Preparation method of lightweight slats for building partition walls

A light-weight, slatted technology, applied in buildings, building components, building structures, etc., can solve the problems of poor noise reduction and heat insulation performance, high production costs, and poor environmental protection, and achieve steel saving, light weight, and cement saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

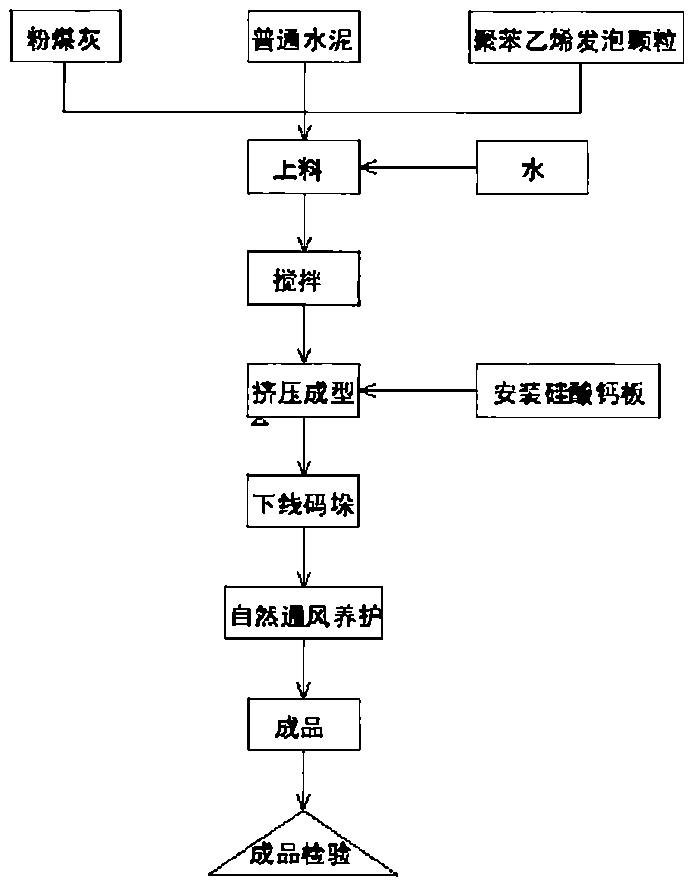

[0017] Embodiment one: a kind of preparation method of light-weight batten for building partition wall, such as figure 1 As shown, the method includes the following steps:

[0018] (1) Put 62Kg of fly ash, 320Kg of cement, 2.94Kg of polystyrene foamed particles, and 304.7Kg of pottery sand into the feeding device, and add 160Kg of water to stir and an appropriate amount of physical expansion agent, and stir for 10-15 minutes ;

[0019] (2) Extrusion after installation of calcium silicate board to obtain semi-finished lightweight slats, and better flame retardancy after installation of calcium silicate board;

[0020] (3) Palletize the above-mentioned lightweight slats off-line, and place ten lightweight slats from bottom to top to form a stack. There is a ventilation space between the left and right and front and rear adjacent stacks, and the upper and lower adjacent A support rod is set between the two stacks, and under the action of the support rod, there is a ventilation ...

Embodiment 2

[0023] Embodiment two: a kind of preparation method of light-weight lath for building partition wall, such as figure 1 As shown, the method includes the following steps:

[0024] (1) Put 64Kg of fly ash, 310Kg of cement, 3.15Kg of polystyrene foam particles, and 439.6Kg of pottery sand into the feeding device, and add 150Kg of water to stir and an appropriate amount of physical expansion agent, and stir for 10-15 minutes ;

[0025] (2) Install the calcium silicate board and then extrude it to obtain a semi-finished lightweight strip

[0026] (3) Palletize the above-mentioned lightweight slats off-line, and place ten lightweight slats from bottom to top to form a stack. There is a ventilation space between the left and right and front and rear adjacent stacks, and the upper and lower adjacent A wooden pallet is set between the two stacks, and the ventilation space is formed between the upper and lower adjacent two stacks under the action of the wooden pallet;

[0027] (4) Ma...

Embodiment 3

[0029] Embodiment three: a kind of preparation method of light-weight batten for building partition wall, such as figure 1 As shown, the method includes the following steps:

[0030] (1) Put 66Kg of fly ash, 330Kg of cement, 2.45Kg of polystyrene foamed particles, and 380Kg of pottery sand into the feeding device, and add 170Kg of water to stir and an appropriate amount of physical expansion agent, and stir for 10-15 minutes;

[0031] (2) Extrusion molding after installing the calcium silicate board to obtain semi-finished lightweight slats;

[0032] (3) Palletize the above-mentioned lightweight slats off-line, and place ten lightweight slats from bottom to top to form a stack. There is a ventilation space between the left and right and front and rear adjacent stacks, and the upper and lower adjacent Wooden pallets are set between the two stacks, and under the action of the wooden pallets, there is a ventilation space between the upper and lower adjacent stacks;

[0033] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com