Multi-chamber fluidized bed device for converting solid fuel chemistry chains

A multi-chamber fluidized bed, solid fuel technology, applied in fluidized bed combustion equipment, fuels burned in a molten state, combustion types, etc., can solve the problem of reducing heat transfer and utilization efficiency, increasing the difficulty of reactor operation, and unfavorable gasification. Reaction and other problems, to achieve the effects of convenient operation, simple structure and reasonable heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

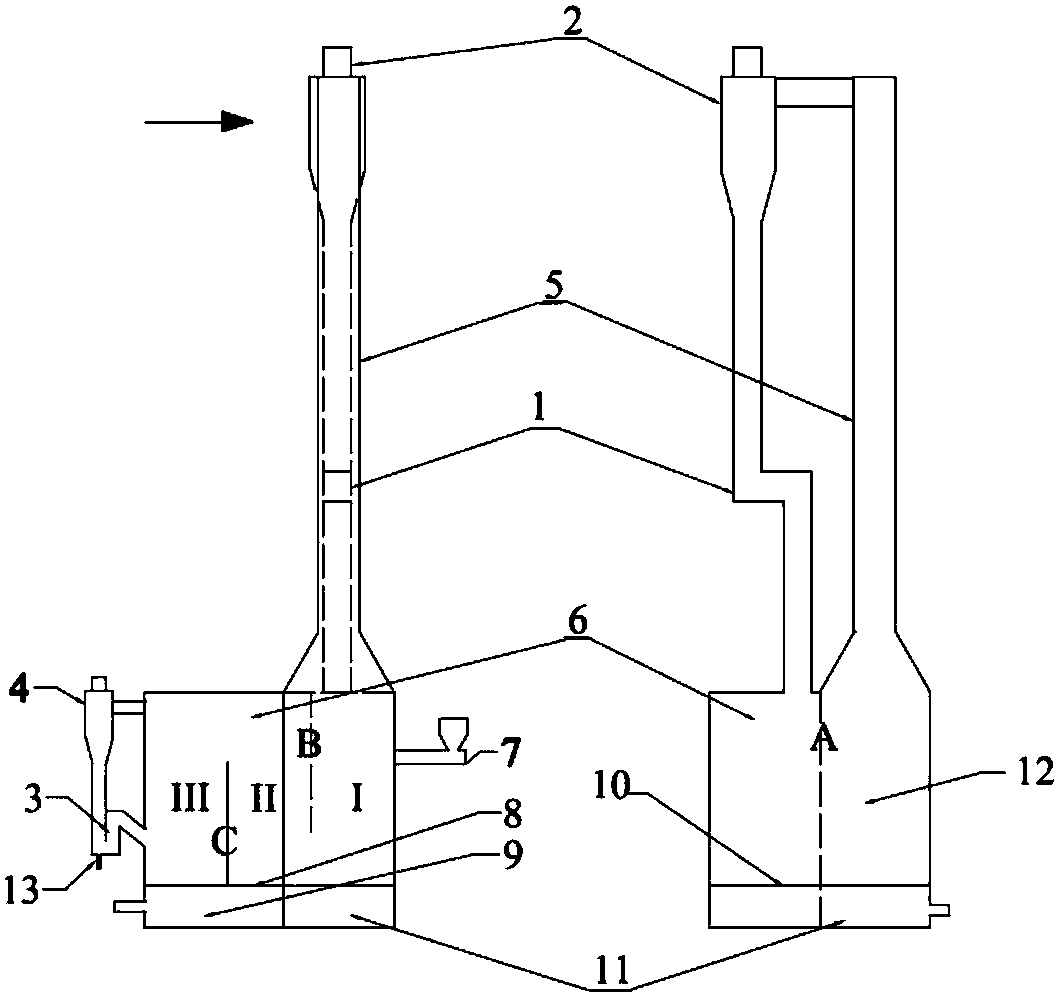

[0029] The multi-chamber fuel reactor 6 described in this embodiment is a side-by-side horizontal eye shape, and the middle is separated by two baffles. The lower end of the I chamber and the II chamber of the multi-chamber fuel reactor 6 communicates, and the upper end of the II chamber communicates with the III chamber. , when in use, water vapor is used as the fluidizing medium of the multi-chamber fuel reactor 6, and the material is CaSO 4 Oxygen Carrier and Shenmu Coal, CaSO 4 The mass ratio of carbon in Shenmu coal is 1:2, and the CaSO 4 The Heshenmu coal enters the I chamber of the multi-chamber fuel reactor 6 from the solid feeding device 7, and the carbon conversion rate is increased from 75% of the existing single-chamber fuel reactor to more than 95%.

