Infrared detection method for high temperature damage of concrete

A technology of infrared detection and high-temperature damage, which is applied in the direction of applying stable tension/pressure to test material strength, preparation of test samples, and measuring devices, etc., to achieve accurate analysis, rapid detection, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further illustrated by the following examples, but not limited to the following examples.

[0058] 1. Principle of the present invention:

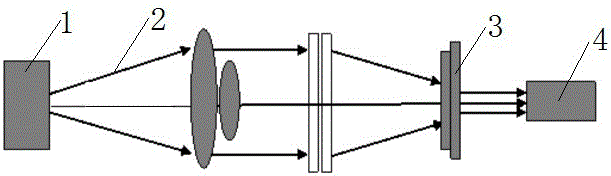

[0059] The present invention adopts the basic principle of infrared hot line detection as follows: infrared radiation is an electromagnetic wave with a wavelength between 0.75 and 1000 μm. In nature, all objects above absolute zero (-273°C) radiate infrared energy continuously, and its quantity is closely related to the temperature of the object. Based on this law, infrared detection technology has developed rapidly and has been widely used, especially for concrete materials with poor thermal conductivity and high surface emissivity, the detection sensitivity of infrared thermal imaging is very high.

[0060] Firstly, the TH9100WV thermal imaging camera is used to scan and detect the concrete structural members after the fire. In fact, infrared thermal imaging is a temperature distribution map of the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com