Multi-stage microfluidisation and deep filtration integrated type improved anaerobic filter

An anaerobic filter and microfluidization technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of insufficient treatment of polluted wastewater, dead zone, Channeling and other problems, to achieve the effect of easy growth of biofilm, sufficient contact and suitable volume space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

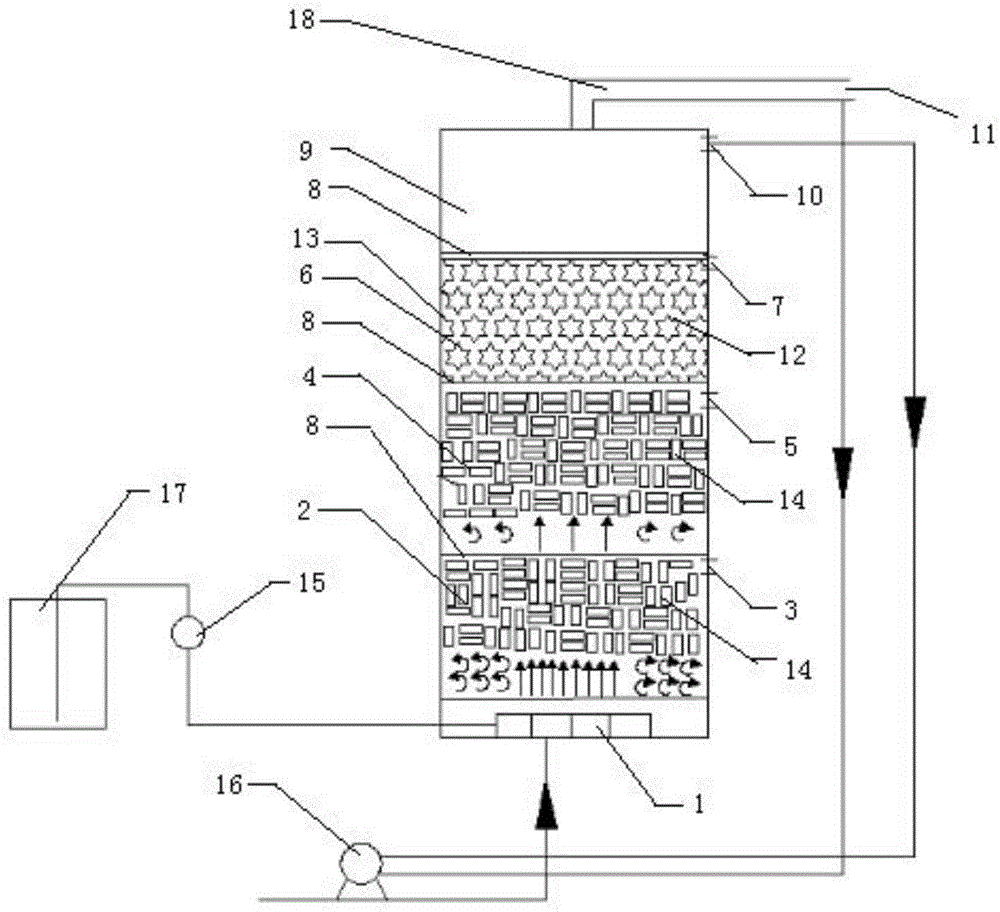

[0025] as attached figure 1 Shown is an improved anaerobic filter 13 with multi-stage microfluidization and depth filtration. The inside of the anaerobic filter 13 is sequentially provided with a water distribution area with a water distributor 1 and a strong Strong microfluidized packing area 2 with sampling port 3 in microfluidized packing area, weak microfluidized packing area 4 with sampling port 5 in weak microfluidized packing area, filter packing area 6 with sampling port 7 in filter packing area , a water outlet area 9 with a water outlet 10 and a biogas collection system (not shown) with an air outlet 11 communicated with the water outlet 9 through a biogas pipeline 18 and the strong microfluidization packing area 2, weak microfluidization A detachable porous partition 8 is arranged between the packing area 4, the filter packing area 6, and the water outlet area 9; the holes of the porous partition 8 are evenly distributed and the pore diameter is less than 1 cm, and ...

Embodiment 2

[0031] as attached figure 1 Shown is an improved anaerobic filter 13 with multi-stage microfluidization and depth filtration. The inside of the anaerobic filter 13 is sequentially provided with a water distribution area with a water distributor 1 and a strong Strong microfluidized packing area 2 with sampling port 3 in microfluidized packing area, weak microfluidized packing area 4 with sampling port 5 in weak microfluidized packing area, filter packing area 6 with sampling port 7 in filter packing area , a water outlet area 9 with a water outlet 10 and a biogas collection system (not shown) with an air outlet 11 communicated with the water outlet 9 through a biogas pipeline 18 and the strong microfluidization packing area 2, weak microfluidization A detachable porous partition 8 is arranged between the packing area 4, the filter packing area 6 and the water outlet area 9; the holes of the porous partition 8 are evenly distributed and the pore diameter is less than 1 cm; the w...

Embodiment 3

[0037] as attached figure 1 Shown is an improved anaerobic filter 13 with multi-stage microfluidization and depth filtration. The inside of the anaerobic filter 13 is sequentially provided with a water distribution area with a water distributor 1 and a strong Strong microfluidized packing area 2 with sampling port 3 in microfluidized packing area, weak microfluidized packing area 4 with sampling port 5 in weak microfluidized packing area, filter packing area 6 with sampling port 7 in filter packing area , a water outlet area 9 with a water outlet 10 and a biogas collection system (not shown) with an air outlet 11 communicated with the water outlet 9 through a biogas pipeline 18 and the strong microfluidization packing area 2, weak microfluidization A detachable porous partition 8 is arranged between the packing area 4, the filter packing area 6 and the water outlet area 9; the holes of the porous partition 8 are evenly distributed and the pore diameter is less than 1 cm; the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com