Image sensor module and manufacturing method thereof

A technology of image sensor and manufacturing method, applied in the sensor field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

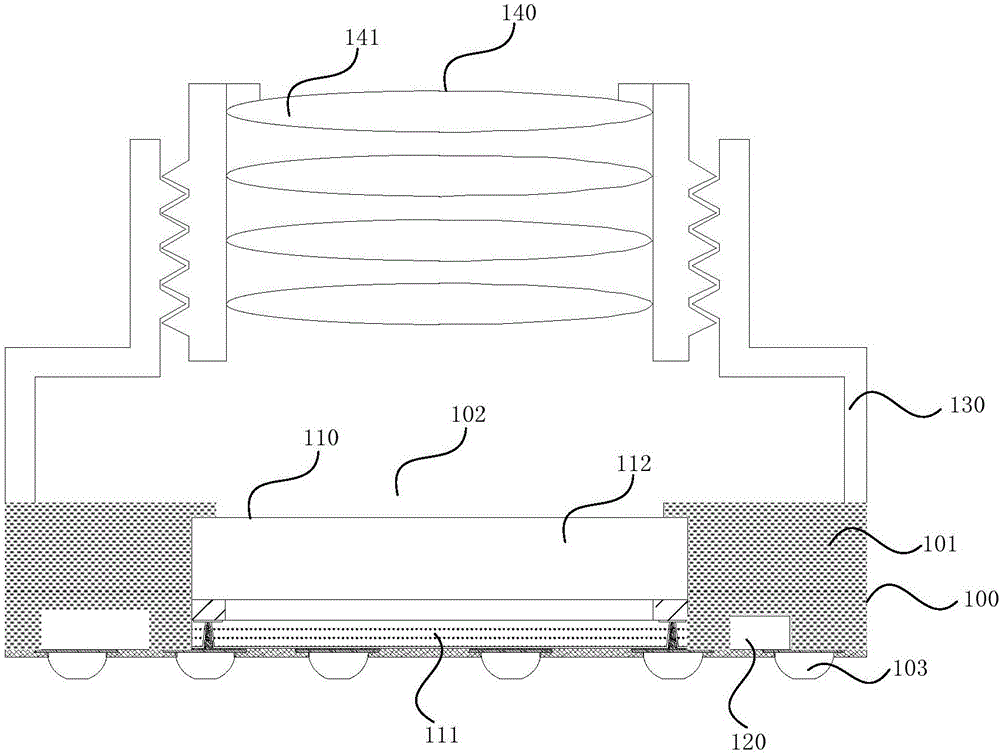

[0051] figure 1 It is a schematic structural diagram of the image sensor module provided by Embodiment 1 of the present invention. The image sensor module provided by the embodiments of the present invention can be applied to electronic devices such as smart phones, tablet computers, digital cameras, car driving recorders, and children's toys.

[0052] Such as figure 1 As shown, the image sensor module provided in this embodiment includes:

[0053] The image sensing chip 110 and at least one auxiliary chip 120, the image sensing chip 110 and at least one auxiliary chip 120 are packaged into a chip package 100 by the plastic packaging material 101, and the circuit of the image sensing chip 110 and at least one auxiliary chip 120 face in the same direction;

[0054] The image sensing chip 110 includes an image sensing unit 111, and an encapsulation glass 112 arranged above the light-incident surface of the image sensing unit 111. The front side of the above-mentioned chip pac...

