Attachment layer reinforced grid ribbed cylindrical shell structure

A ribbed shell and adhesion layer technology, which is applied to projectiles, self-propelled bombs, and offensive equipment, can solve problems such as the decline in ultimate bearing capacity, serious decline, and poor defect resistance of the bare shell structure, achieving improved The effect of bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

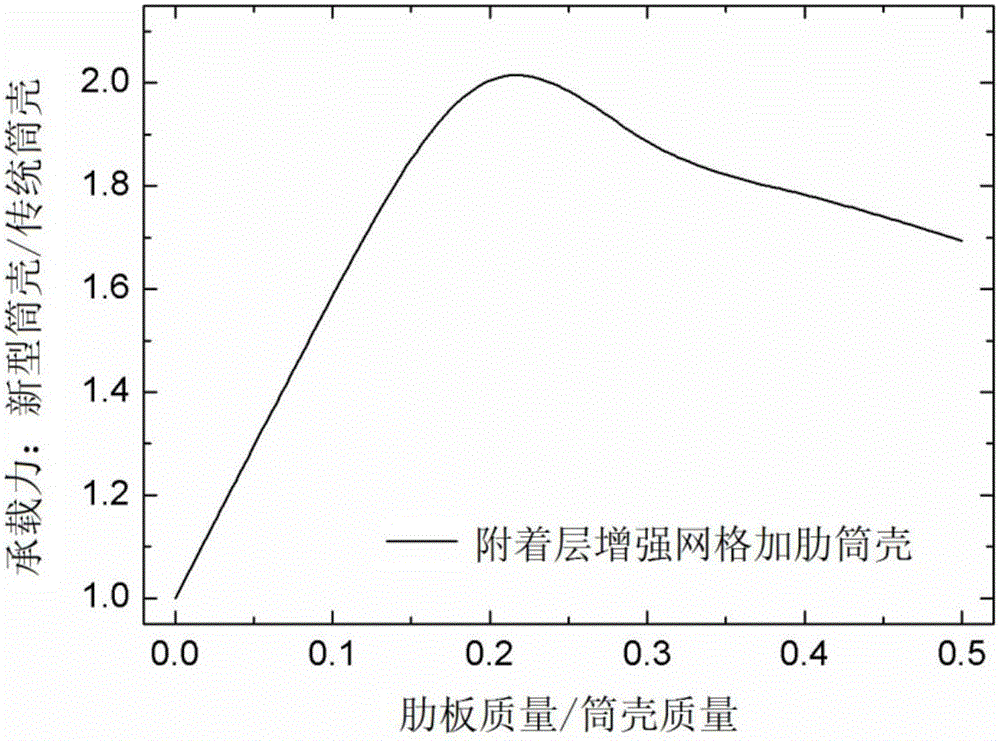

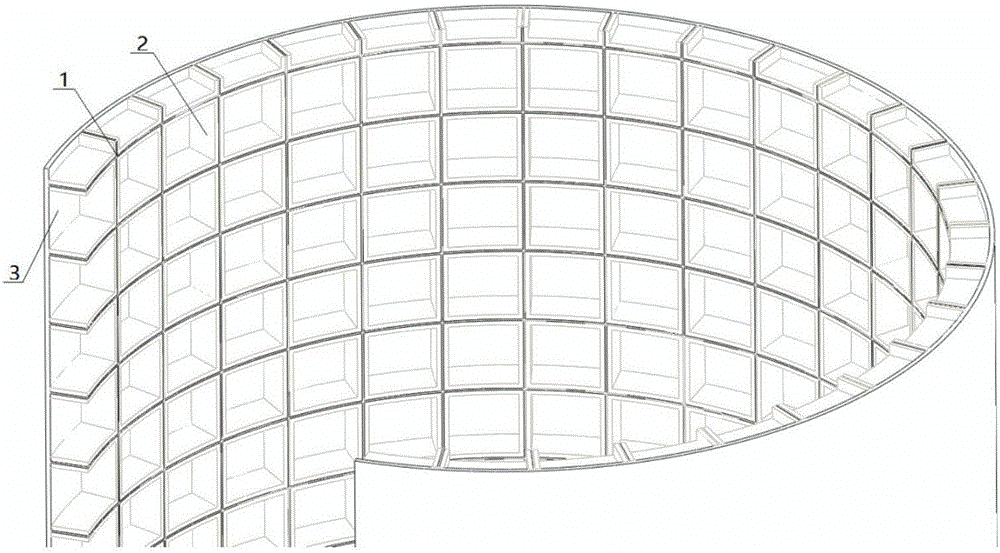

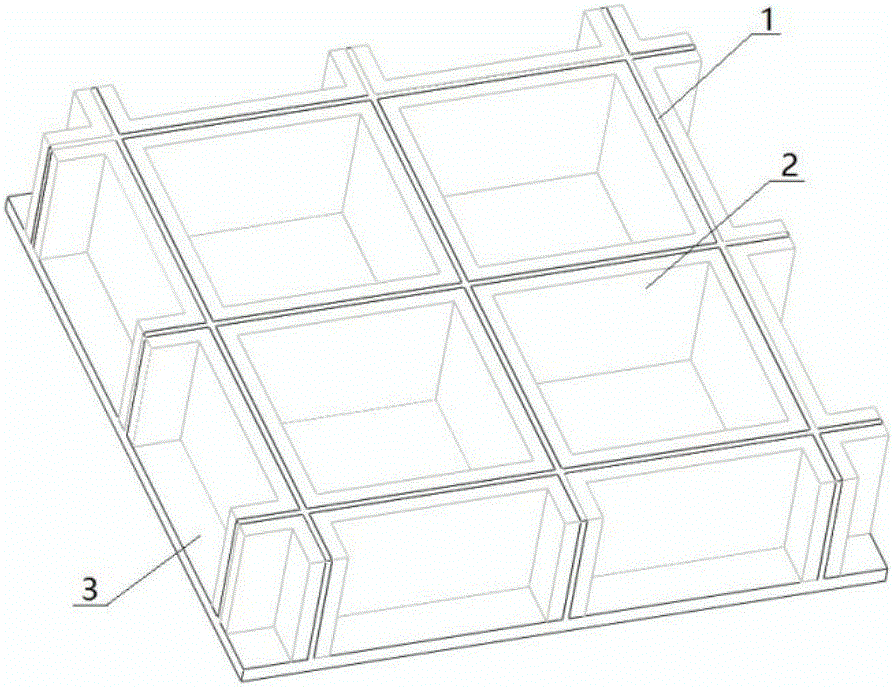

[0020] like Figure 1-3 As shown, the present invention is a new type of adhesion layer reinforced grid ribbed shell structure, adding a soft material adhesion layer 2 on the surface of a single rib plate 1 of the traditional grid ribbed structure, thereby improving the bending stiffness of the cross section of the rib plate. The density of the soft material adhesion layer 2 is smaller than that of the rib 1 material, and the height of the soft material adhesion layer 2 is the same as that of the rib 1 .

[0021] Wherein, the grid size, rib width, rib height, and attached soft layer 2 width of the grid ribbing 1 can be determined by analytical analysis or numerical optimization methods according to engineering indicators such as structural size, structural weight, and bearing capacity.

[0022] Wherein, the soft material of the adhesion layer refers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com