Smoke exhaust ventilator

A technology of range hood and fan, applied in the field of range hood, can solve the problem of high noise of range hood, and achieve the effects of eliminating vortex, reducing wind resistance and improving noise reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

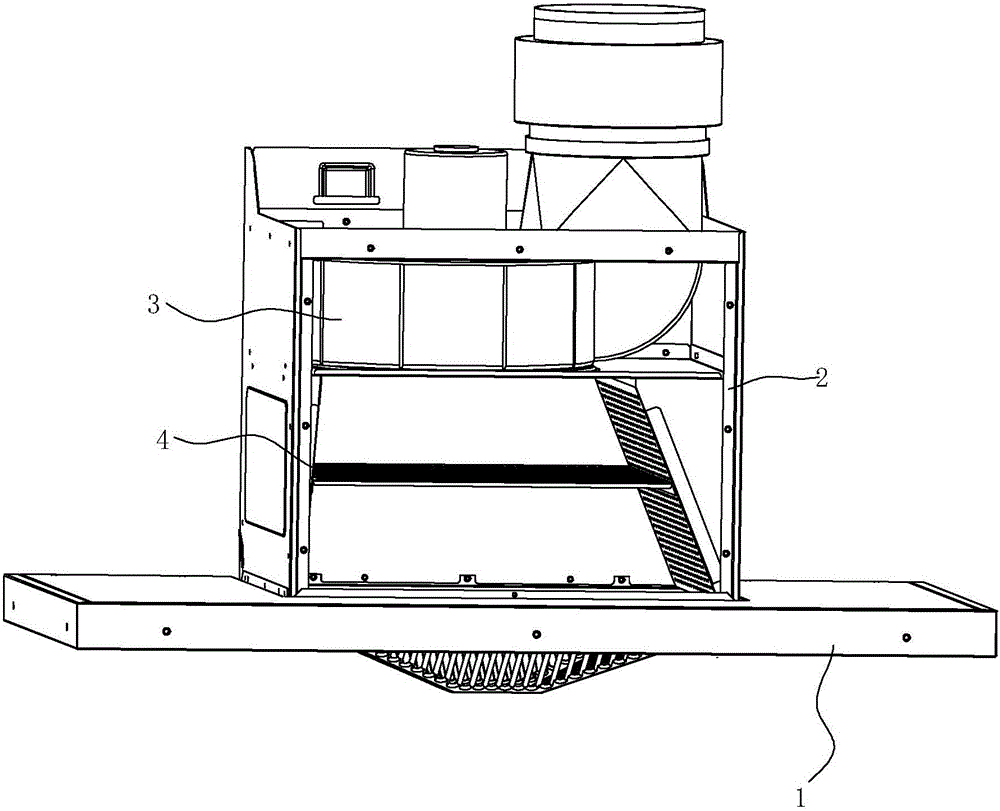

[0024] see figure 1 , a range hood, comprising a smoke collection hood 1, a box 2 arranged above the smoke collection hood 1, a fan 3 is arranged in the box 2. An air inlet is provided on the fume collecting hood 1, so that the fan 3 in the box body 2 can suck the oil fume into the box body 2 through the air inlet and discharge it to the public flue.

