Dangerous chemical raw material logistics storage management system and dangerous chemical raw material logistics storage management method based on Internet-of-things

A storage management system and chemical raw material technology, applied in the field of hazardous chemical raw material logistics storage management system, can solve the problems of slow information feedback, unscientific processing speed and method, imperfect management supporting facilities, etc., and achieve the effect of ensuring safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing.

[0030] Such as figure 1 As shown, a dangerous chemical raw material logistics storage management system based on the Internet of Things, including storage information monitoring system 1, data information transmission 2, information management system 3, dangerous accident pretreatment system 4, storage information monitoring system 1 connected to data information transmission 2. Data information transmission 2 is connected to information management system 3, and information management system 3 is connected to dangerous accident pretreatment system 4;

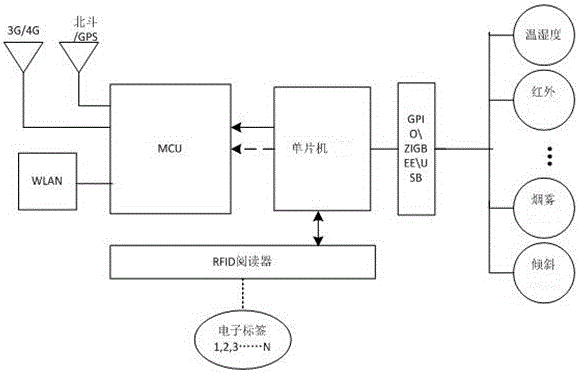

[0031] The storage information monitoring system 1 is used to monitor the storage environment of dangerous chemical raw materials and the dangerous goods themselves, and is completed by a single-chip microcomputer STM32, and the monitoring of the environment and itself is realized by externally loading high-sensitivity sensors and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com