Embodiment 2

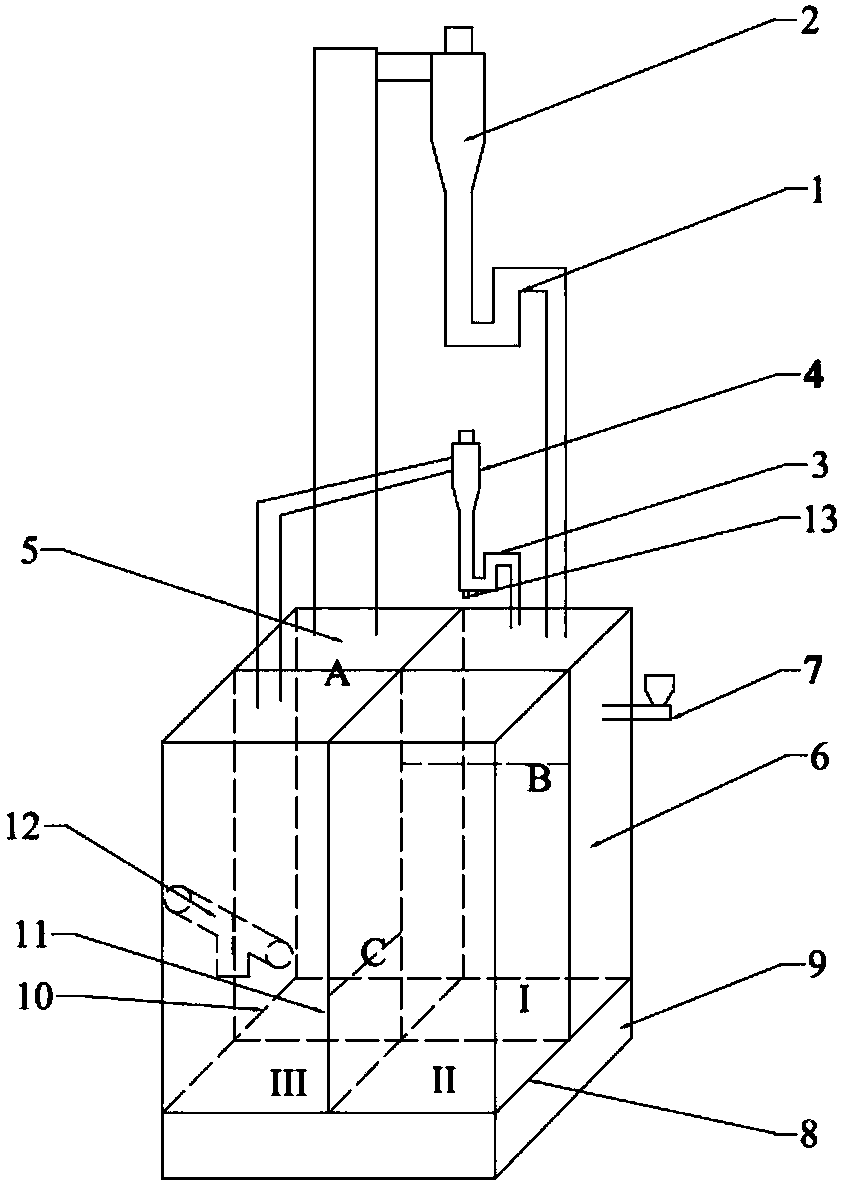

[0031] The multi-chamber fuel reactor 6 described in this embodiment is divided into a three-chamber structure by a baffle, the three chambers of the multi-chamber fuel reactor 6 and the air reactor 5 are distributed in a square shape, and the air reactor 5 and the multi-chamber fuel reactor 6 There is no communication between the I chambers, the upper end of the I chamber and the II chamber of the multi-chamber fuel reactor 6 communicates, the II chamber of the multi-chamber fuel reactor 6 communicates with the lower end of the III chamber, and the multi-chamber fuel reactor 6III chamber and the air reactor return material The device 12 is connected to each other. When in use, water vapor is used as the fluidization medium of the multi-chamber fuel reactor 6 to carry out the coal chemical loop gasification reaction, and the material is Fe 2 o 3 Oxygen carrier and Shenmu coal, the condensed gas composition obtained from the upper part of the second cyclone separator 4 is: CO=2...

Embodiment 3