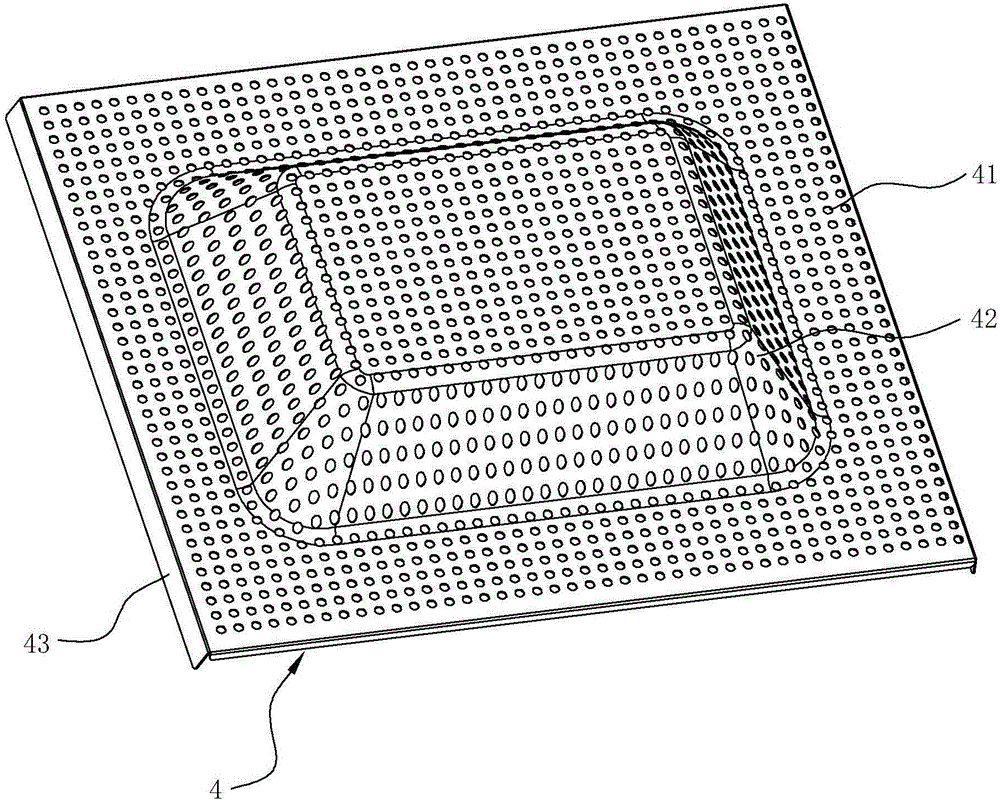

[0025] A rectifying net 4 is arranged inside the box body 2, and the rectifying net 4 is horizontally arranged in the box body 2. The rectifying net 4 is provided with mesh holes 41. By setting the rectifying net 4, the airflow entering the fan 3 can be divided, To eliminate the large vortex in the airflow, so as to achieve the purpose of reducing noise. In this embodiment, the rectifying net is not a plane, but a three-dimensional structure with a concave-convex structure, so as to better adapt to the flow field of the oil fume flow, and at the same time make the contact area of the oil fume flow larger when the air flow and...

Embodiment 2

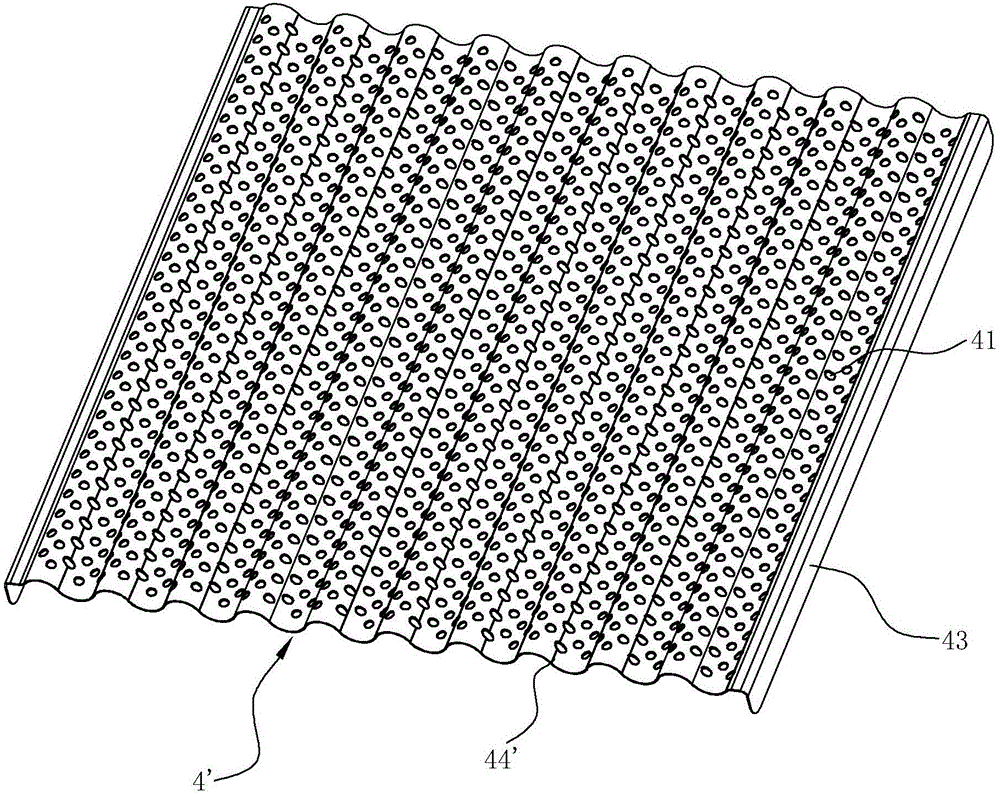

[0029] The difference from the first embodiment above is that in this embodiment, the concavo-convex structure is that the rectifying net 4' has a plurality of wavy structures 44' arranged side by side in the left and right directions.

Embodiment 3

[0031] The difference from the second embodiment above is that in this embodiment, the mesh 41' is a long hole, and the long hole extends in the left and right directions to reduce wind resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com