Dust-containing high temperature oil gas washing and cooling device and washing and cooling method

A cooling device, oil and gas technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of increased difficulty and cost of separation, high ash content of high-temperature coal tar gas, equipment corrosion, etc., to reduce separation cost, reduce the degree of corrosion, and reduce the effect of ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

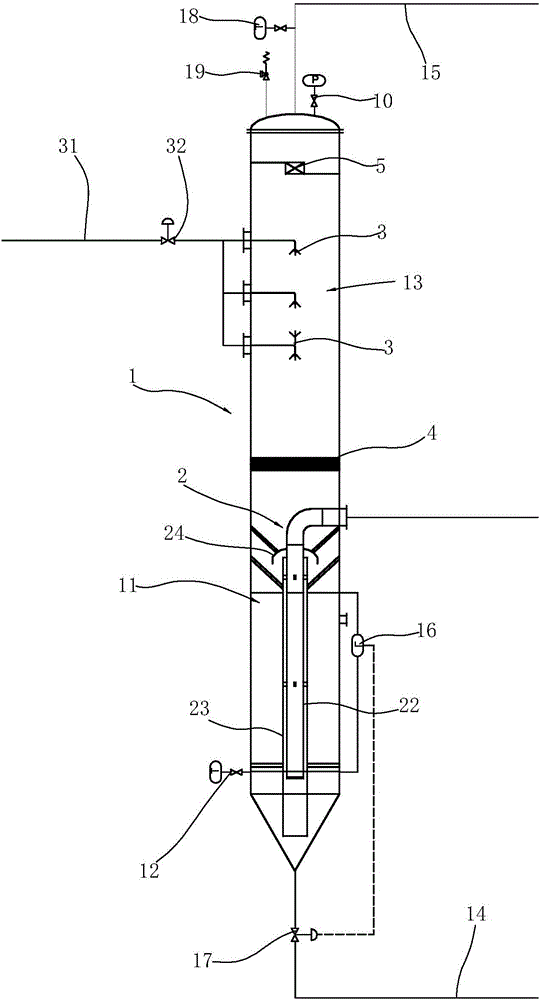

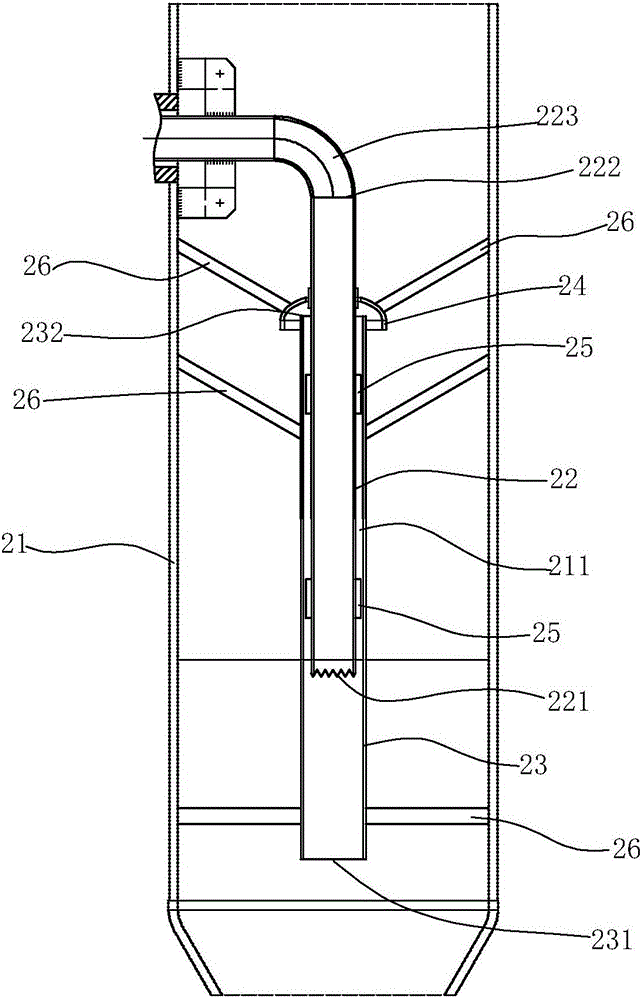

[0039] Such as figure 1 and figure 2 As shown, the dust-containing high-temperature oil-gas washing and cooling device includes:

[0040] The washing tower 1 is provided with a grid 4 in the middle, which divides the inner cavity of the washing tower 1 into a lower washing area 11 and an upper spraying area 13 .

[0041] A spraying device 3 is provided in the spraying area 13, and the inlet of the spraying device 3 is connected to the external spraying liquid pipeline 31; there are three spraying devices in this embodiment, arranged at intervals along the height direction of the spraying area. The spraying device can be selected from any one of the prior art as required.

[0042] The spray pipe 31 is provided with a first regulating valve 32 for regulating the flow rate of the spraying medium; correspondingly, a first temperature detector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com