Processing device for stevia candy powder

A processing device and technology of stevioside, applied in lighting and heating equipment, food science, application, etc., can solve the problems of unsatisfactory crushing effect, easy to stay in, low drying efficiency, etc., achieve good crushing effect and avoid direct contact , Open the effect of high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

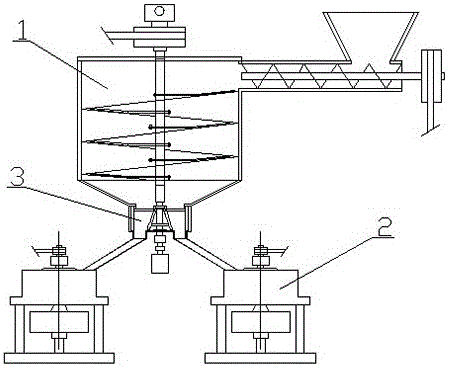

[0023] Such as figure 1 As shown, the processing device of stevia candy powder in this embodiment includes a drying mechanism 1, and a crushing mechanism 2 is connected to the bottom of the drying mechanism 1 through a corresponding pipeline.

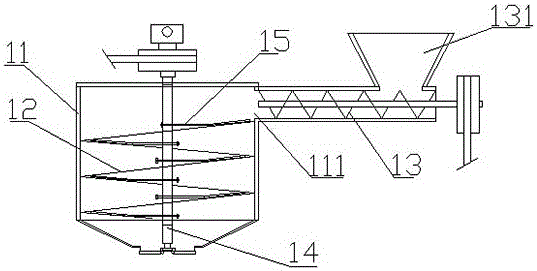

[0024] Such as figure 2 The shown drying mechanism 1 comprises a cylindrical drying box 11, a drying plate 12 placed in a refrigerant pipe and a heating pipe in the drying box 11, and the drying box 11 is a cylindrical box body that is airtight and can be evacuated. There is a feed port 111, and the drying plate 12 is arranged in the drying box 11 and is in a spiral shape, and is connected with the inner wall of the drying box 11. The center position of the drying box 11 is also vertically provided with a dial shaft 14, and the shaft 14 is provided with A plurality of material shifting rods 13, the material shifting rods 13 can be radially moved and arranged on some axial positions of the material shifting shaft 14, and the material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com