Process method for controlling non-martensite depth of carburized workpiece

A non-martensitic and process technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of not effectively reducing the depth of non-martensite on the surface of deep carburized workpieces and reducing the surface of workpieces. Hardness, wear resistance, affecting the contact fatigue strength of the workpiece and other issues, to achieve the effect of improving comprehensive mechanical properties, increasing stability, and increasing hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention discloses a process method for controlling the non-martensitic depth of a carburized workpiece, which comprises the following steps:

[0037] Clean the workpiece to be carburized in advance, especially to ensure that there is no oil and other impurities on the surface of the tooth profile, and at the same time, do anti-seepage treatment on the part of the workpiece that does not need to be carburized.

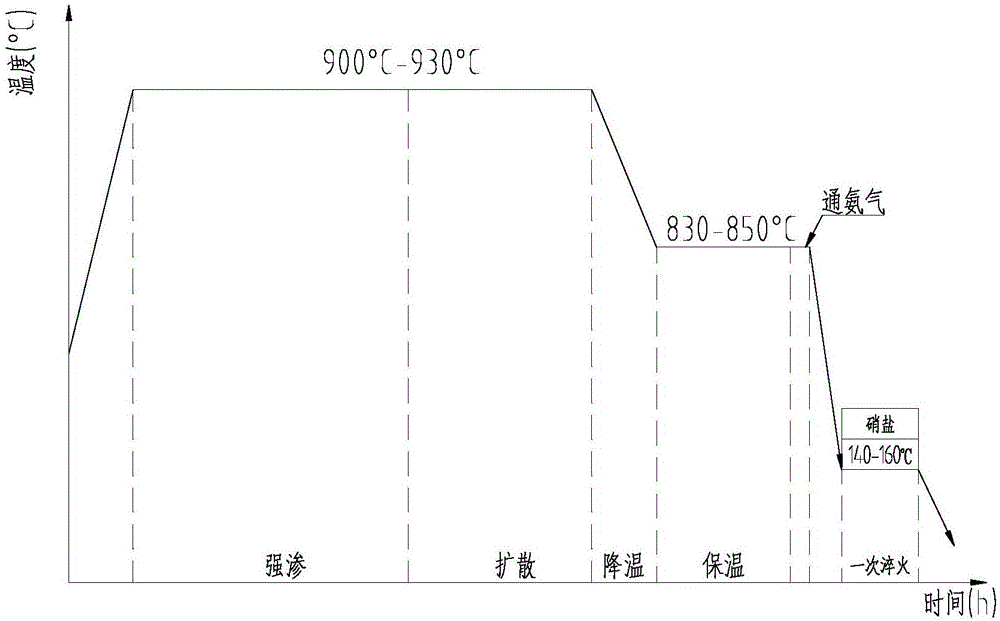

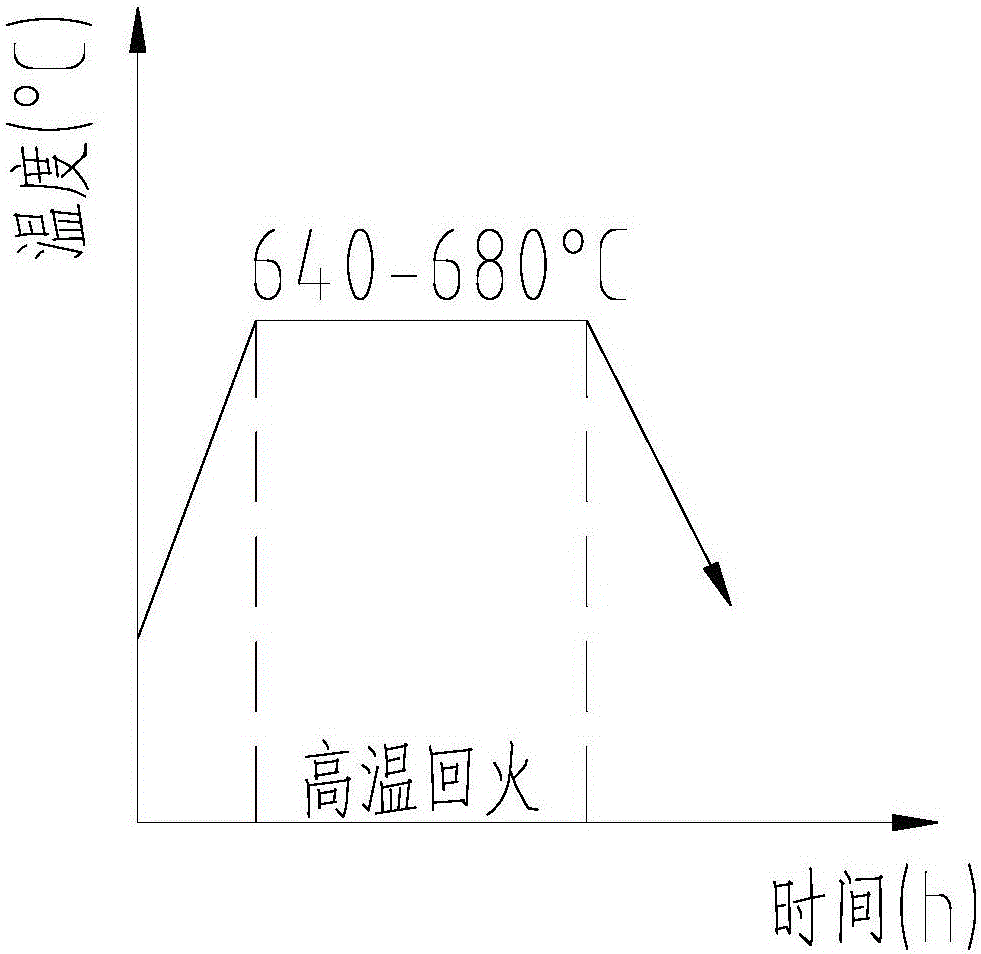

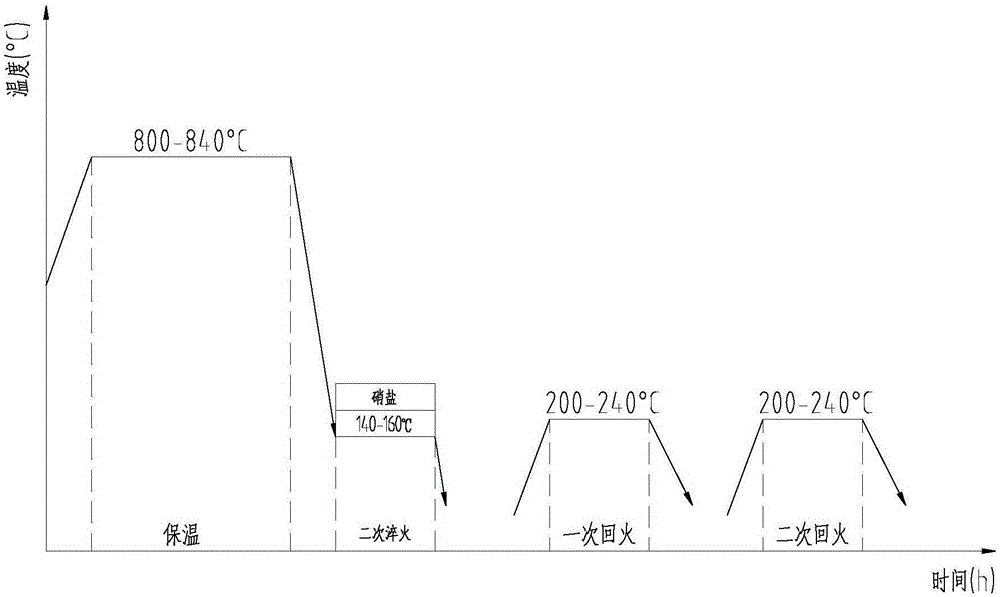

[0038]S1. Carburizing: The carburizing includes a pretreatment step and a carburizing step, and the carburizing step includes a strong infiltration stage and a diffusion stage.

[0039] S1-1 Pretreatment step: Clamp the cleaned workpiece on the heat treatment tool, and put it into the box-type carburizing furnace as a whole. The selected box-type carburizing furnace has a volume of 1.2m 3 . Turn on the power to raise the temperature, and turn on a large flow of nitrogen to replace the atmosphere in the furnace to reduce the content of oxygen and other oxid...

Embodiment 2

[0051] The invention discloses a process method for controlling the non-martensitic depth of a carburized workpiece, which comprises the following steps:

