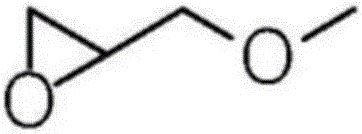

Novel epoxy compound, mixture, composition, and cured product comprising same, method for preparing same, and use thereof

An epoxy compound, epoxy group technology, applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, silicon organic compounds, etc., can solve the problem of insufficient heat resistance and processability, reduce CTE, Probability increase and other issues, to achieve the effect of excellent processing performance, excellent flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

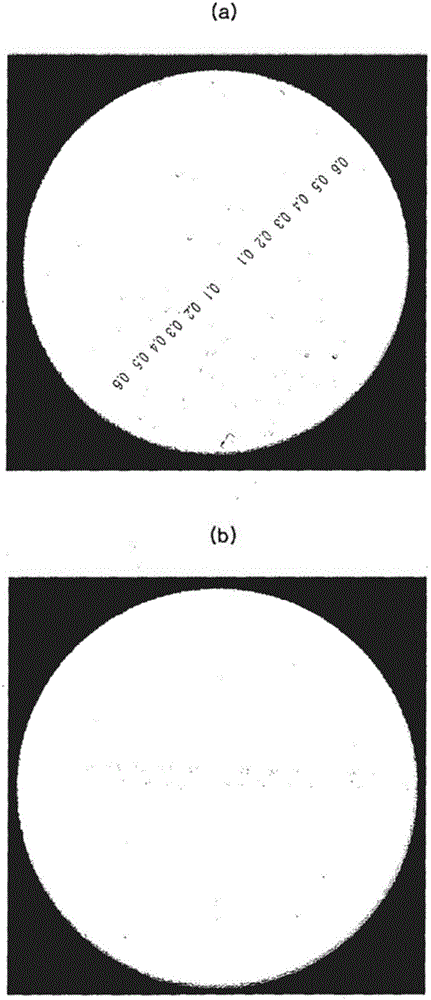

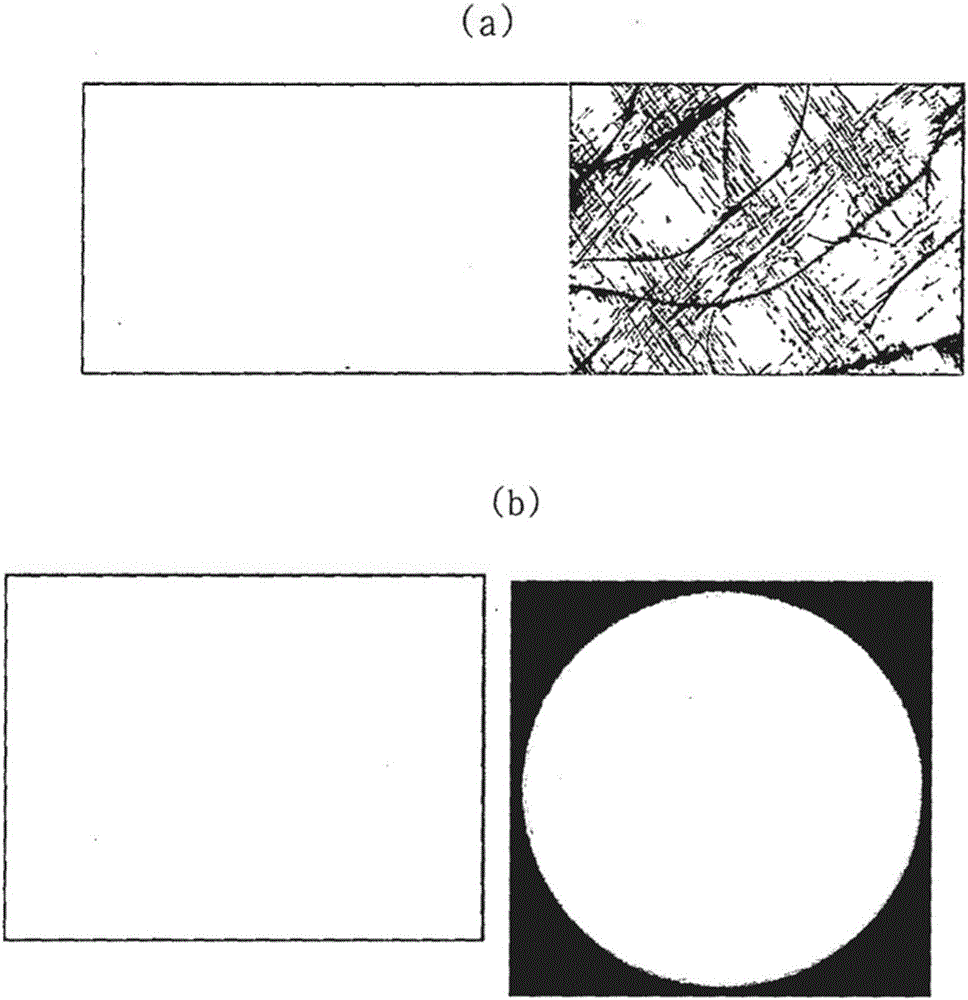

Image

Examples

Embodiment approach

[0616] Any epoxy composition provided according to aspects of the present invention may be used as a composition for electronic materials. The electronic material may include, but is not limited to, for example, substrates for semiconductors, films, prepregs, laminates in which a metal layer is provided on a substrate formed using a composition according to an example embodiment of the present invention, Encapsulation materials (encapsulation materials), electronic components such as printed circuit boards, etc. In addition, the epoxy composition can be used in various applications such as adhesives, paints, composites, and the like. According to another exemplary embodiment of the present invention, there is provided an electronic material comprising an epoxy composition containing an epoxy compound according to an exemplary embodiment of the present invention, or using the epoxy composition to form. Furthermore, there is provided a semiconductor device which includes the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com