Fastening connection assembly and structure, mounting and dismounting method, crankshaft connecting-rod mechanism, rail structure, bone connecting device and bone connection method

A technology for fastening connections and components, which is applied in the direction of connecting components, threaded fasteners, locking fasteners, etc., can solve the problems of no use value, and the difficulty of the anti-rotation sleeve, and achieves quick removal, reduced size, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

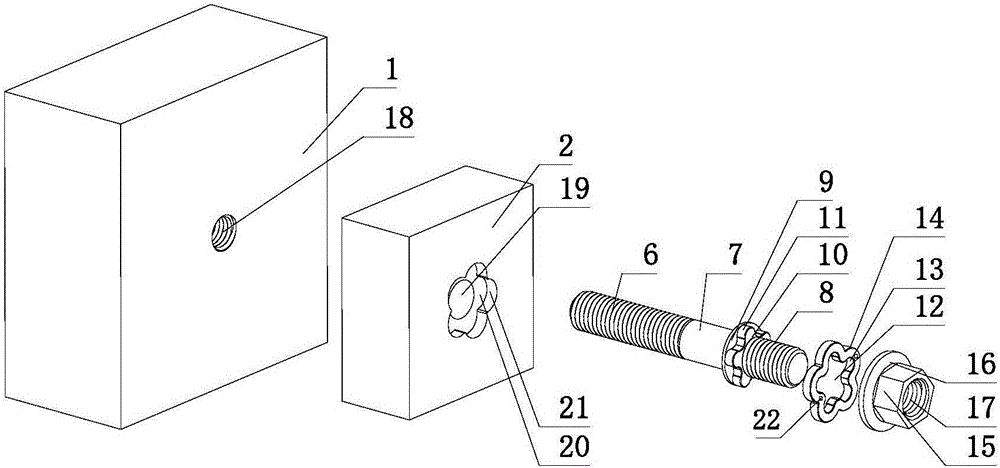

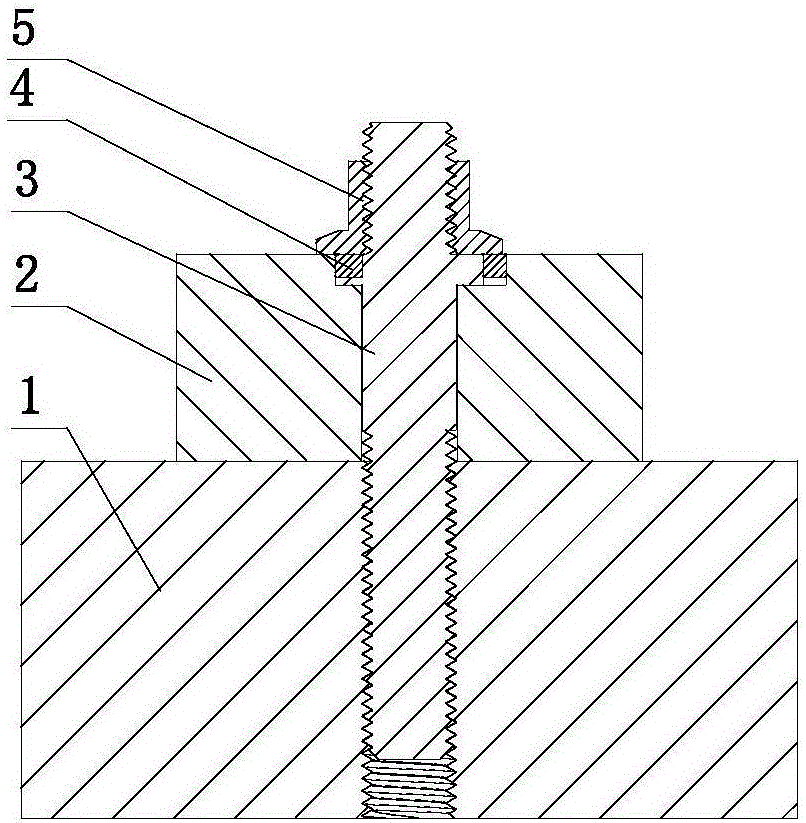

[0208] Such as figure 1 , figure 2 As shown, a fastening connection structure includes a mother body 1, an appendage 2, and a fastening connection assembly.

[0209] The fastening connection assembly includes the screw rod 3, the anti-rotation sleeve 4, and the stopper of the anti-rotation sleeve. The stopper of the anti-rotation sleeve is a blocking nut 5 .

