Multi-head joggling machine for woodworking

A mortise joint machine and multi-head technology, applied in multi-purpose machinery, wood processing equipment, tenon making devices, etc., can solve the problems of poor processing quality and achieve the effect of improving multi-functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

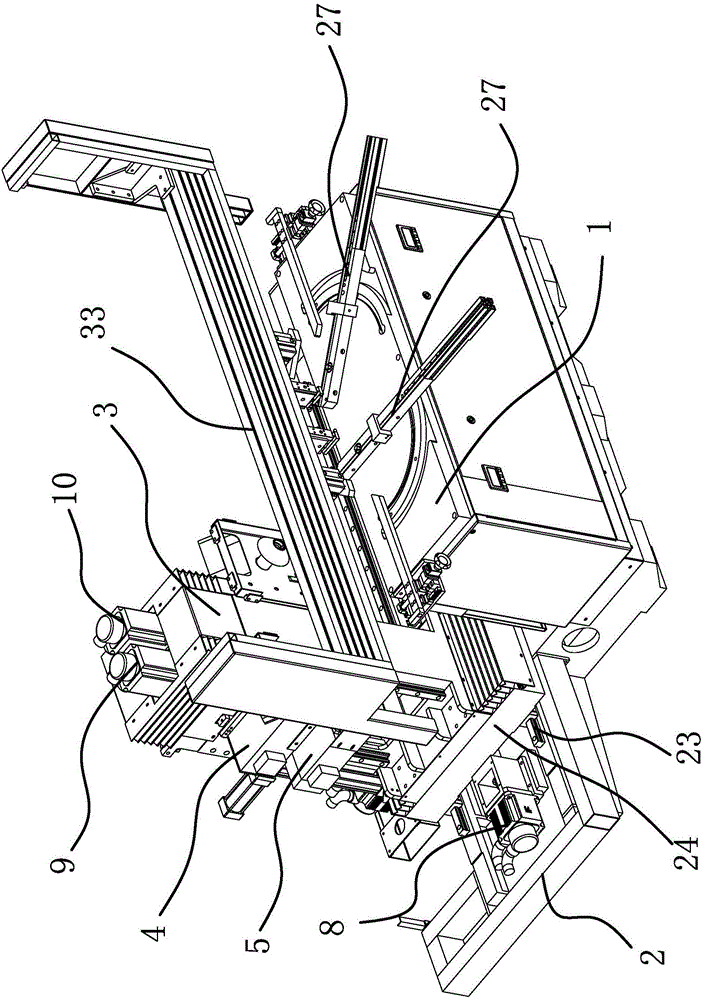

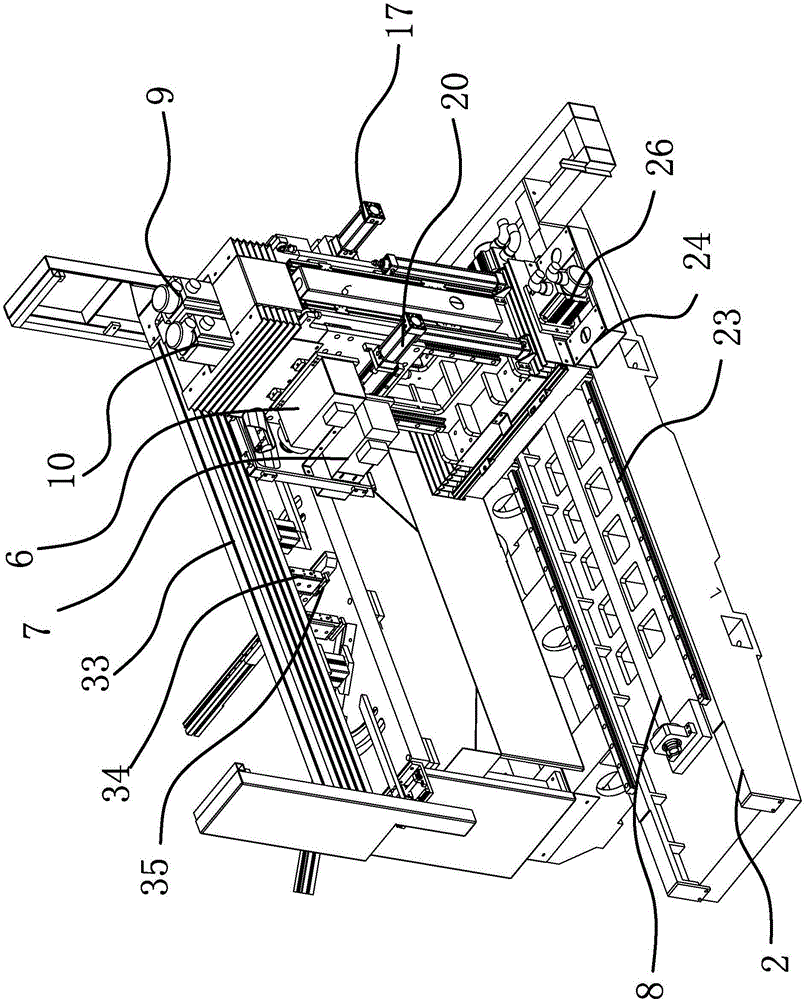

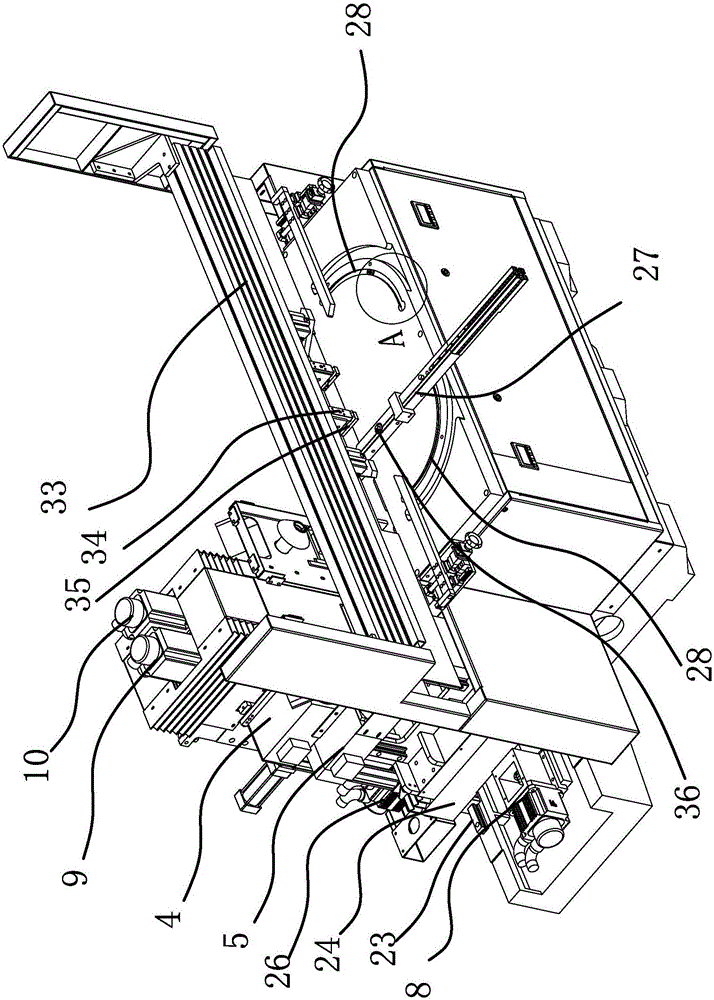

[0031] like Figure 1-Figure 5 As shown, the tenon joint machine of this embodiment includes a workbench 1 at the front and a base 2 at the rear. The base 2 is provided with a vertical support 3, and the support 3 is slidably connected to the base 2 in the horizontal direction. And a power source 8 for driving the former to move relative to the latter is arranged between the two. The base 2 is fixed with a guide rail three 23 arranged horizontally and horizontally, the guide rail three 23 is slidably connected with a main supporting board 24, the power source one 8 is connected with the main supporting board 24 and can drive the main supporting board 24 to move along the guide rail three 23, The main supporting plate 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com