[0052] Clean the workpiece to be carburized in advance, especially to ensure that there is no oil and other impurities on the surface of the tooth profile, and at the same time, do anti-seepage treatment on the part of the workpiece that does not need to be carburized.

[0053] S1. Carburizing: The carburizing includes a pretreatment step and a carburizing step, and the carburizing step includes a strong infiltration stage and a diffusion stage.

[0054] S1-1 Pretreatment step: Clamp the cleaned workpiece on the heat treatment tool, and put it into the box-type carburizing furnace as a whole. The selected box-type carburizing furnace has a volume of 1.2m 3 . Turn on the power to raise the temperature, and turn on a large flow of nitrogen to replace the atmosphere in the furnace to reduce the content of oxygen and other oxi...

Embodiment 3

[0066] The invention discloses a process method for controlling the non-martensitic depth of a carburized workpiece, which comprises the following steps:

[0067] Clean the workpiece to be carburized in advance, especially to ensure that the surface to be carburized is free of any oil and other impurities, and at the same time, do anti-seepage treatment on the parts of the workpiece that do not need to be carburized.

[0068] S1. Carburizing: The carburizing includes a pretreatment step and a carburizing step, and the carburizing step includes a strong infiltration stage and a diffusion stage.

[0069] S1-1 Pretreatment step: Clamp the cleaned workpiece on the heat treatment tool, and put it into the box-type carburizing furnace as a whole. The selected box-type carburizing furnace has a volume of 1.2m 3 . Turn on the power to raise the temperature, and turn on a large flow of nitrogen to replace the atmosphere in the furnace to reduce the content of oxygen and other oxidizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com