Liquid quenching medium rapid cooling process and device for heat treatment

A technology of quenching medium and liquid cooling medium, applied in the field of heat treatment, can solve the problems of waste of water resources, water cooling capacity can not meet the requirements of workpiece quenching efficiency, no recycling, etc., to improve quenching efficiency, omit booster pump, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

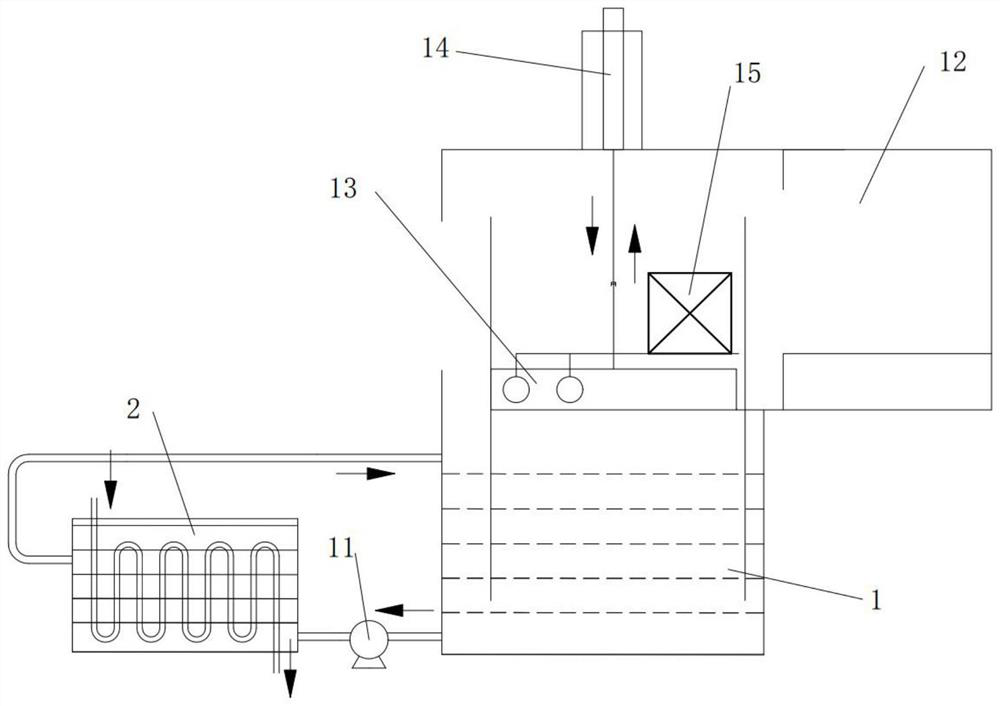

[0045] see figure 1 As shown, the present embodiment provides a quenching medium rapid cooling process for heat treatment, which is mainly used in heat treatment equipment. The effect of the cylinder 14 drops and is immersed in the quenching tank 1 for quenching and cooling. During the continuous quenching process of the workpiece 15, the temperature of the liquid quenching medium in the quenching tank 1 increases, resulting in a decrease in the quenching quality and efficiency of the workpiece 15. Therefore, it is necessary to treat the high temperature The liquid quenching medium is used for real-time cooling to meet the quenching requirements of the workpiece.

[0046] read on figure 1 As shown, this embodiment provides a rapid cooling process of quenching medium for heat treatment. The main technical solution is to make full use of the latent heat of vaporization of low-temperature liquid carbon dioxide or low-temperature liquid nitrogen to exchange heat and cool down the...