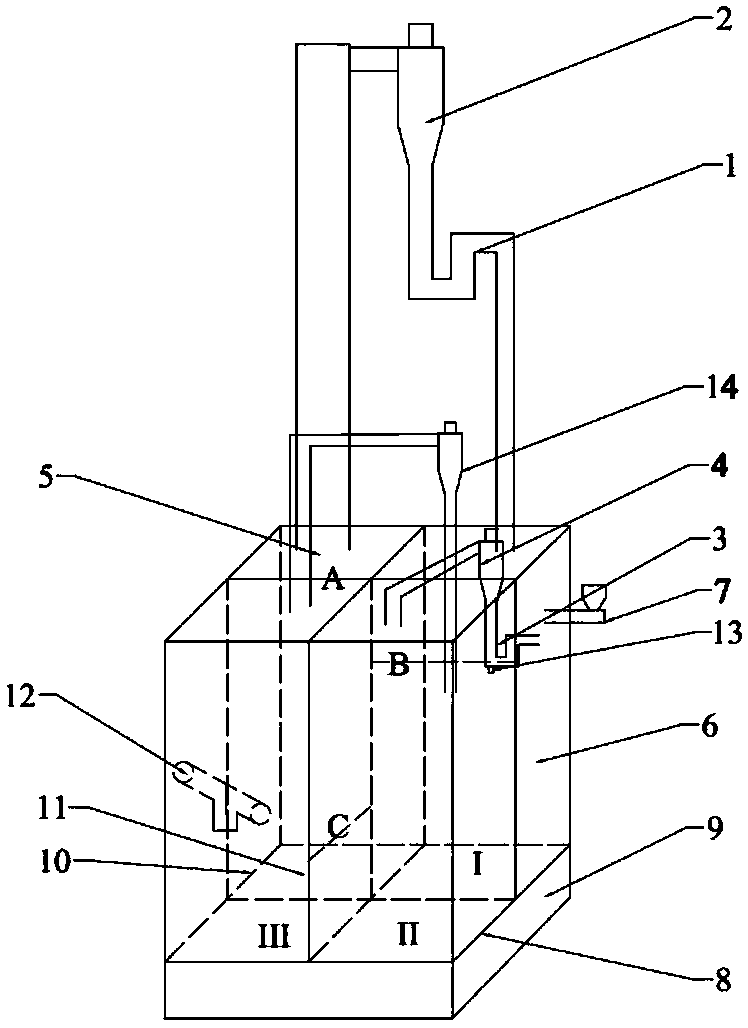

[0033] Present embodiment increases the 3rd cyclone separator 14 on the basis of embodiment 2, does not communicate between air reactor 5 and I room of multi-chamber fuel reactor 6, the I room of multi-chamber fuel reactor 6 and the upper end of II room Communication, between the II chamber and the III chamber is connected by the return device 12, the III chamber and the air reactor 24 are also connected by the return device 12, during use, the material Fe 2 o 3 Oxygen carrier, CaO and Shenmu coal enter the I chamber of the multi-chamber fuel reactor 6 from the solid feeder 7, and the water vapor enters the first gas pre-distribution chamber 9 as the fluidizing medium, and then passes through the billionth gas distribution plate 8 to make the materials Fluidization, with the fluidization of the material, the material passes through the II room and enters the III room through the return device, and the oxygen carrier and Shenmu coal are carried out in the I room and the II room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com