A kind of modified bamboo fiber polylactic acid composite material for automotive interior decoration

A composite material and bamboo fiber technology, applied in the field of plastic processing, can solve the problems of poor thermal stability and flammability of polylactic acid plastics, achieve excellent mechanical properties and improve flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

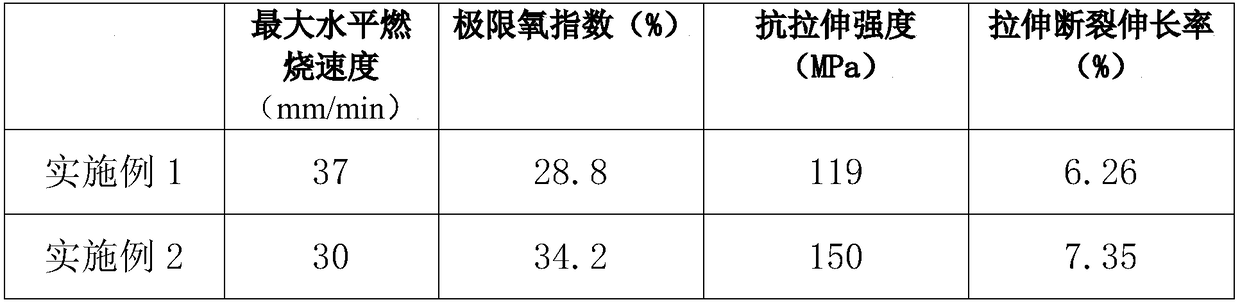

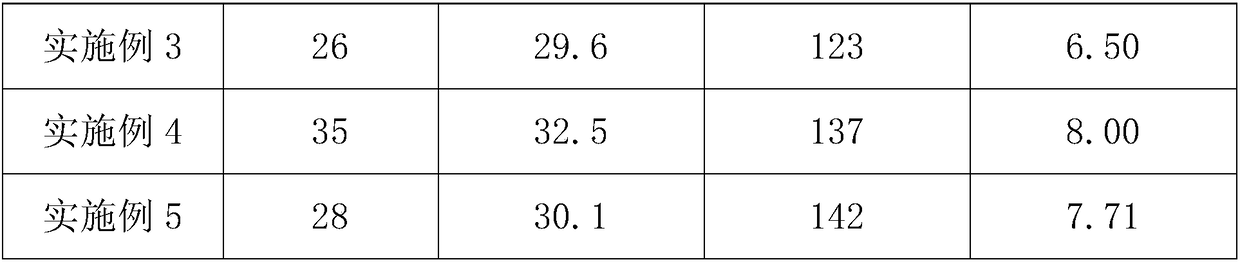

Examples

Embodiment 1

[0029] A modified bamboo fiber polylactic acid composite material for automotive interior, which is prepared by the following method:

[0030] (1) bamboo fiber degumming treatment:

[0031] Chemical degumming method for degumming treatment;

[0032] (2) Microbial fermentation modified bamboo fiber:

[0033] Bacillus licheniformis, Bacillus amyloliquefaciens, and Acetobacter xylinum are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.3:0.8;

[0034] Wash the degummed bamboo fibers, spray the bacteria evenly, and ferment at 38°C for 96 hours. After the fermentation is over, wash them with warm water, shake them loose, and dry them;

[0035] (3) Blending of raw materials:

[0036] Set the temperature at 160°C, preheat for 1 hour, and configure the dried raw materials according to the following parts by weight: 12 parts of modified bamboo fiber, 95 parts of polylactic acid, 0.5 part of chitosan powder; 0.5 part of nanometer talc powder, ca...

Embodiment 2

[0043] A modified bamboo fiber polylactic acid composite material for automotive interior, which is prepared by the following method:

[0044] (1) bamboo fiber degumming treatment:

[0045] Chemical degumming method for degumming treatment;

[0046] (2) Microbial fermentation modified bamboo fiber:

[0047] Bacillus licheniformis, Bacillus amyloliquefaciens, and Acetobacter xylinum are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.5:0.8;

[0048] Wash the degummed bamboo fibers, spray the bacteria agent evenly, and ferment at 38°C for 50 hours. After the fermentation is over, wash them with warm water, shake them loose, and dry them;

[0049] (3) Blending of raw materials:

[0050] Set the temperature to 160°C, preheat for 1 hour, and configure the dried raw materials according to the following parts by weight: 18 parts of modified bamboo fiber, 80 parts of polylactic acid, 0.5 part of chitosan powder; 0.5 part of nano-smectite talc ...

Embodiment 3

[0057] A modified bamboo fiber polylactic acid composite material for automotive interior, which is prepared by the following method:

[0058] (1) bamboo fiber degumming treatment:

[0059] Chemical degumming method for degumming treatment;

[0060] (2) Microbial fermentation modified bamboo fiber:

[0061] Bacillus licheniformis, Bacillus amyloliquefaciens, and Acetobacter xylinum are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.4:0.8;

[0062] Wash the degummed bamboo fibers, spray the bacteria agent evenly, and ferment at 38°C for 90 hours. After the fermentation is over, wash them with warm water, shake them loose, and dry them;

[0063] (3) Blending of raw materials:

[0064] Set the temperature at 160°C, preheat for 1 hour, and configure the dried raw materials according to the following parts by weight: 13 parts of modified bamboo fiber, 94 parts of polylactic acid, 0.5 part of chitosan powder; 0.5 part of nano-smectite powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com