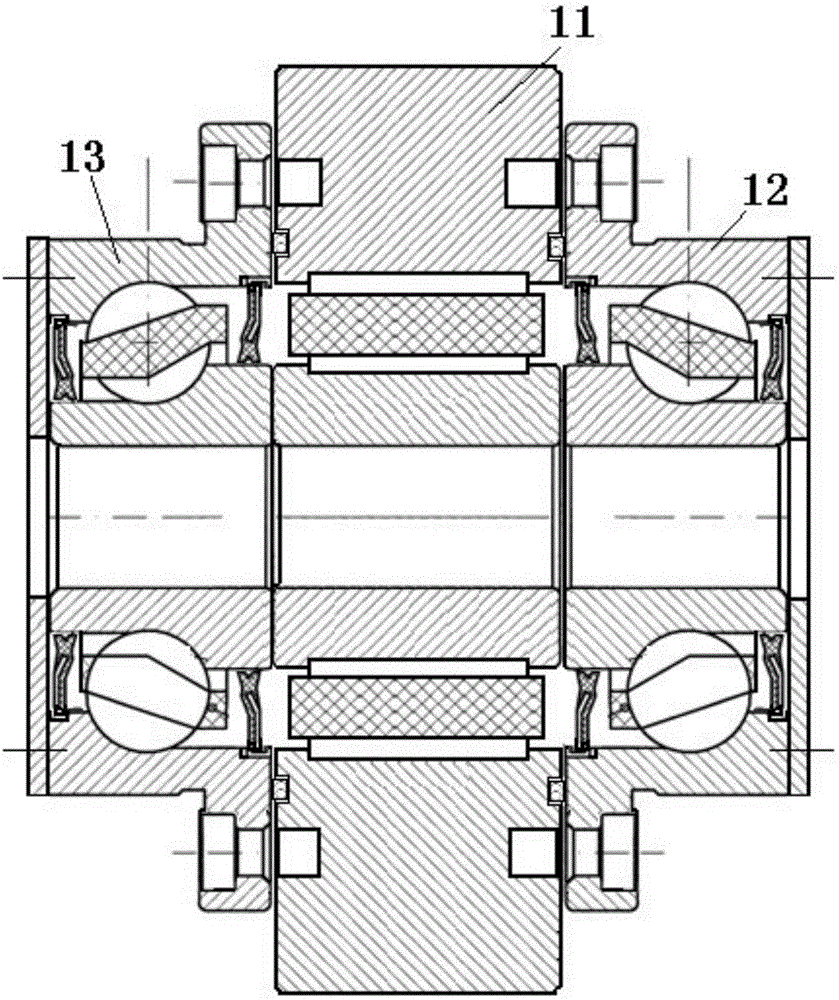

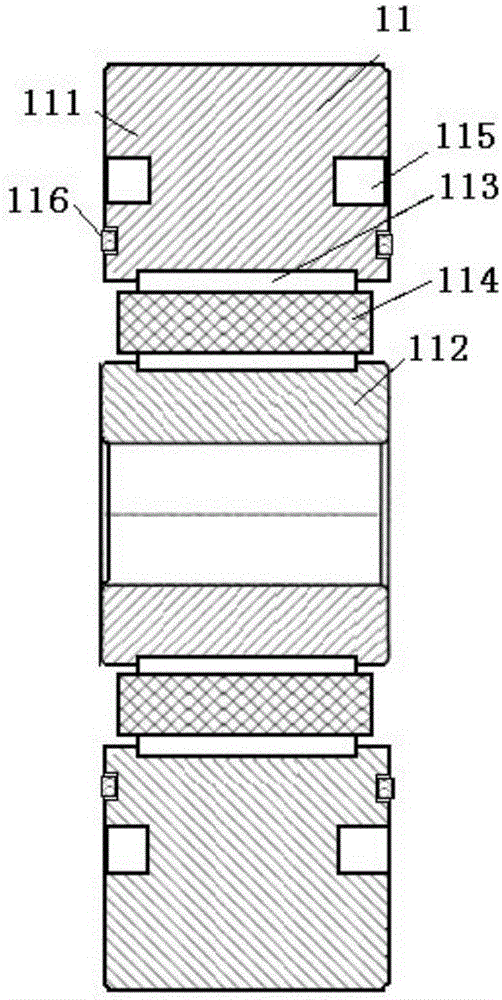

[0026] see Figure 1 to Figure 4 , shows the screw bearing fixing mechanism of the present invention.

[0027] The fixing mechanism for the screw bearing is applied in the screw transmission device, figure 1 The shown screw drive device includes a base 101, on which a ball screw assembly is arranged, and the ball screw assembly includes a screw 102 and a nut 103 arranged around the screw 102, and a moving platform is arranged on the nut 103 104, the mobile platform 104 can carry out linear motion in a certain direction through the guide device, so the rotary motion of the screw mandrel 102 can be converted into the linear motion of the nut 103 and the mobile platform, and the two ends of the screw mandrel 102 are respectively provided with The fixing mechanism 105 for the left bearing and the fixing mechanism 106 for the right bearing are the fixing mechanisms for the screw bearing of the present invention.

[0028] see Figure 2 to Figure 4 , which specifically shows the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com