Multi-station automatic water injection apparatus and control method thereof

An automatic water injection, multi-station technology, applied in the direction of using electric device flow control, non-electric variable control, flow control, etc., can solve the problems of high investment cost and maintenance amount, reduce investment cost and maintenance cost, The effect of reducing work intensity and improving the degree of centralized management of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] The invention provides a multi-station automatic water injection device and a control method thereof.

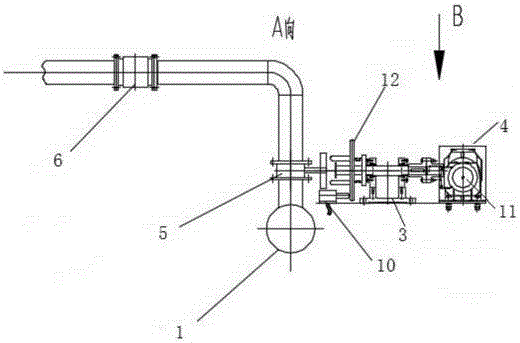

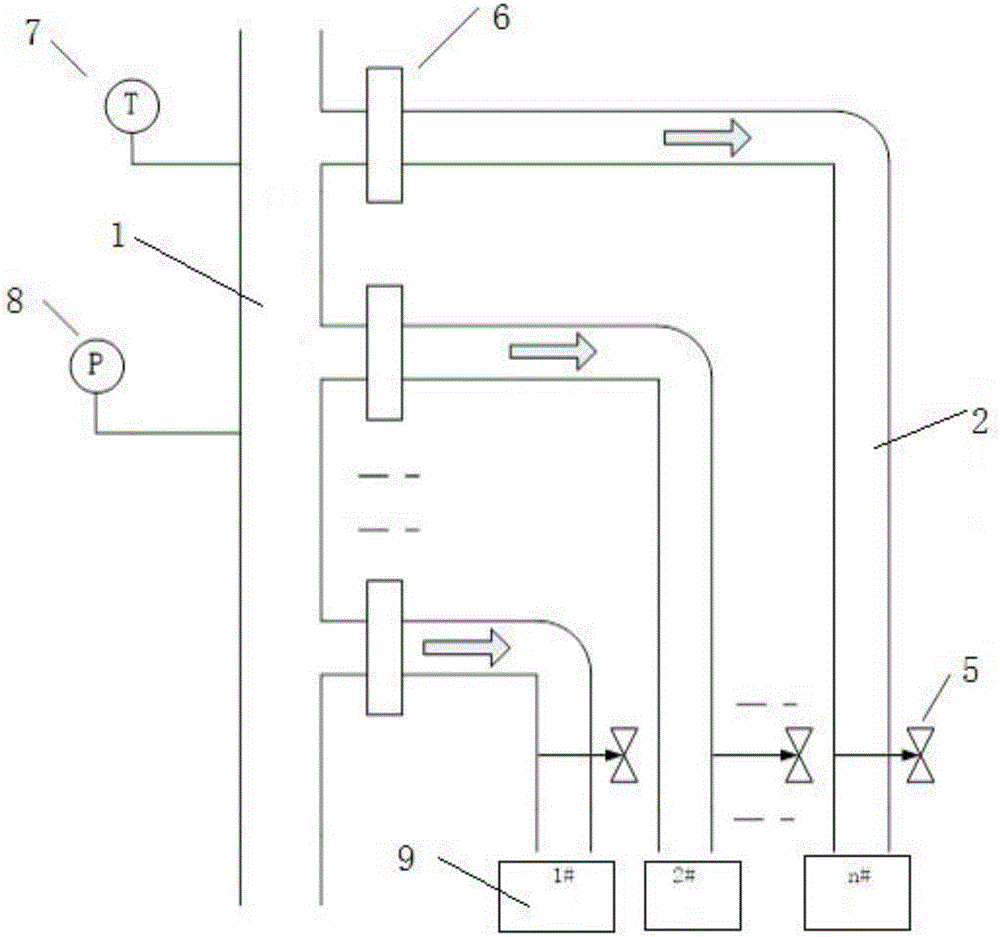

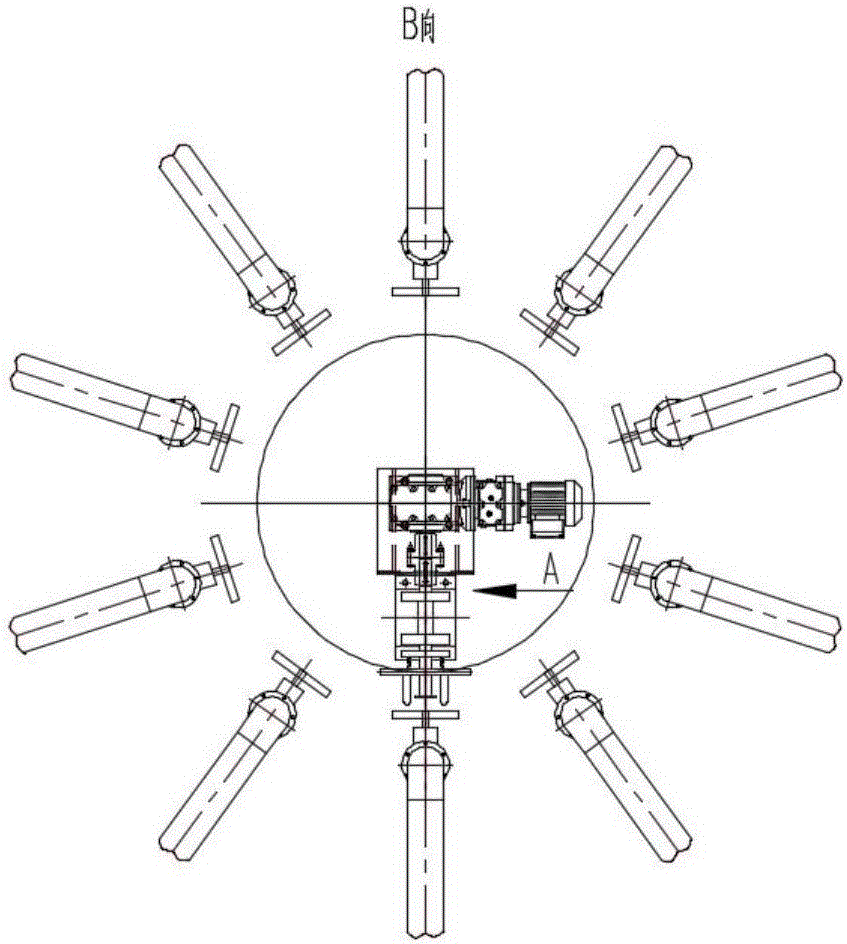

[0031] Such as figure 1 and figure 2 , image 3 As shown, in the device, the main water inlet pipe 1 is branched into more than one water well injection pipe 2, and a water well flowmeter 6 and a water injection flow limiting valve 5 are installed on the water well water injection pipe 2, and the water well water injection pipe 2 injects water into the water injection well 9, and the total inlet A thermometer 7 and a pressure gauge 8 are installed on the water pipe 1. The valve position selection mechanism 4 controls the water injection flow limiting valve 5 through the electric actuator 3. The water injection flow limiting valve 5 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com