Method for measuring porosity of catalyst layer of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, which is applied in measurement devices, battery electrodes, circuits, etc., can solve problems such as large deviation of experimental results, mixing of catalyst layer and substrate pores, and difficulty in separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

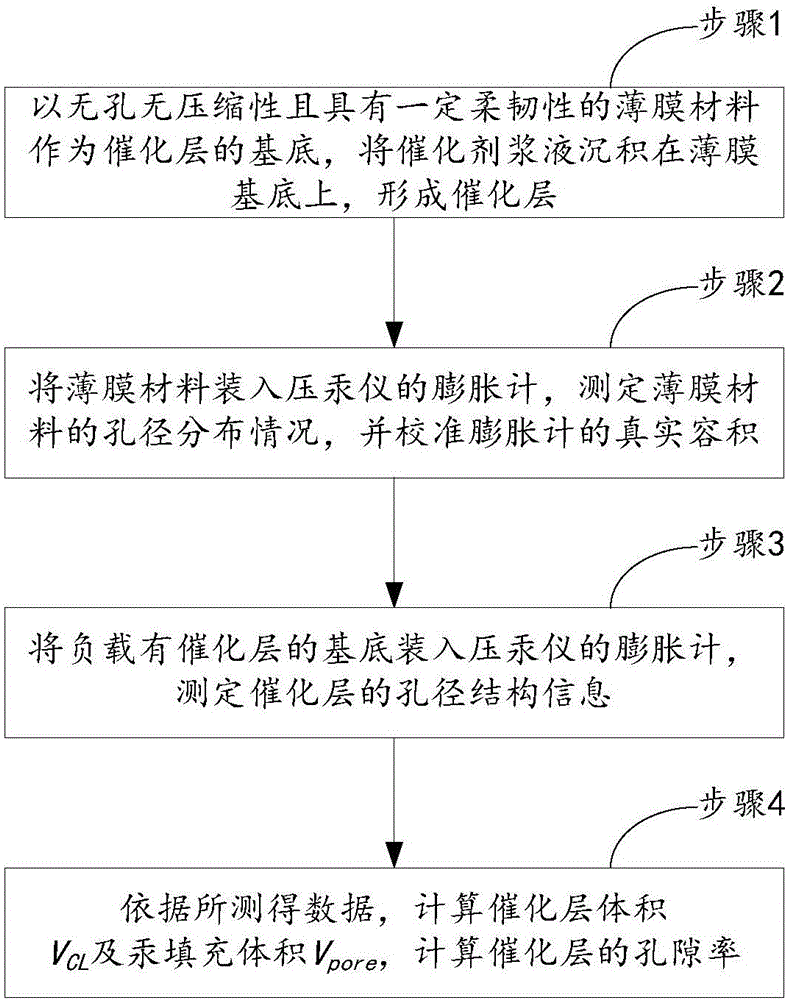

[0053] see figure 1 , the invention discloses a method for measuring the porosity of a catalytic layer of a proton exchange membrane fuel cell, said method comprising the steps of:

[0054] [Step 1] Use a non-porous, non-compressible and flexible film material as the substrate of the catalytic layer, and use brushing, spraying or printing processes to deposit the catalyst slurry on the film substrate to form a catalytic layer;

[0055] The base material of the catalytic layer is non-porous, non-compressible and has a certain degree of flexibility, and is a polytetrafluoroethylene or polyimide plastic film material, or a thin stainless steel sheet that can be wound; the base material of the catalytic layer requires be able to accurately measure its volume and mass;

[0056] [Step 2] Put the film material into the dilatometer of the mercury porosimeter, measure the pore size distribution of the film material, and calibrate the real volume of the dilatometer;

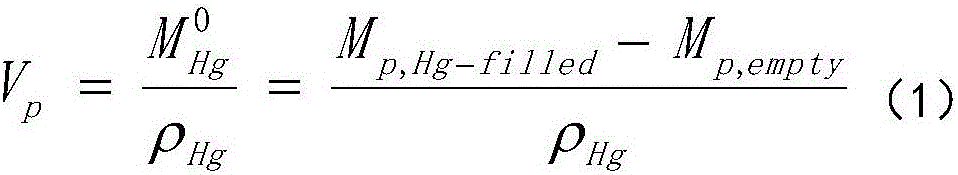

[0057] The volum...

