Presulfurization unit of heavy oil hydrogenation catalyst

A heavy oil hydrogenation and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

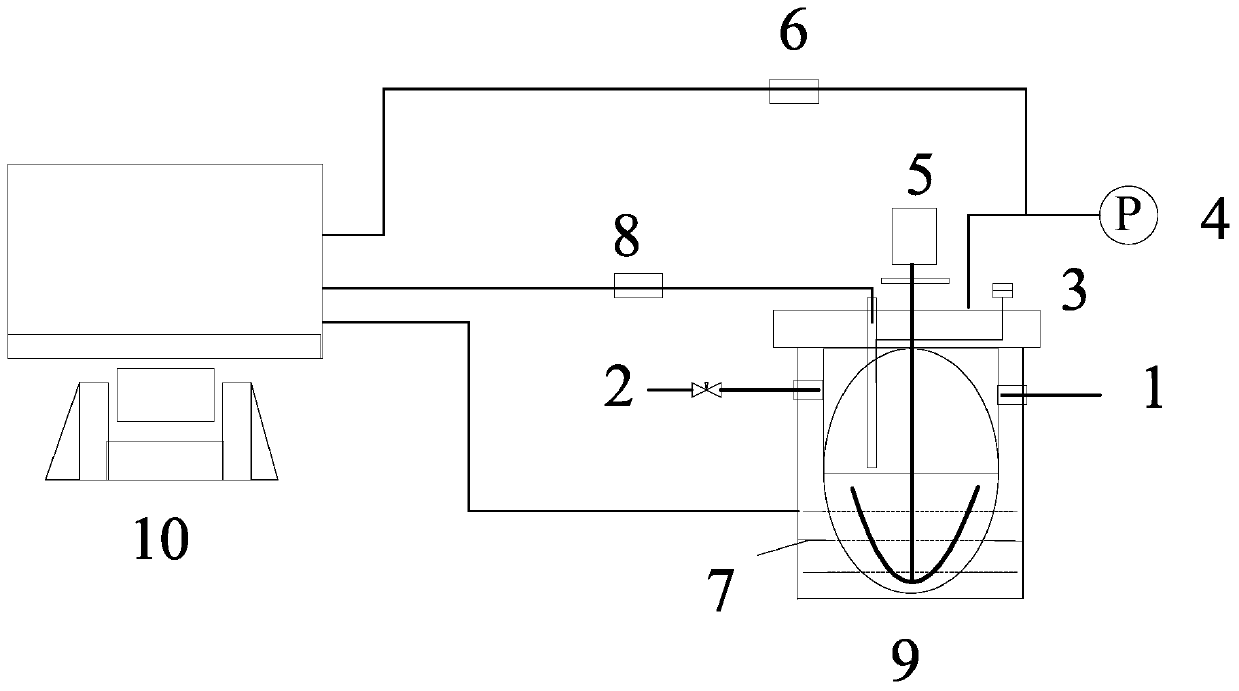

[0019] A kind of presulfurization device of heavy oil hydrogenation catalyst, such as figure 1 As shown, the device includes a computer control system, a vulcanization kettle, a temperature sensor, and a pressure sensor. The vulcanization kettle has a stirring function, and the kettle body is provided with a gas interface and a discharge interface. Gauge and pressure sensor, pressure, and temperature measuring equipment are arranged inside the kettle body, and the temperature measuring equipment is connected with the temperature sensor. The lower part of the kettle body is provided with a heating system. , The pressure sensor is connected.

[0020] A commercial hydrogenation catalyst was selected to investigate the effect of presulfidation.

