Ozone catalyst for sewage treatment and preparation and sewage treatment method thereof

A technology for sewage treatment and catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, oxidized water/sewage treatment, etc. It can solve the problems of many by-products and complicated steps, and achieve the reduction of dosage, high preparation efficiency, and improved catalysis. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

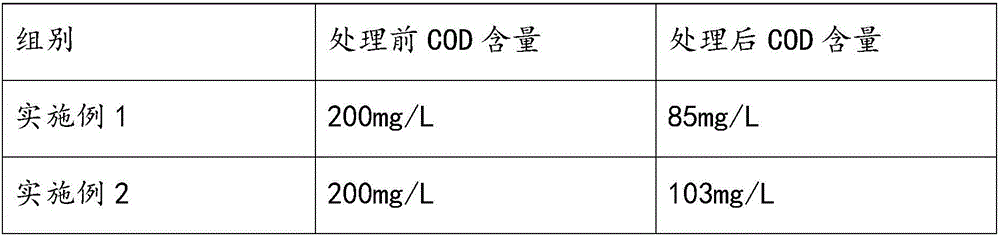

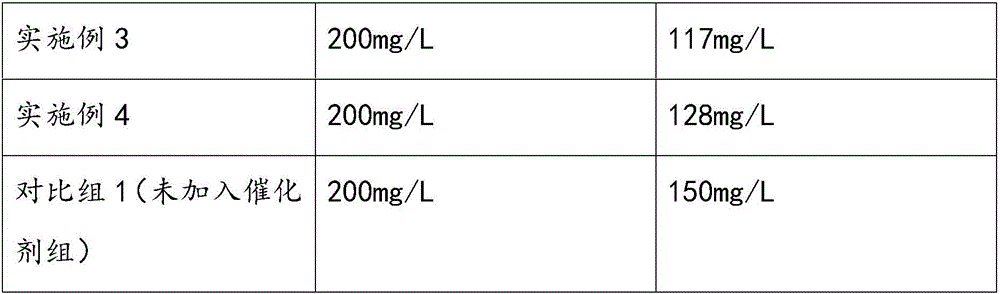

Examples

Embodiment 1

[0041] (1) Take an appropriate amount of diatomite, add water and stir evenly, and make diatomite particles with a particle size of 3-5mm;

[0042] (2) Weigh the MnO with a particle size of 0.1-1 mm according to the ratio of the mass of diatomite particles to the mass of catalytically active inorganic materials in a ratio of 1:8. 2 with Fe 2 o 3 Mixing metal oxide inorganic materials; then, using a sugar coating preparation machine to firmly wrap the two metal oxides on the surface of diatomite particles to generate a particle mixture;

[0043] (3) The particle mixture in step (2) was calcined at 800° C. for 2 hours to obtain the catalyst of Example 1.

[0044] Then, the particle size of the catalyst in Example 1 was detected, and the result showed that the particle size of the catalyst prepared in Example 1 was 5-7 mm.

Embodiment 2

[0046] (1) Take an appropriate amount of diatomite, add water and stir evenly, and make diatomite particles with a particle size of 2 to 2.5mm;

[0047] (2) Weigh the MnO with a particle size of 0.1-1 mm according to the ratio of the mass of diatomite particles to the mass of catalytically active inorganic materials in a ratio of 1:8. 2 with Fe 2 o 3 Mixing metal oxide inorganic materials; then, using a sugar coating preparation machine to firmly wrap the two metal oxides on the surface of diatomite particles to generate a particle mixture;

[0048] (3) The particle mixture in step (2) was calcined at 800° C. for 2 hours to obtain the catalyst of Example 2.

[0049] Then, the particle size of the catalyst in Example 2 was detected, and the result showed that the particle size of the catalyst prepared in Example 2 was 4-4.5 mm.

Embodiment 3

[0051] (1) Take an appropriate amount of diatomite, add water and stir evenly, and make diatomite particles with a particle size of 5.5-6mm;

[0052] (2) Weigh the MnO with a particle size of 0.1-1 mm according to the ratio of the mass of diatomite particles to the mass of catalytically active inorganic materials in a ratio of 1:8. 2 with Fe 2 o 3 Mixing metal oxide inorganic materials; then, using a sugar coating preparation machine to firmly wrap the two metal oxides on the surface of diatomite particles to generate a particle mixture;

[0053] (3) The particle mixture in step (2) was calcined at 800° C. for 2 hours to obtain the catalyst of Example 3.

[0054] Then, the particle size of the catalyst in Example 3 was detected, and the result showed that the particle size of the catalyst prepared in Example 3 was 7.5-8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com