Preparation method of rooting synergist major-element liquid water-soluble fertilizer

A technology of a large number of elements and synergists, applied in the direction of liquid fertilizer, urea compound fertilizer, nitrogen fertilizer, etc., to achieve the effect of increasing the contact area, flexible formula, and conducive to root growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

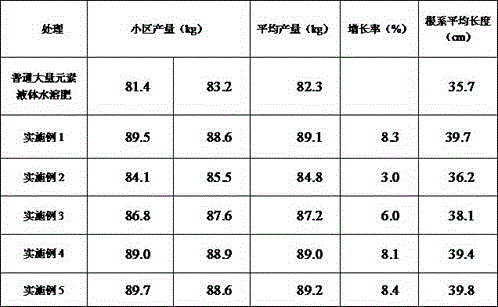

Examples

Embodiment 1

[0034] Prepare product A: join the rooting agent and the wetting emulsifier into the stirred tank filled with the synergist according to a certain mass ratio, the mass ratio of the rooting agent, the wetting emulsifier and the synergist is 20:7:73, stir After homogenization, product A is obtained;

[0035] Prepare a synergist with rooting effect: start stirring at room temperature and slowly add a thickener to product A, the mass ratio of product A and thickener is 100:5, stir until the thickener is completely dispersed, and obtain a rooting effect. synergist;

[0036] Prepare macroelement water-soluble fertilizer raw materials: weigh macroelements and trace elements respectively according to the mass ratio of 90:10 to obtain macroelement water-soluble fertilizer raw materials;

[0037] Preparation of rooting synergist macroelement liquid water-soluble fertilizer: add macroelement raw materials and rooting synergist with rooting effect to water containing additives according ...

Embodiment 2

[0039] Prepare product A: join the rooting agent and the wetting emulsifier into the stirred tank filled with the synergist according to a certain mass ratio, the mass ratio of the rooting agent, the wetting emulsifier and the synergist is 20:7:73, stir After homogenization, product A is obtained;

[0040] Prepare a synergist with rooting effect: start stirring at room temperature and slowly add a thickener to product A, the mass ratio of product A and thickener is 100:5, stir until the thickener is completely dispersed, and obtain a rooting effect. synergist;

[0041] Prepare macroelement liquid water-soluble fertilizer raw material: weigh macroelement and trace element respectively according to the mass ratio of 90:10 to obtain macroelement liquid water-soluble fertilizer raw material;

[0042]Preparation of rooting synergist macroelement liquid water-soluble fertilizer: add macroelement raw materials and rooting synergist with rooting effect to water containing additives a...

Embodiment 3

[0044] Prepare product A: join the rooting agent and the wetting emulsifier into the stirred tank filled with the synergist according to a certain mass ratio, the mass ratio of the rooting agent, the wetting emulsifier and the synergist is 20:7:73, stir After homogenization, product A is obtained;

[0045] Prepare a synergist with rooting effect: start stirring at room temperature and slowly add a thickener to product A, the mass ratio of product A and thickener is 100:5, stir until the thickener is completely dispersed, and obtain a rooting effect. synergist;

[0046] Prepare macroelement liquid water-soluble fertilizer raw material: weigh macroelement and trace element respectively according to the mass ratio of 90:10 to obtain macroelement liquid water-soluble fertilizer raw material;

[0047] Preparation of rooting synergist macroelement liquid water-soluble fertilizer: add macroelement raw materials and rooting synergist with rooting effect to water containing additives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com