Embodiment 2

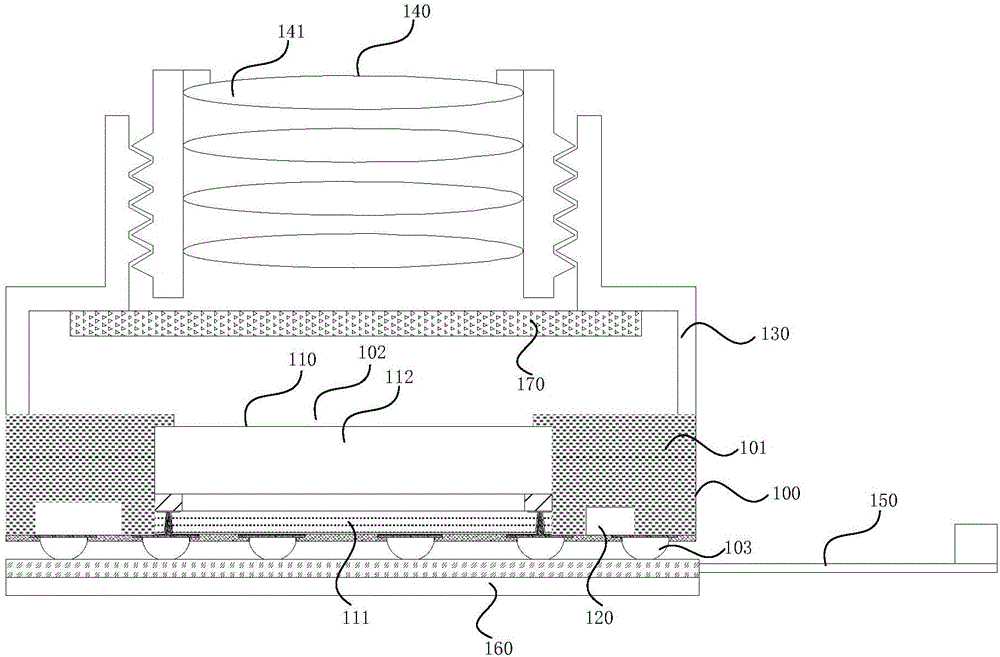

[0064] figure 2 It is a schematic structural diagram of the image sensor module provided by Embodiment 2 of the present invention. Such as figure 2 As shown, further, the image sensor module provided in this embodiment also includes a rigid-flex board 150 , wherein the rigid-flex board 150 includes a conductive circuit layer, and a plurality of solder joints arranged on the front surface of the rigid-flex board 150 The multiple pads are respectively electrically connected to the multiple bumps 103 on the redistribution pattern on the back of the chip package 100 .

[0065] Rigid-flex boards, that is, flexible circuit boards (FPC) and rigid circuit boards (PCB), are combined according to relevant process requirements after lamination and other processes to form circuit boards with FPC characteristics and PCB characteristics. The image sensor module provided by Embodiment 2 of the present invention is attached to the rigid-flex board 150. The rigid-flex board 150 has both a ...

Embodiment 3

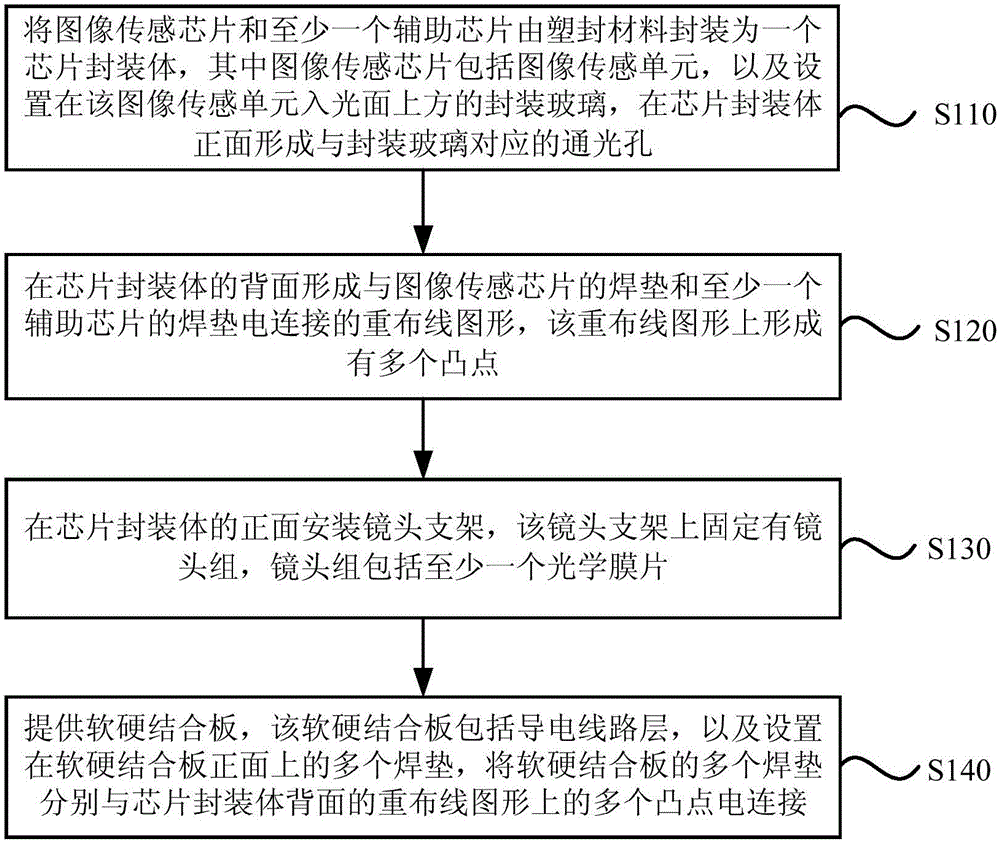

[0074] image 3 It is a flow chart of the manufacturing method of the image sensor module provided by the third embodiment of the present invention. This embodiment provides a method for manufacturing an image sensor module, including:

[0075] S110, packaging the image sensing chip and at least one auxiliary chip into a chip package with a plastic packaging material, wherein the image sensing chip includes an image sensing unit, and packaging glass arranged above the light-incident surface of the image sensing unit, A light hole corresponding to the packaging glass is formed on the front of the chip package;

[0076] S120, forming a rewiring pattern electrically connected to the bonding pad of the image sensor chip and the bonding pad of at least one auxiliary chip on the back of the chip package, and a plurality of bumps are formed on the rewiring pattern;

[0077] S130. Install a lens holder on the front surface of the chip package, a lens group is fixed on the lens holde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com