High-precision pressure sensor experimental model and experimental method

A pressure sensor and experimental model technology, applied in teaching models, instruments, educational appliances, etc., can solve problems such as poor accuracy, low measurement accuracy, and outdated circuit design, and achieve large changes in space, cost reduction, and easy disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

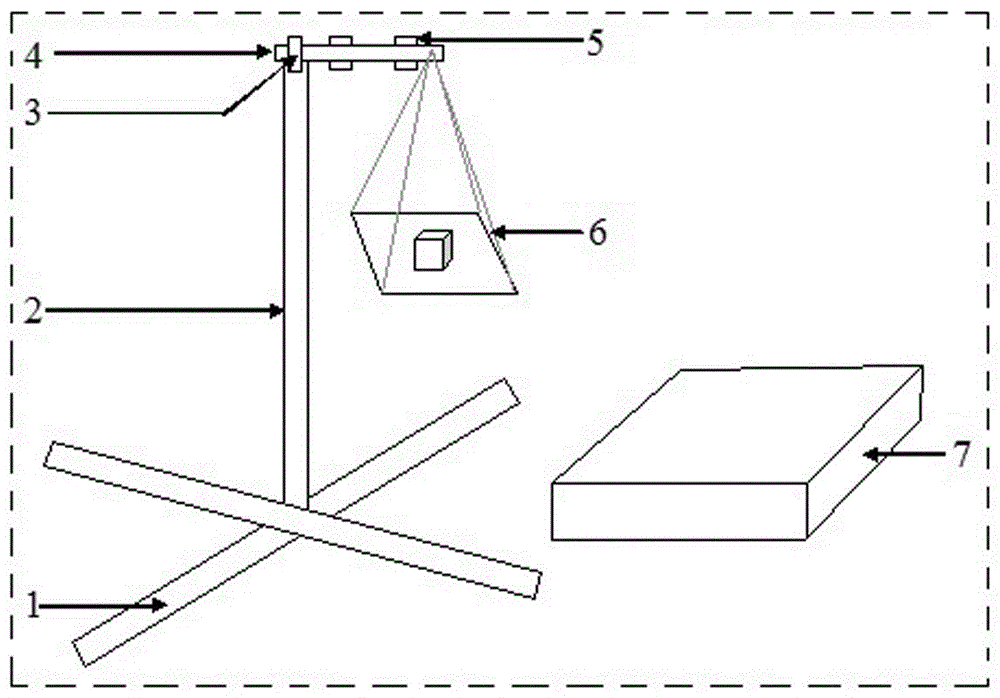

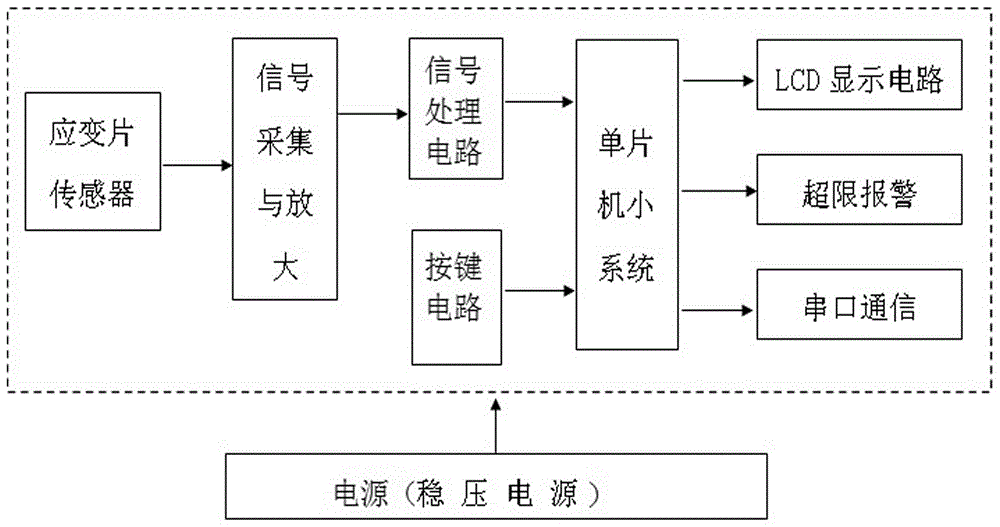

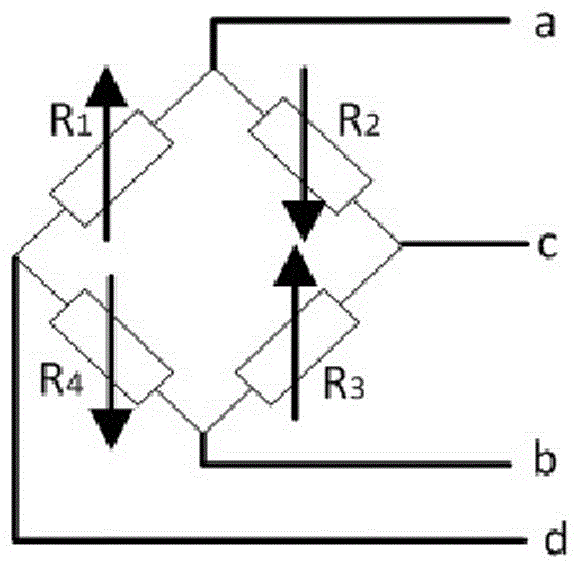

[0053] Refer to attached Figure 1~8 , the high-precision pressure sensor experimental model of the present invention includes a base, a support, a cantilever beam and a weighing pan, the support is arranged in the middle of the base, the cantilever beam is arranged at the top of the support, and one end of the cantilever beam is fixed on the support by bolts to form a cantilever structure. There is a hanging hole on the edge of the weighing pan, and the weighing pan is suspended on the other end of the cantilever beam through the hanging hole through a thin rope, and a strain gauge is set on the cantilever beam; the high-precision pressure sensor experimental model is also equipped with an independent detection system, It is used for pressure measurement and display; the strain gauge sensor is connected to the detection system, and the pressure change signal is transmitted to the detection system, and the detection system analyzes and processes the signal and displays or alarm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com