Method for improving back stress of IGBT

A stress and organic adhesive technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as easy cracking of silicon wafers, and achieve the effect of reducing stress, improving stress, and improving cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

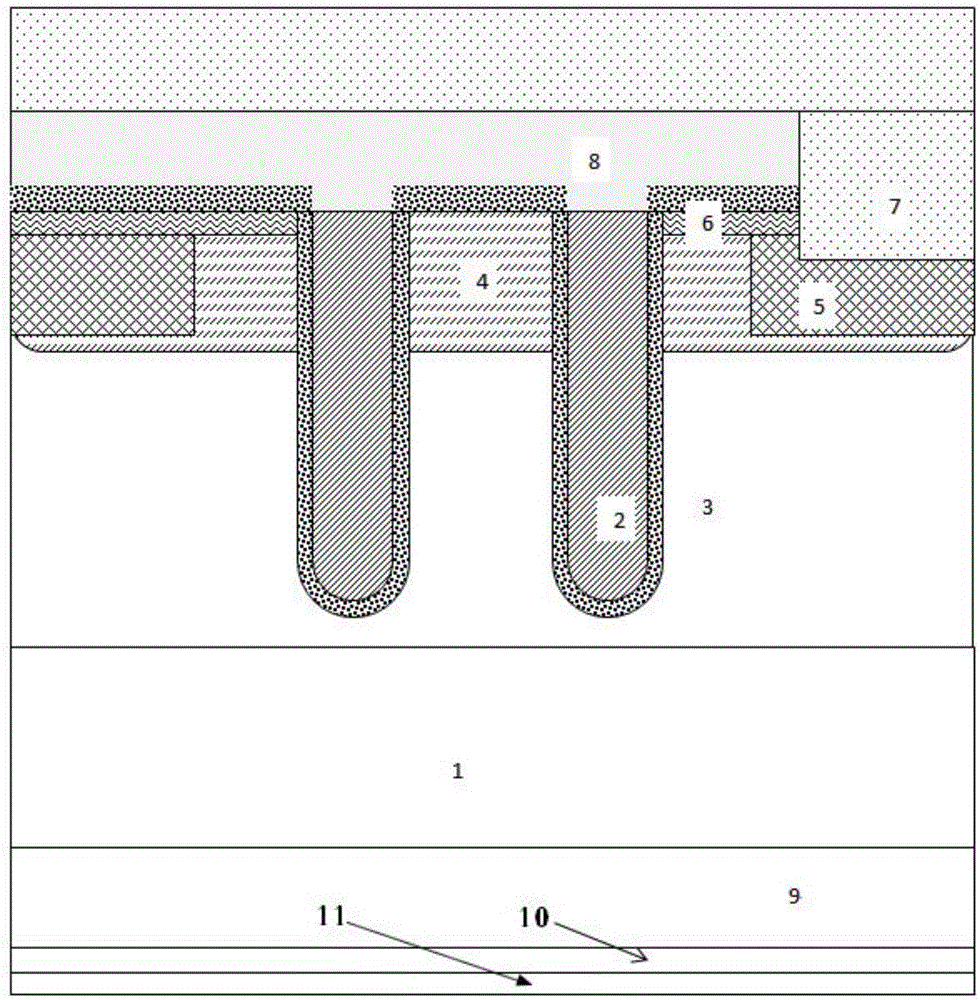

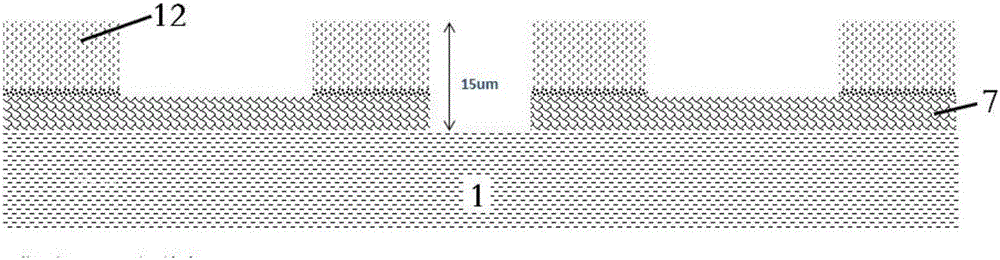

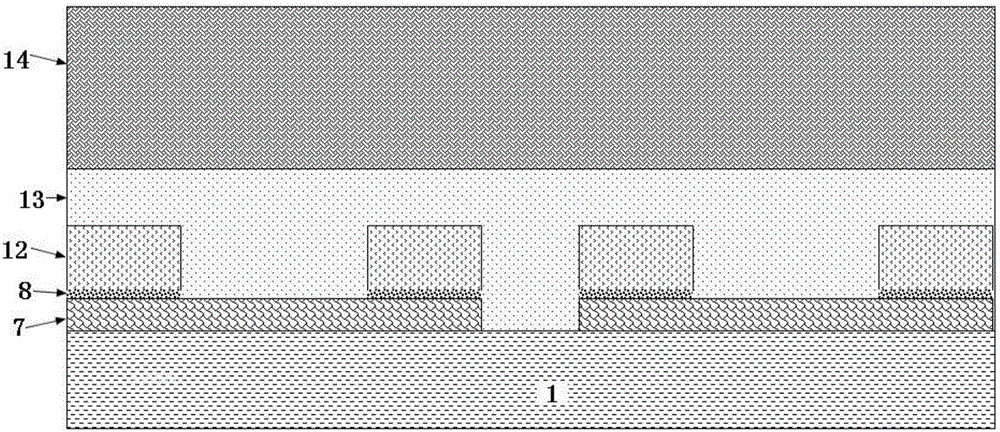

[0028] The method for improving IGBT stress described in the present invention, such as image 3 As shown, for the polyimide 12 covered on the passivation layer on the front side of the silicon wafer, after photolithography and etching patterning, an organic adhesive 13 is coated on the entire surface of the silicon wafer, and then a glass slide 14 is attached. The organic adhesive 13 is fully filled into the depressions and gaps after polyimide etching and patterning, and the glass slide 14 and the organic adhesive 13 together form a stress buffer layer.

[0029] The method for improving the back stress of the IGBT according to the present invention comprises the steps of:

[0030] In the first step, an organic adhesive with a thickness of 10-15 μm is spin-coated on a glass slide.

[0031] In the second step, an organic adhesive with a thickness of 10-15 μm is also coated on the front side of the silicon wafer.

[0032] In step 3, the front side of the silicon wafer is alig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com