Blind window plate with diatomaceous earth and method for preparing blind window plate

A technology of shutters and diatomite, applied in the field of shutters, can solve the problems of easy aging, short service life, high price, etc., and achieve the effects of excellent thermal stability and mechanical properties, long service life and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

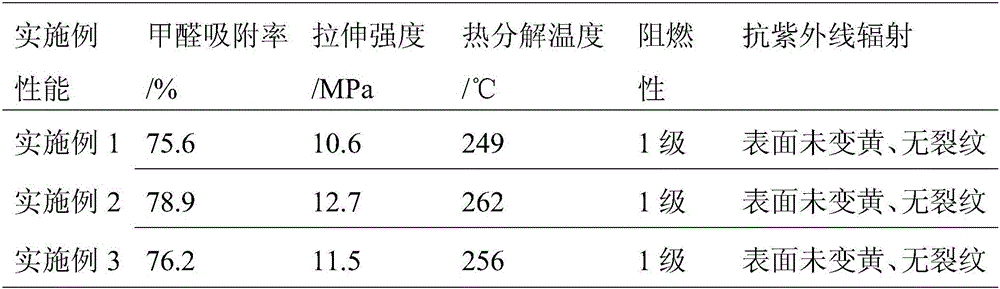

Examples

Embodiment 1

[0021] Diatomite louver, the material of this louver consists of 100 parts by weight of diatomite (800 mesh), 100 parts by weight of PPC, 4 parts by weight of ammonium polyphosphate, 3 parts by weight of epoxidized soybean oil, 2 parts by weight of Montmorillonite (800 mesh), 2 parts by weight of lignin, 1 part by weight of calcium carbonate (800 mesh), 0.5 part by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168 and UV944 of 1 part by weight composition.

[0022] The preparation method of the above-mentioned diatomite louver sheet is as follows: adding the raw materials into the mixing mixer according to the weight ratio, stirring and mixing evenly, and then extruding and granulating with a twin-screw extruder to obtain pellets, and then feeding the pellets into In the extruder, extrude strips and emboss to obtain diatomite louvers. The temperature of the screw extruder: 170°C in the first zone, 175°C in the second zone, 175°C in the third zone, 175°C in the ...

Embodiment 2

[0025] Diatomite louver, the material of this louver consists of 100 parts by weight of diatomite (1000 mesh), 120 parts by weight of PPC, 5 parts by weight of ammonium polyphosphate, 1 part by weight of melamine, 5 parts by weight of epoxy The montmorillonite (600 mesh) of soybean oil, 4 weight parts, the lignin of 4 weight parts, the calcium carbonate (700 mesh) of 1.5 weight parts, the antioxidant 1076 of 1 weight part, the antioxidant 618 of 0.2 weight part , 1.5 parts by weight of UV324 and 3 parts by weight of toner (blue).

[0026] The preparation method of the above-mentioned diatomite louver sheet is as follows: adding the raw materials into the mixing mixer according to the weight ratio, stirring and mixing evenly, and then extruding and granulating with a twin-screw extruder to obtain pellets, and then feeding the pellets into In the extruder, extrude strips and emboss to obtain diatomite louvers. The temperature of the screw extruder: 170°C in the first zone, 175°C...

Embodiment 3

[0029] Diatomite louver, the material of this louver consists of 100 parts by weight of diatomite (1000 mesh), the PPC of 105 parts by weight, the ammonium polyphosphate of 4.5 parts by weight, the epoxy soybean oil of 4 parts by weight, 4 parts by weight Montmorillonite (700 mesh), 3 parts by weight of lignin, 1.5 parts by weight of calcium carbonate (80 mesh), 1 part by weight of antioxidant 1076, 0.3 parts by weight of antioxidant 618 and UV324 of 3 parts by weight .

[0030] The preparation method of the above-mentioned diatomite louver sheet is as follows: adding the raw materials into the mixing mixer according to the weight ratio, stirring and mixing evenly, and then extruding and granulating with a twin-screw extruder to obtain pellets, and then feeding the pellets into In the extruder, extrude strips and emboss to obtain diatomite louvers. The temperature of the screw extruder: 170°C in the first zone, 175°C in the second zone, 175°C in the third zone, 175°C in the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com