Box-shaped part molding mold with grid rib framework

A technology for forming molds and grid ribs, which is applied in the field of box-shaped parts forming molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

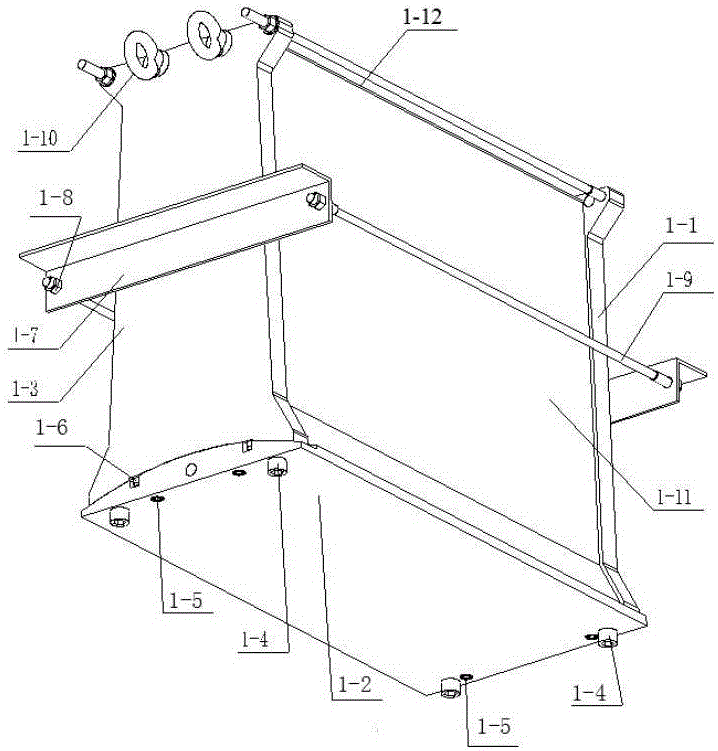

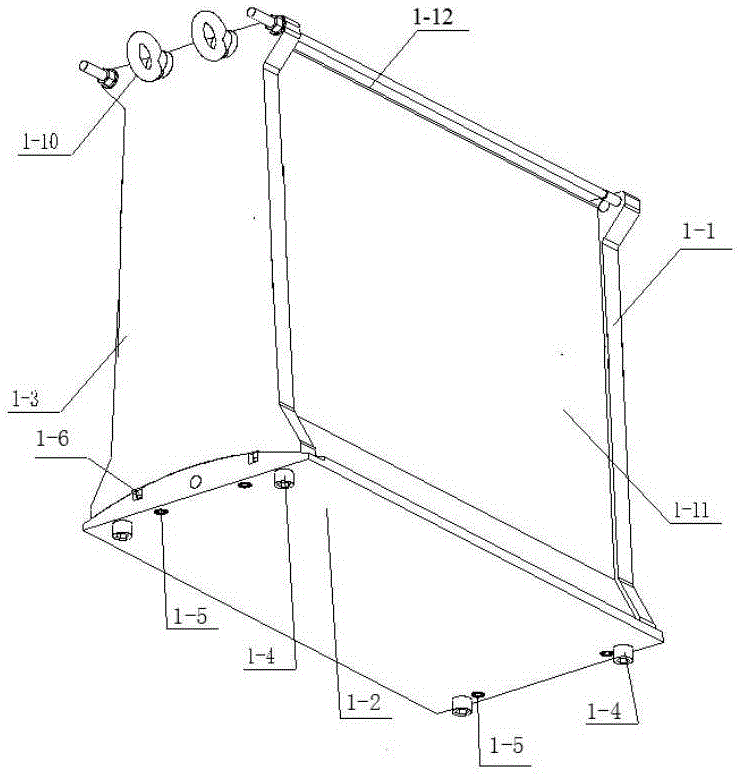

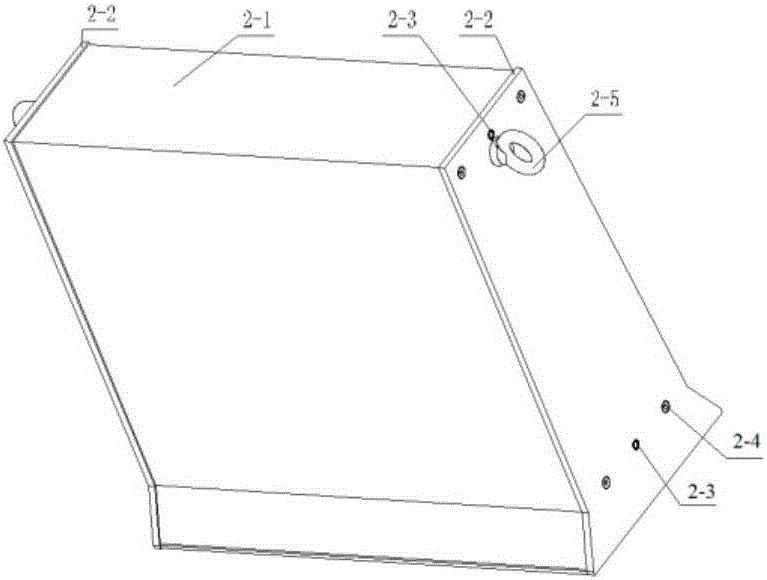

Image

Examples

Embodiment Construction

[0090] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0091] In technology, the present invention involves the following meanings:

[0092] Bonding, using heat to glue the two parts together. The bonding process is required: the front and rear panels of the outer skin 16-1 and the prefabricated inner skin 10-1, the inner skin 11-1 of the side skin, the outer skin 15-1 of the side skin, and the inner skin of the bottom skin The skin 14-1, the outer skin of the bottom skin, and the grid rib skeleton 17-1 are formed by solidification, and the two are connected together by bonding to form a whole.

[0093] Curing, the two parts are connected together by adding temperature and high pressure. The curing process is required: inner skin prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com