Embodiment 1

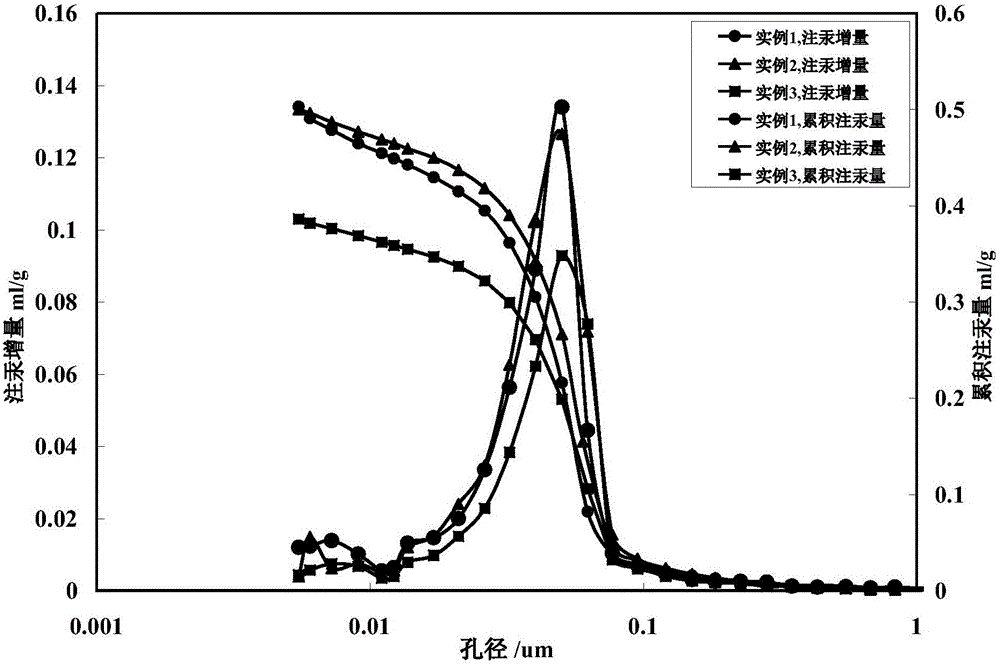

[0071] Example 1: Accurately weigh a certain mass of 40wt.% Pt / C (Johnson Matthey) catalyst, add a mixed solution of absolute ethanol and water (water: absolute ethanol = 1:10 volume ratio), mix well, and then add A certain volume of Nafion (Dupont) solution with a concentration of 5 wt.% was stirred and mixed evenly to obtain a catalyst slurry. Spray the catalyst slurry on 80cm by ultrasonic spraying 2 On the polyimide film, drying, the metal loading of the catalytic layer is 0.4mg Pt / cm 2 , the content of Nafion is 30wt.%. The porosity of the catalytic layer was measured and calculated according to the procedure.

Embodiment 2

[0072] Example 2: Accurately weigh a certain mass of 40wt.% Pt / C (Johnson Matthey) catalyst, add a mixed solution of absolute ethanol and water (water: absolute ethanol = 1:10 volume ratio), mix well, and then add A certain volume of Nafion (Dupont) solution with a concentration of 5 wt.% was stirred and mixed evenly to obtain a catalyst slurry. Spray the catalyst slurry on 80cm by ultrasonic spraying 2 On the PTFE film, drying, the metal loading of the catalytic layer is 0.4mg Pt / cm 2 , the content of Nafion is 30wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com