Quad flat non-leaded package structure and leadframe thereof

A leadless packaging, square flat technology, used in semiconductor devices, semiconductor/solid-state device parts, electrical components, etc. problems such as abnormal sexual connection, to achieve the effect of improving yield and simplifying processing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

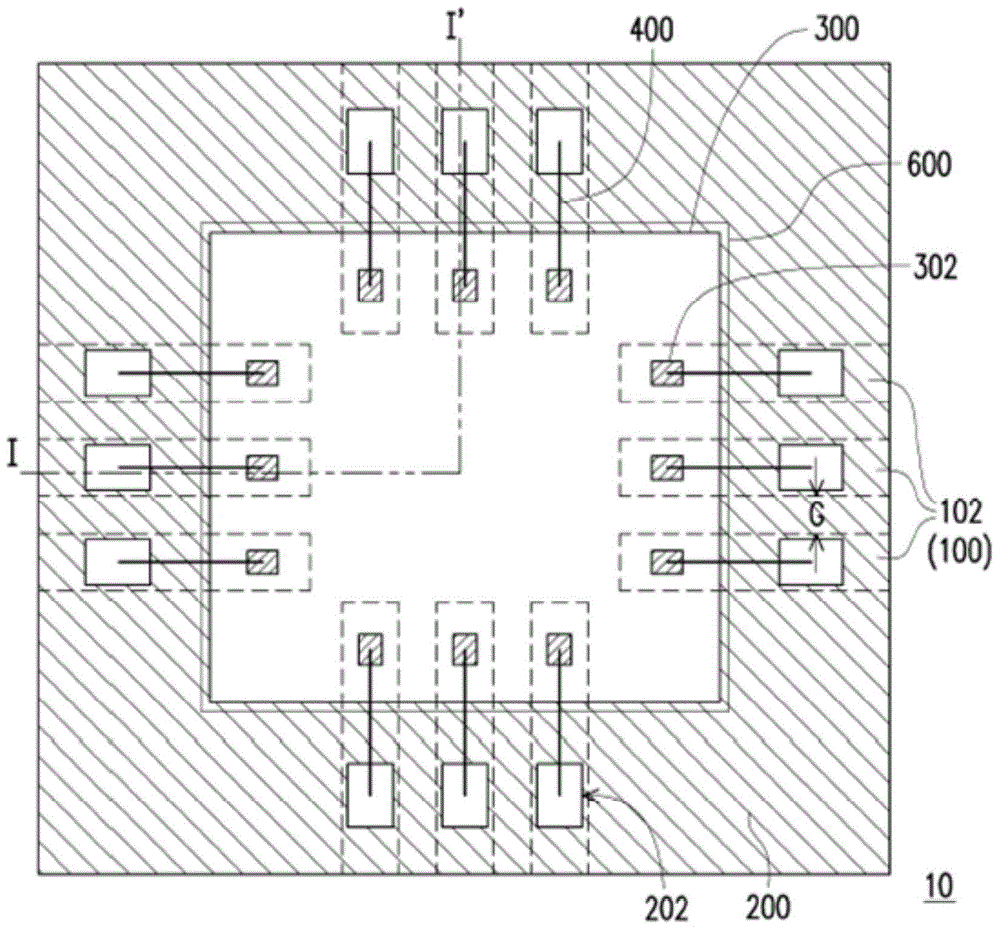

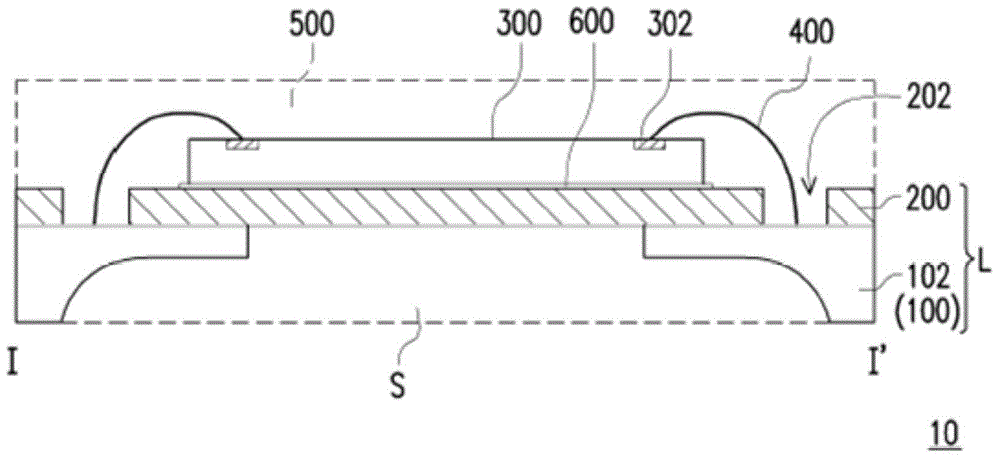

[0044] Figure 1A It is a top view of a quad flat no-lead package structure according to an embodiment of the present invention. Figure 1B for Figure 1A The cross-sectional schematic diagram of the quadflat no-lead package structure along the section line I-I'. Please also refer to Figure 1A and Figure 1B , in this embodiment, the QFN package structure 10 includes a lead frame 100 , a dielectric film 200 , a chip 300 , a plurality of bonding wires 400 and an encapsulant 500 . To clearly illustrate the present invention, the distribution range of the encapsulant 500 will be indicated by a dotted line, and the dielectric film 200 will be indicated by an oblique line. For the convenience of explanation below, the lead frame 100 drawn in the drawings of the present invention is only one of the units on the entire lead frame. In practice, the dielectric film 200 is a thin film formed corresponding to the size of the entire lead frame. In order to fully cover each unit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com