[0210] The screw 3 includes a first external threaded part 6 , a polished rod part 7 , a stopper against rotation and a second external threaded part 8 arranged in sequence. The anti-rotation resisting portion includes a cylindrical resisting circular convex ring 9 and a spline-shaped anti-rotation portion 10 , the anti-rotation portion 10 is connected to the second external thread portion 8 . Five protrusions are formed on the outer periphery of the anti-rotation portion 10 , and each protrusion forms a first anti-rotation portion 11 . The resisting ring 9 protrudes radially from the polished rod portion 7 and the ...

Embodiment 2

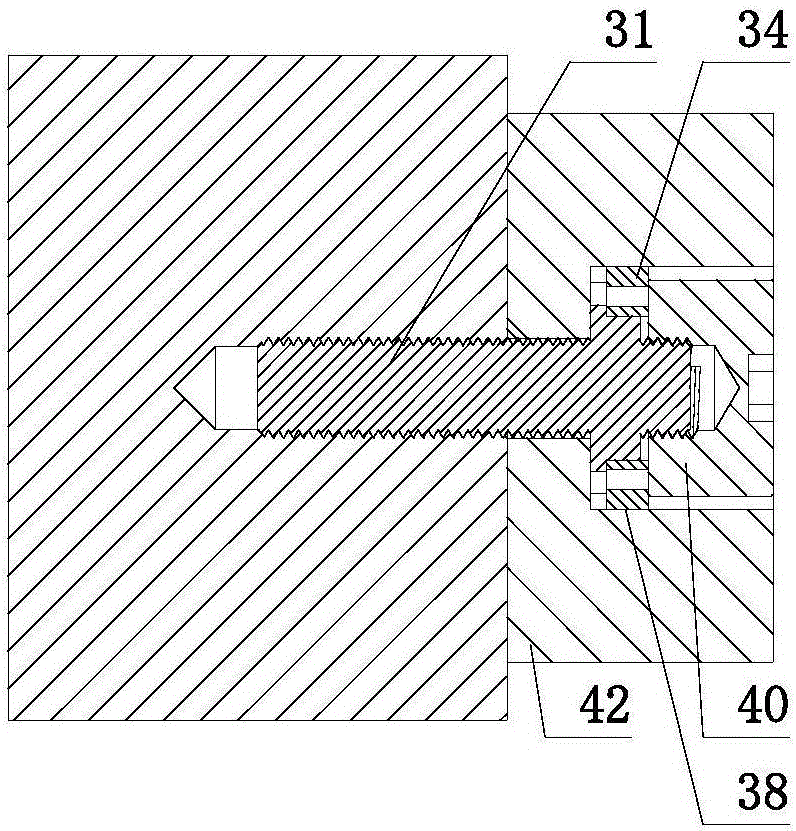

[0221] Such as image 3 , Figure 4 As shown, the difference from Embodiment 1 is that the outer circumference of the anti-rotation portion 32 of the screw 31 is a regular hexagon, and the six planes on the outer periphery of the anti-rotation portion 32 form six first anti-rotation portions 33 arranged in the circumferential direction.

[0222] The hole wall of the anti-rotation through hole 35 of the anti-rotation sleeve 34 cooperates with the outer periphery of the anti-rotation part 32, and the positive hexagonal hole, six planes on the hole wall of the anti-rotation through hole 35 form six circumferentially arranged and the first anti-rotation The second anti-rotation part 36 matched with the part 33. The outer circumference of the anti-rotation sleeve 34 is an intersecting structure of two regular hexagons with the same structure and rotated by 30°. The outer circumference of the anti-rotation sleeve 34 forms twelve pointed-shaped convex teeth, and each pointed-shaped ...

Embodiment 3

[0225] Such as Figure 5 , Figure 6 As shown, the difference from Embodiment 2 is that the stopper of the anti-rotation sleeve is a resisting screw 51 . The screw 52 includes a first external threaded portion 53 and a rotation-preventing resisting portion 55 arranged in sequence. A threaded hole 56 is provided on the end surface of the anti-rotation resisting part 55 away from the end of the first external threaded part 53, and the external threaded part 57 of the resisting screw 51 is threadedly connected with the threaded hole 56 on the screw rod 52, and the screw head 58 of the resisting screw 51 The maximum outer diameter is greater than the minimum inner diameter of the anti-rotation through hole 59 , and the screw head 58 of the resisting screw 51 axially limits the anti-rotation sleeve 60 . The resisting screw 51 is completely accommodated in the first anti-rotation hole 62 of the appendage 61 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com