Electric car segmented dynamic wireless power supply system with low receiving power fluctuation

A technology for receiving power and electric vehicles, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of large system loss and difficulty in maintaining received power, and achieve the effect of small fluctuations in received power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

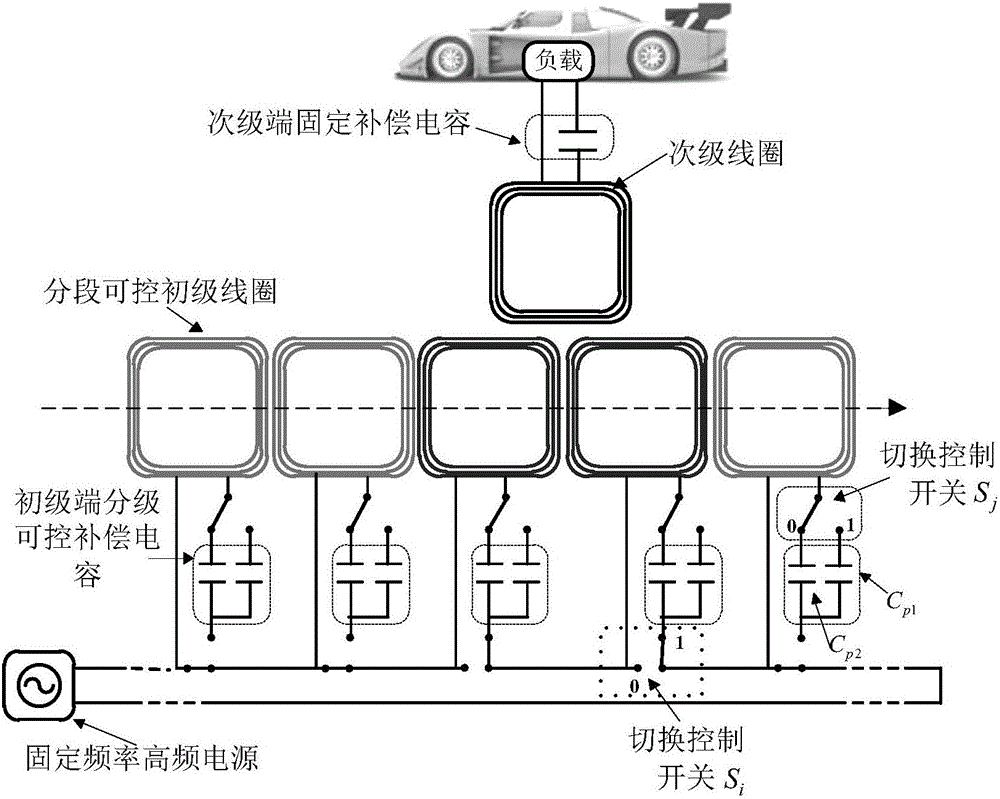

[0014] Such as figure 1 As shown, a segmented dynamic wireless power supply system for electric vehicles with low received power fluctuations, including a fixed-frequency high-frequency power supply, primary-side graded controllable compensation capacitors, segmented transmitting coils, switching control switches, receiving coils, and fixed secondary-side Compensation capacitor and electric vehicle load composition. The segmented transmitting coils are arranged along the path, and the design of each segmented transmitting coil and receiving coil is the same, and they are all square coils. The primary-side graded controllable compensation capacitor has the characteristics of graded controllability. Each transmitting coil is equipped with a primary-side graded controllable compensation capacitor. Each primary-side graded controllable compensation capacitor includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com