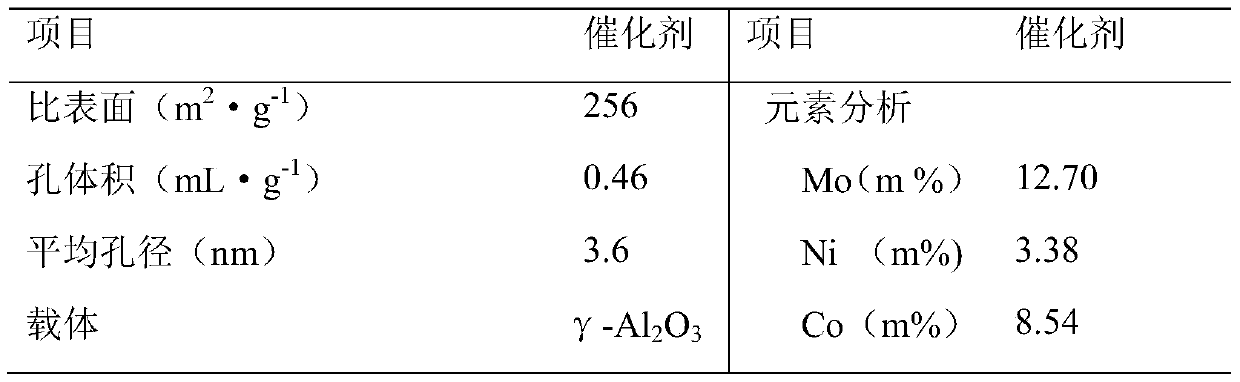

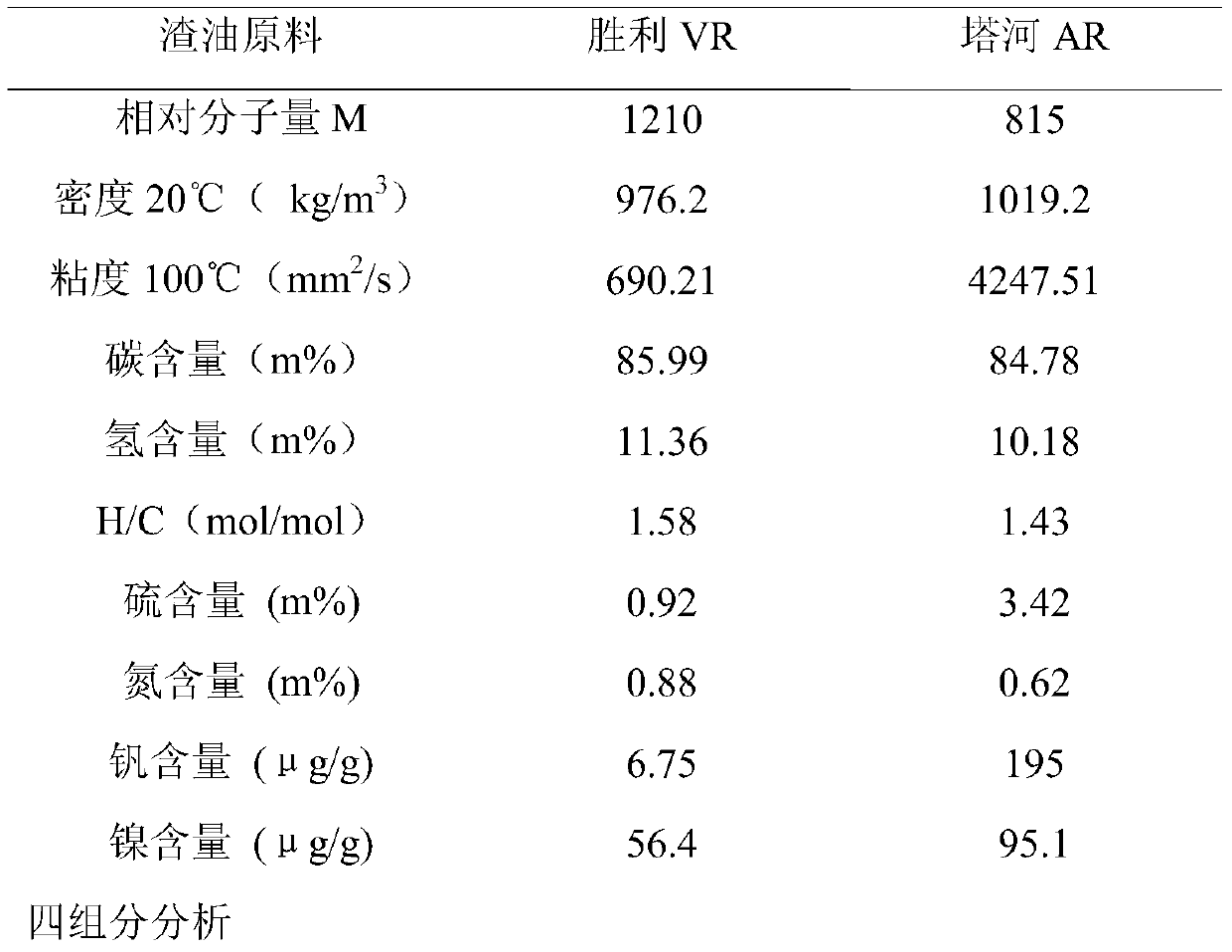

[0021] The FZC series hydrogenation catalyst FZC-41A developed by Fushun Petrochemical Research Institute was selected (see Table 1 for the basic properties of the catalyst). (AR) Suizhong 36-1AR and Tahe AR were used as raw materials f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com