Device and method for detecting water level of pressure vessel of nuclear power plant reactor

A pressure vessel and water level technology, applied in the field of nuclear safety, can solve the problems of inaccurate judgment of the deterioration degree of the water content of the pressure vessel and the inability to directly measure the temperature of the fuel cladding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

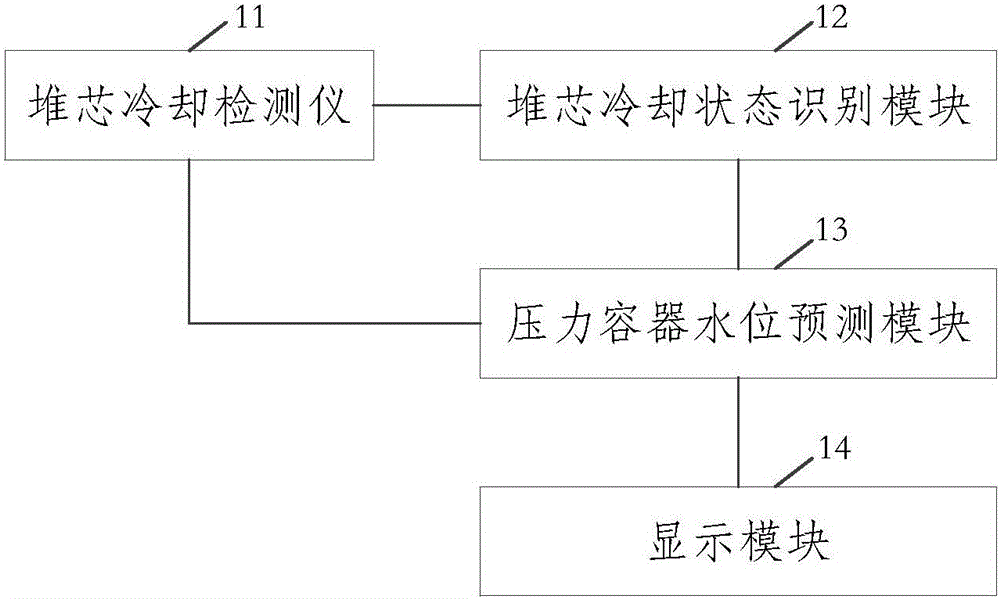

[0058] An embodiment of the present invention provides a device for detecting the water level of a nuclear power plant reactor pressure vessel, see figure 1 , figure 1 It is a device structure diagram of Embodiment 1 of the present invention, and the device includes:

[0059] The core cooling monitor 11 is installed in the primary circuit and connected with the pressure vessel, and is used to obtain the subcooling degree signal of the core outlet coolant and the status signal of the main pump;

[0060] The core cooling state identification module 12 is connected to the core cooling monitor 11, and is used to receive the subcooling signal and identify the temperature range where the subcooling signal is located;

[0061] The pressure vessel water level prediction module 13 is connected to the core cooling state identification module 12 and the core cooling monitor 11, receives the main pump state signal, and calculates the predicted pressure according to the temperature range ...

Embodiment 2

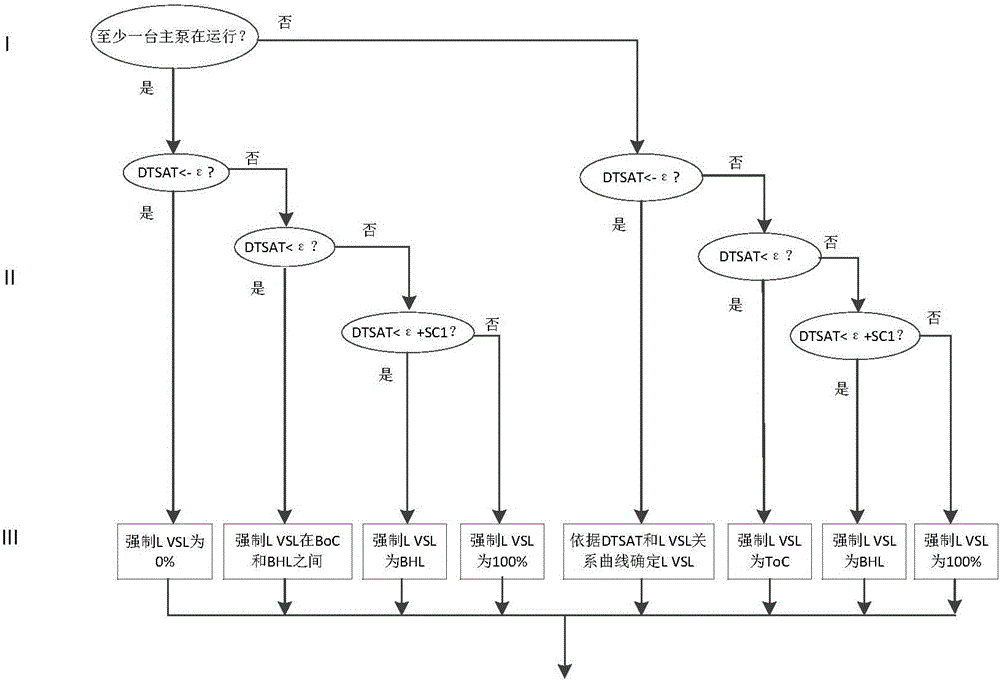

[0126] The implementation of the present invention provides a method for detecting the water level of the reactor pressure vessel of a nuclear power plant, which is applicable to the device for detecting the water level of the reactor pressure vessel of a nuclear power plant shown in Embodiment 1, see Figure 7 , the method includes:

[0127] Steps S01 and S02 respectively acquire the subcooling degree signal of the coolant at the core outlet and the state signal of the main pump.

[0128] In this embodiment, the existing core cooling monitor can be used to obtain the subcooling signal of the core outlet coolant and the main pump status signal, and then the core cooling state identification module receives the subcooling signal, and Identify the temperature range in which the subcooling signal is located.

[0129] Step S05, according to the temperature range of the main pump status signal and the subcooling degree signal, calculate and obtain the predicted water level of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com