Application of box-type extraction tank in extracting boron in salt lake brine

A box-type extraction tank and salt lake brine technology, applied in the direction of boron oxyacids, boron oxide compounds, etc., can solve the problems of unsatisfactory mixing effect and layering effect, high equipment price, high operating cost, etc., and achieve low maintenance cost , easy operation and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

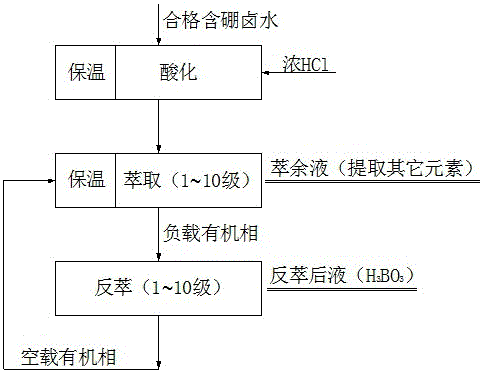

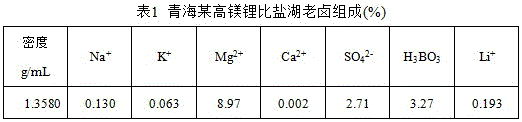

[0021] Such as figure 1 As shown in the flow chart, hydrochloric acid is added to acidify the brine after pressure filtration. After acidification, the pH of the brine is 2.0. The extractant used is 2-hexyldecanol, and the diluent is sulfonated kerosene. The volume ratio of the two is 1:5. (O / A)=2:1, the number of extraction stages is 2, the single-stage extraction time is 5min, and the clarification time is 15min. The extraction time was 5 minutes, the acidity value of the back-extraction aqueous phase was pH=0.05, the extraction temperature was 50°C, and the back-extraction temperature was room temperature, all of which were countercurrent extractions. The obtained stripping solution was evaporated, cooled, filtered (including washing), and dried to measure Na in the product. + 、K + , Mg 2+ , Ca 2+ , SO 4 2- , Cl - , Fe 3+ The percentage content of boric acid is 0.0032%, 0.0014%, 0.0045%, 0.0013%, 0.0050%, 0.009%, 0.0005%, respectively, and the boric acid content is ...

Embodiment 2

[0023] After the old brine is filtered, add sulfuric acid to acidify. After acidification, the pH of the brine is 1.0. The extractant used is mixed alcohol (isooctanol: n-dodecyl alcohol = 5:1), and the diluent is aviation kerosene. The volume ratio of the two is 1. : 1, extraction ratio (O / A)=1:1, extraction stages 5 stages, single-stage extraction time 3min, clarification time 10min, stripping ratio (O / A)=3:1, stripping stages 5 stages, single-stage back extraction time 6min, acidity value of back extraction aqueous phase pH = 1, extraction temperature 40°C, back extraction temperature at room temperature, all countercurrent extraction. The obtained stripping solution was evaporated, cooled, filtered (including washing), and dried to measure Na in the product. + 、K + , Mg 2+ , Ca 2+ , SO 4 2- , Cl - , Fe 3+ The percentage content of boric acid is 0.0033%, 0.0015%, 0.0040%, 0.0013%, 0.0045%, 0.01%, 0.0005%, respectively, and the content of boric acid is 99.9%, reaching...

Embodiment 3

[0025] After filtering the old brine plate, add hydrochloric acid to acidify. After acidification, the pH of the brine is 0.5. The extractant used is mixed alcohol (pentyl alcohol: n-heptanol = 10:1), and the diluent is solvent gasoline. The volume ratio of the two is 2:1, extraction ratio (O / A)=1:5, extraction stages 10, single-stage extraction time 8min, clarification time 12min, stripping ratio (O / A)=10:1, stripping stage The number of stages is 10, the single-stage back-extraction time is 8 minutes, the acidity value of the back-extraction aqueous phase is pH=0.01, the extraction temperature is 30°C, and the back-extraction temperature is room temperature, all of which are countercurrent extractions. The obtained stripping solution was evaporated, cooled, filtered (including washing), and dried to measure Na in the product. + 、K + , Mg 2+ , Ca 2+ , SO 4 2- , Cl - , Fe 3+ The percentage content of boric acid is 0.0030%, 0.0015%, 0.0045%, 0.0014%, 0.0044%, 0.01%, 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com