Embodiment 2

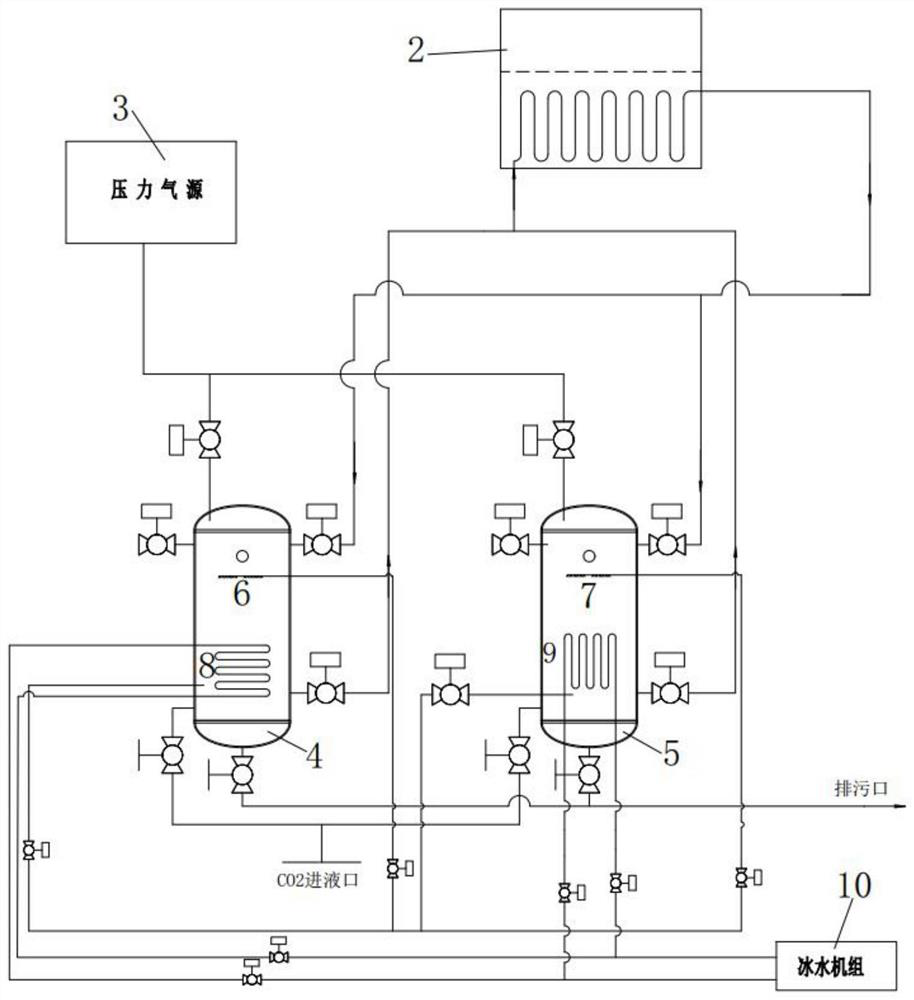

[0050] see figure 2 As shown, this embodiment provides a method for recovering and reusing the gaseous cooling medium after heat exchange, which is used in the rapid cooling process of the quenching medium for heat treatment described in Example 1, so as to make full use of the cooling effect of liquid carbon dioxide or liquid nitrogen To maximize the utilization of cooling capacity.

[0051] Such as figure 2 As shown, in this example, by CO 2 The liquid inlet is charged into the first storage tank 4 with liquid carbon dioxide in advance, and the filling amount accounts for at least 60% of the volume of the storage tank. High-pressure gas is used as the transmission power, and the high-pressure gas adopts 3.3MPa high-pressure air, and a certain pressure of high-pressure gas is passed into the first storage tank 4, and the liquid cooling medium in the first storage tank 4 is alternately pressed and sent to the quenching Cold evaporator 2. At the same time, the second stor...

Embodiment 3

[0054] see figure 2 As shown, in order to strengthen the cooling and liquefaction speed of gaseous carbon dioxide in the storage tank, this embodiment provides a method for recycling the gaseous cooling medium after heat exchange, so as to make full use of the cooling capacity of liquid carbon dioxide or liquid nitrogen to realize cooling. Maximize capacity utilization.

[0055] The difference from the above-mentioned embodiment 2 is that this embodiment uses high-pressure gas to pump the liquid cooling medium in the first storage tank 4 through the second injection mechanism 7 and spray it into the second storage tank 5, so that the first storage tank The tank 4 is a liquid storage tank, and the second storage tank 5 is used as a gas recovery tank. The gaseous cooling medium received in the second storage tank 5 is cooled and converted into a liquid cooling medium for recycling by using the principle of throttling and expansion.

[0056] In addition, a first injection mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com