Workshop air source pressurization and pressure stabilization system

A technology of air intake supercharging and air intake system, which is used in pipeline systems, pressure vessels, fixed-capacity gas storage tanks, etc. The effect of source pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

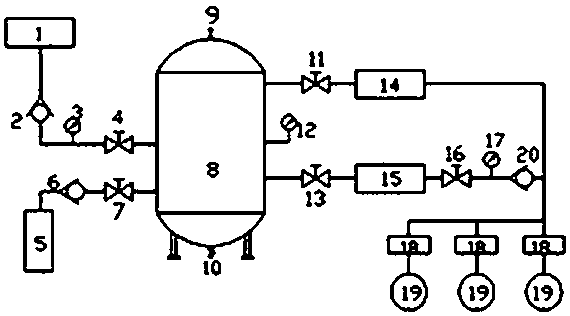

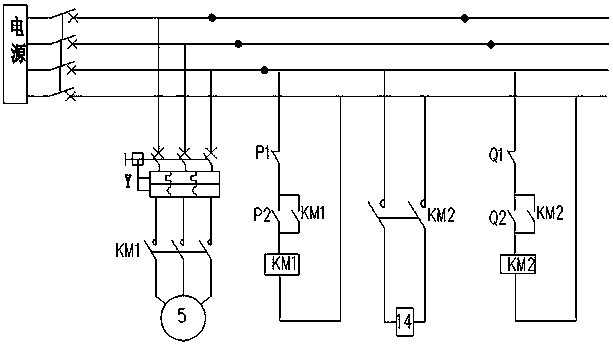

[0015] Such as figure 1 As shown, the workshop air source pressurization and stabilization system provided by the present invention includes an air intake system, an air outlet system and a pressure stabilization system. Gas pipeline and outlet pressurized pipeline, the pressure stabilizing system includes an air storage tank 8, wherein, the air intake pipeline includes a total gas station 1, an intake check valve 2, an intake pressure gauge 3 and an intake Air gate valve 4; the intake booster pipeline includes a booster air pump 5, an intake booster check valve 6 and an intake booster gate valve 7 connected in sequence, and the outlet pipeline includes a sequentially connected The first gas outlet gate valve 13, the cold dryer 15, the second gas outlet gate valve 16, the gas outlet pressure gauge 17, and the gas outlet check valve 20. The gas outlet booster pipeline includes the gas outlet booster gate valve 11, the electric control valve 14. The intake gate valve, intake bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com