Large-aperture Gasar porous metal material low vibration noise water-cooled motor

A technology of porous metal and water-cooled motors, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of weakening the aerodynamic noise of the motor, poor heat exchange capacity, poor operation effect, etc., and achieve good shock absorption and sound absorption characteristics, Reduce vibration and noise, and enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

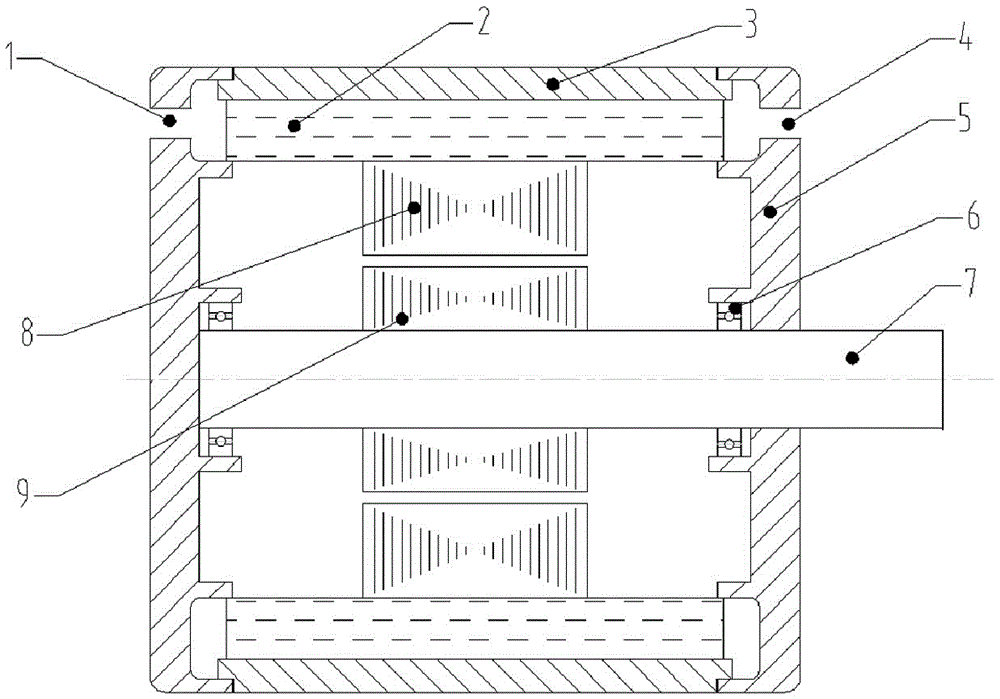

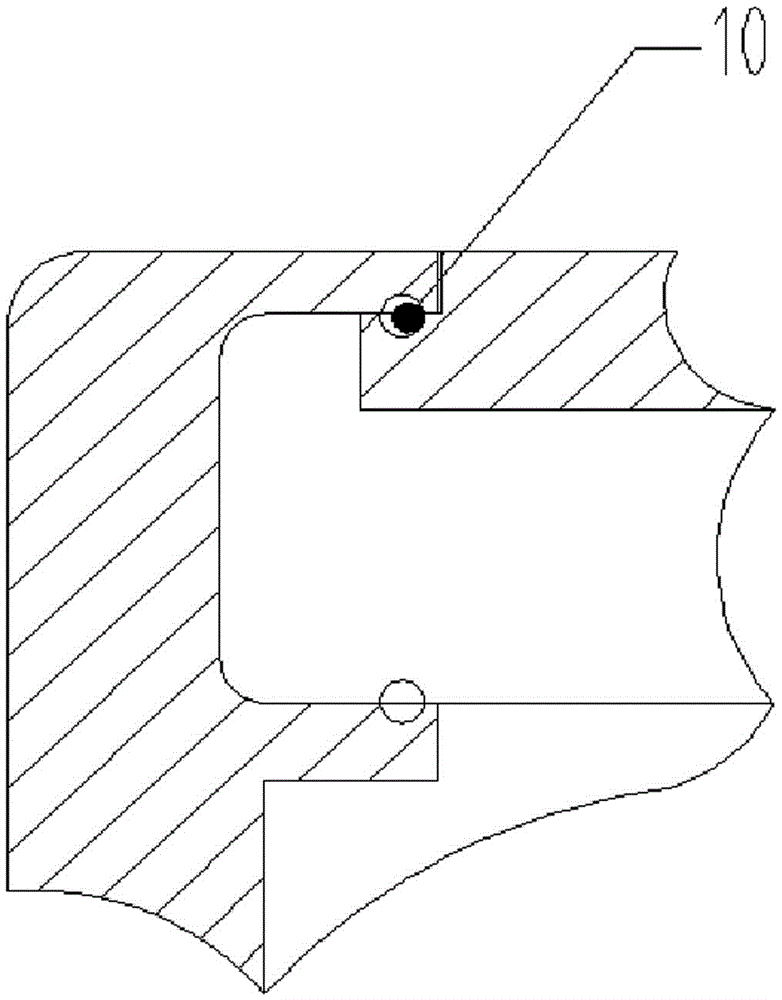

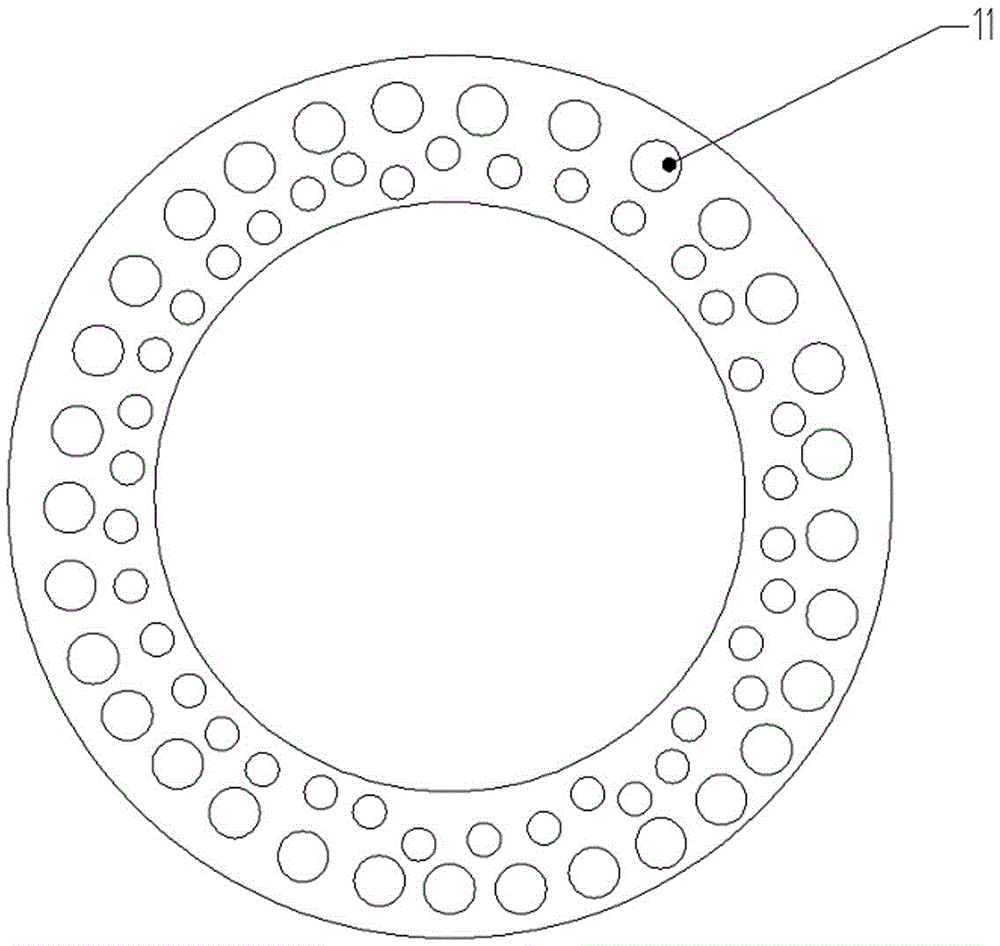

[0023] Such as figure 1 As shown, the present invention provides a large-aperture porous metal material low-vibration and noise water-cooled motor, including an end cover 3 and a stator 8, and a water-cooling channel 2 made of a porous structure material is formed between the end cover 3 and the stator 8.

[0024] The two sides of the motor end cover 3 are opened as the water inlet 1 and the water outlet 4 of the water cooling passage, and the water inlet 1 and the water outlet 4 communicate with the holes 11 in the water cooling passage 2 .

[0025] exist figure 1 Among them, the motor end cover 3 is opened as the water inlet 1 of the water cooling channel, and the other end cover is used as the water outlet 4 of the water cooling channel, so that the cooling water circulates in the motor cooling channel to reduce the temperature rise of the motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com