High-precision humidity sensor

A humidity sensor, high-precision technology, applied in the field of sensors, can solve problems such as large errors, and achieve the effects of high accuracy, improved accuracy and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

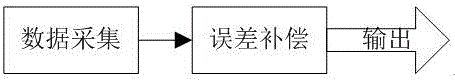

[0043] Such as figure 1 As shown, a high-precision humidity sensor includes a sequentially connected data acquisition unit and a segment compensation unit. The data acquisition unit collects humidity change data acquisition, and the segment compensation unit includes PSO-BP neural network error compensation.

[0044] PSO-BP neural network error compensation includes the following steps,

[0045] Step 1, set the relevant parameters of the PSO-BP neural network, 2 input and output nodes, 1 output node, 5 hidden layer nodes, the maximum number of iterations is 1500, and the target error is 1×10 -6 , the learning rate is 0.01, the population size is 40, and the inertia weight is 1. The total number of weight thresholds to be optimized by the PSO algorithm is: N=(m+1)×n+(n+1)×t, m is the input neuron The number of units, n is the number of neurons in the hidden layer, t is the number of neurons in the output layer, and the speed and position of the particles are randomly initializ...

Embodiment 2

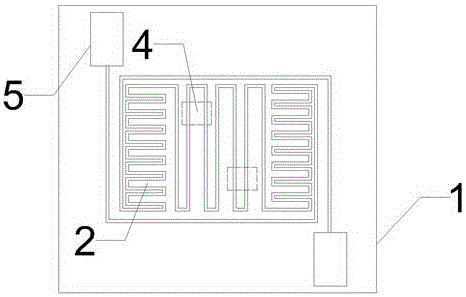

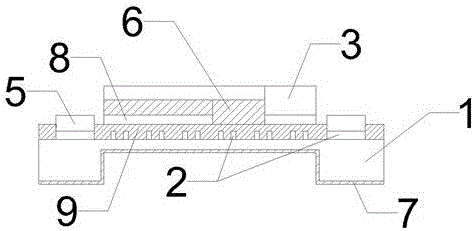

[0052] Such as Figure 2 to Figure 3 As shown, the data acquisition unit includes a humidity sensing device, the humidity sensing device includes a substrate 1, the thickness of the substrate 1 is 400 μm, the lower surface of the substrate 1 is covered with a substrate layer 7, the upper surface of the substrate 1 is provided with a heater 2, and the upper surface of the heater 2 is An output layer 6 is provided, and the upper surface of the output layer is covered with a moisture-sensitive layer 3 . The heater 2 is a serpentine heater, and the heater 2 includes three heating units, which are sequentially connected to the heating unit 1, heating unit 2 and heating unit 3 from left to right; one end of the heating unit 1 and the heating unit 3 are connected with electrodes 5. The other end is connected to both ends of heating unit two; heating unit one is arranged horizontally, heating unit one is mirror-symmetrical to heating unit three, heating unit two is arranged vertically...

Embodiment 3

[0057] Silane-alkyne block resins are prepared by:

[0058] Magnesium powder (6g, 0.25mol) and tetrahydrofuran (40ml) were added to a four-necked flask, and ethyl bromide (25.92g, 0.24mol) was added dropwise under a nitrogen atmosphere. Add m-diethynylbenzene (15.12g, 0.12mol) dropwise in an ice-water bath, reflux at 67°C for 1h, add dichloropolysiloxane (0.08mol) dropwise in an ice-water bath, and reflux for 2h to obtain the macromonomer Grignard Reagent P 1 . Magnesium powder (2.16g, 0.09mol) and tetrahydrofuran (40ml) were added into a four-necked flask, and bromoethane (8.64g, 0.08mol) was added dropwise under a nitrogen atmosphere. m-diethynylbenzene (5.04g, 0.04mol) was added dropwise in an ice-water bath, refluxed for 1h, dimethyldichlorosilane (7.74g, 0.06mol) was added dropwise in an ice-water bath, and refluxed for 2h to obtain a macromonomer Chlorosilane P 2 .

[0059] Will P 2 slowly drop to P 1 in the reaction system. After dripping, heat to reflux for abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com