A production process of a seamless steel pipe used for rolling an integral finned pipe

A production process, seamless steel pipe technology, applied in the production process field of finned tube raw material (base) tube, can solve the problems affecting the accuracy of heat exchanger, reduce the pressure bearing capacity, reduce the safety factor, etc., and achieve the elimination of leakage and explosion The effect of hidden dangers, prolonging the service life cycle, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

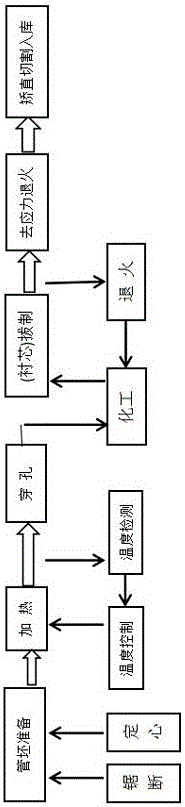

[0036] like figure 1 Shown, the production process of seamless steel pipes for rolling integral finned tubes, the production process includes the following steps:

[0037] Before the raw material pipe is ready to be pierced, the tube blank must be sawed off with a sawing machine. The sawing length is determined according to the process length of the finished tube; The diameter of the centering hole is 1 / 3 of the diameter of the tube blank, and the length of the centering hole is 10-15 mm;

[0038] After the centering treatment, the tube billet is sent to the continuous heating furnace for heating, and the heating temperature is set according to the different specifications of the tube billet.

[0039] Similarly, if 10 or / and 20 steel, the heating temperature is set to 1220±15°C, if 35 or / and 45 low-alloy steel, the heating temperature is set to 1200±15°C, and the heating temperature is detected in real time by the real-time detection device , using closed-loop automatic equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com